HQ Fusion

™

User Manual 1.0

Page 6

Inserting (or changing) the Needle

Check that all power is turned off.

1.

Move the needle bar to the highest position by turning the

front or rear hand wheel or pressing the needle up/down

control on the handles (prior to turning the power off).

2.

Loosen the needle-bar-clamp thumb-screw (see Photo 4).

3.

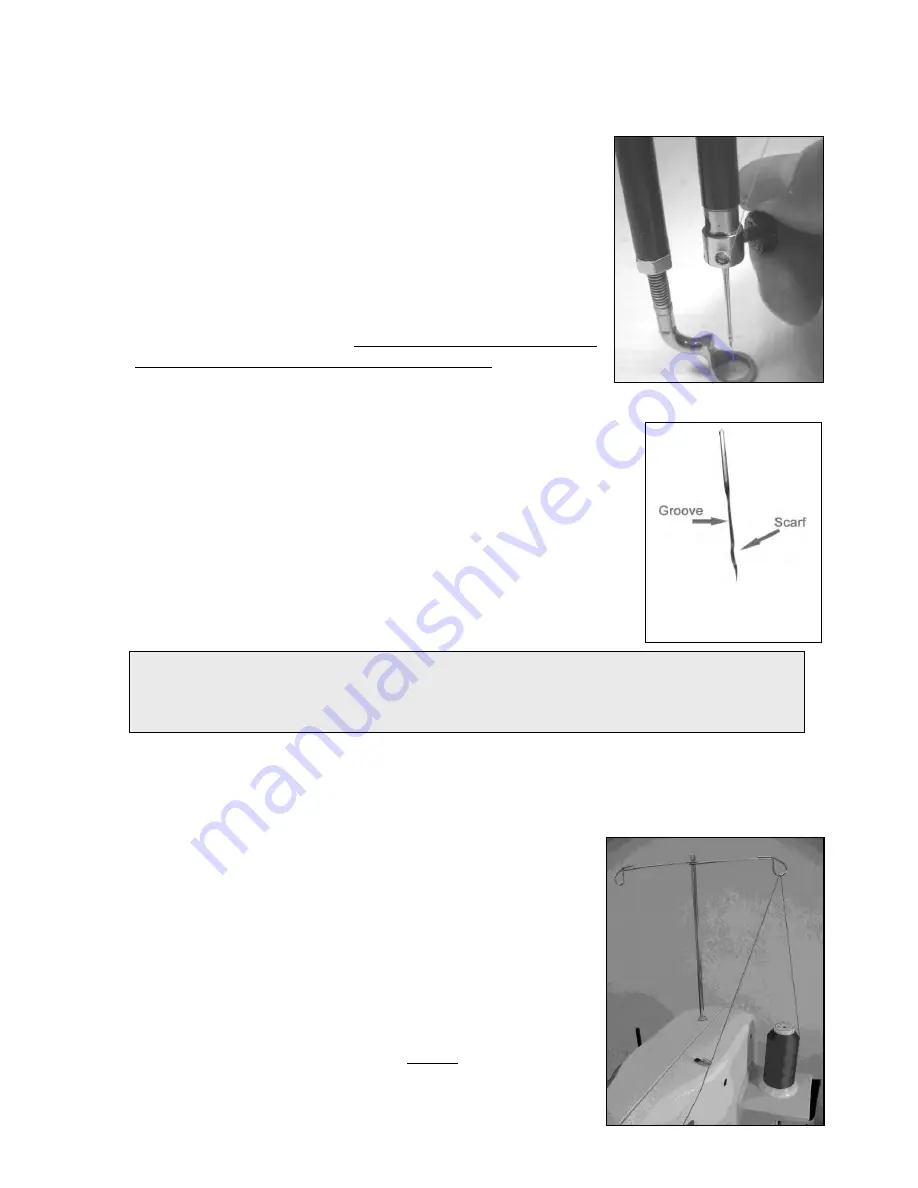

With the scarf (small ground-out section/dip on the back

side of the needle just above the needle eye) facing

toward the back hand-wheel side of the machine, and the

long groove down the front of the needle facing the bobbin

case side (see diagram E), push the needle all the way up

into the needle bar – until it can go no farther.

4.

Carefully

tighten the needle bar clamp screw. Over-tightening

the needle-clamp screw will result in damaged threads

stripping the hole. Stripped holes and damaged threads are

not covered under warranty. Another side-effect of damaged

threads from over tightening is that the needle may be very

tight when inserted up into the needle bar. To avoid over

tightening the screw,

finger tighten only

.

Note:

Changing the needle is recommended for each new quilt

loaded on the machine or any time the needle becomes bent, dull

or burred.

Adjusting the Hopping Foot

The foot is adjusted at the factory and should not be moved without consulting the

manufacturer.

Installing the Thread Mast

Locate the threaded hole on top of the machine near the

rear by the hand wheel. The thread mast comes with the

washer and nut on it. Remove the nut and washer, replace

the nut onto the mast and then place the washer under the

nut and onto the machine painted surface. The washer

protects the painted surface when the nut is tightened.

Tighten the mast clockwise until it is securely in place. Use

the nut to secure the mast to the machine.

Note:

The eyelets of the thread mast MUST be centered

over the spool pins – so the cone will not pull, turn or tilt

causing thread tension problems (see Photo 5).

Important: Check the needle to confirm it is fully inserted. The needle bar has a stop/sight

hole above the needle bar clamp screw – make sure the needle is touching the top of the

stop/sight hole. If it is not, the machine timing will be off and it may be possible for the

needle to collide with internal parts causing damage not covered by warranty

.

Photo 5

Diagram E

Photo 4