45

8. Maintenance

See the maintenance manual for the specific maintenance items and procedures.

8.1 Instructions on maintenance

★

It is necessary to perform regular checks and maintenance to keep the performance of the

machine at optimum.

★

Checks and maintenance are often neglected, so it is better to find the problems early and

solve them in time.

★

Use the spare parts provided or approved by HANGCHA GROUP CO., LTD.

★

When changing or adding oil, do not use oil which is not the same as the original.

★

The waste

oil and fluid and the old lithium

-

ion battery should be disposed of in accordance with the local

laws and regulations, rather than disposed of at will.

★

Develop a comprehensive maintenance and repair plan.

★

Complete records should be made after each maintenance and repair.

★

Only trained and approved service personnel can repair the machine.

★

Unless otherwise detailed, the operator should perform maintenance according to the

following requirements:

1. The platform should be placed on a flat and level surface.

2. The platform should be stationary.

3. Turn the key switch of the ground controller to the “OFF” position and pull out the key. Then

cut off all power to the machine.

8.2 Table of maintenance schedules

There are four maintenance cycles for this machine including daily, quarterly, semi

-

annually and

annually. Definitions are listed as follows:

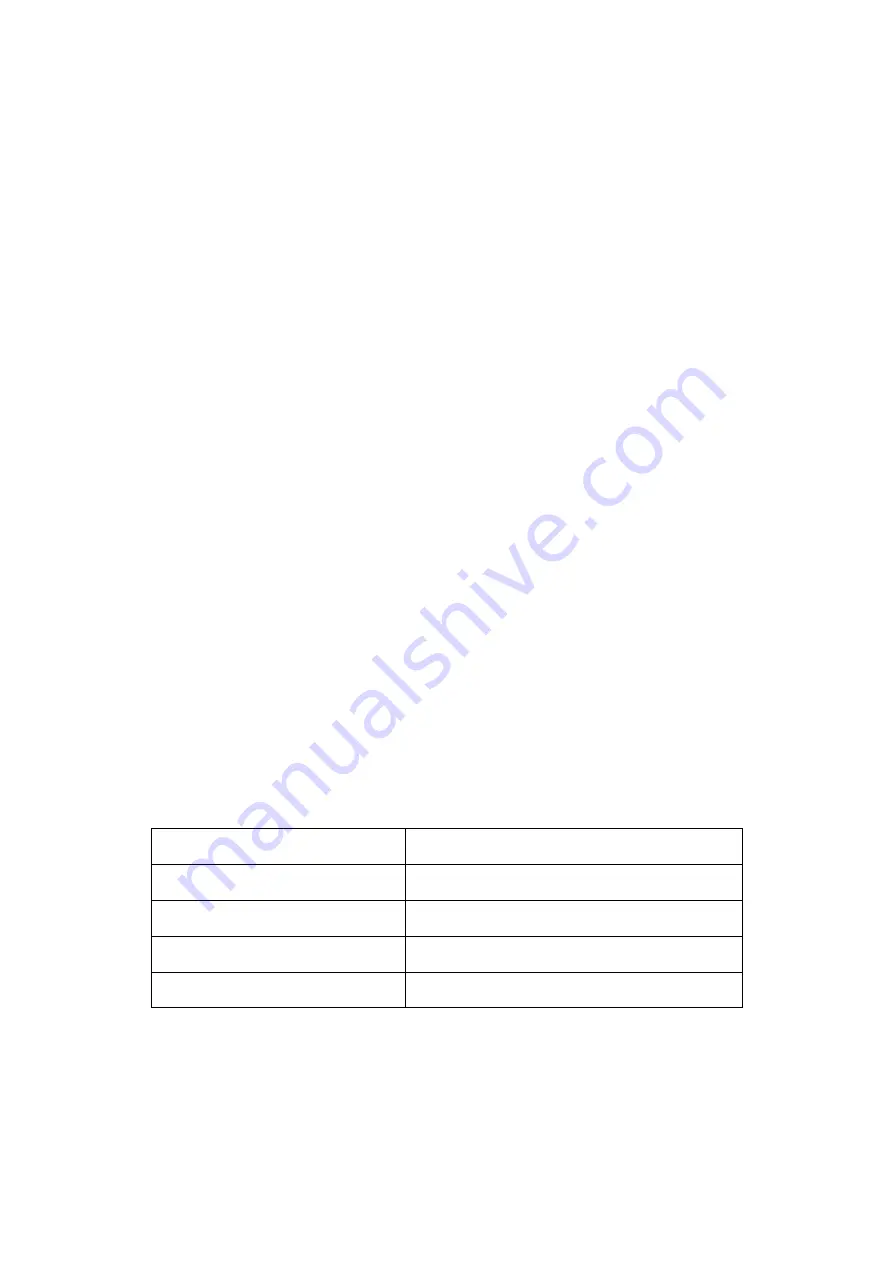

Maintenance Item

Maintenance Cycle

A

Once every 8 working hours (or daily)

A+B

Once every 250 working hours (or quarterly)

A+B+C

Once every 500 working hours (or semi

-

annually)

A+B+C+D

Once every 1,000 working hours (or annually)