Supplied By www.heating spares.co Tel. 0161 620 6677

11

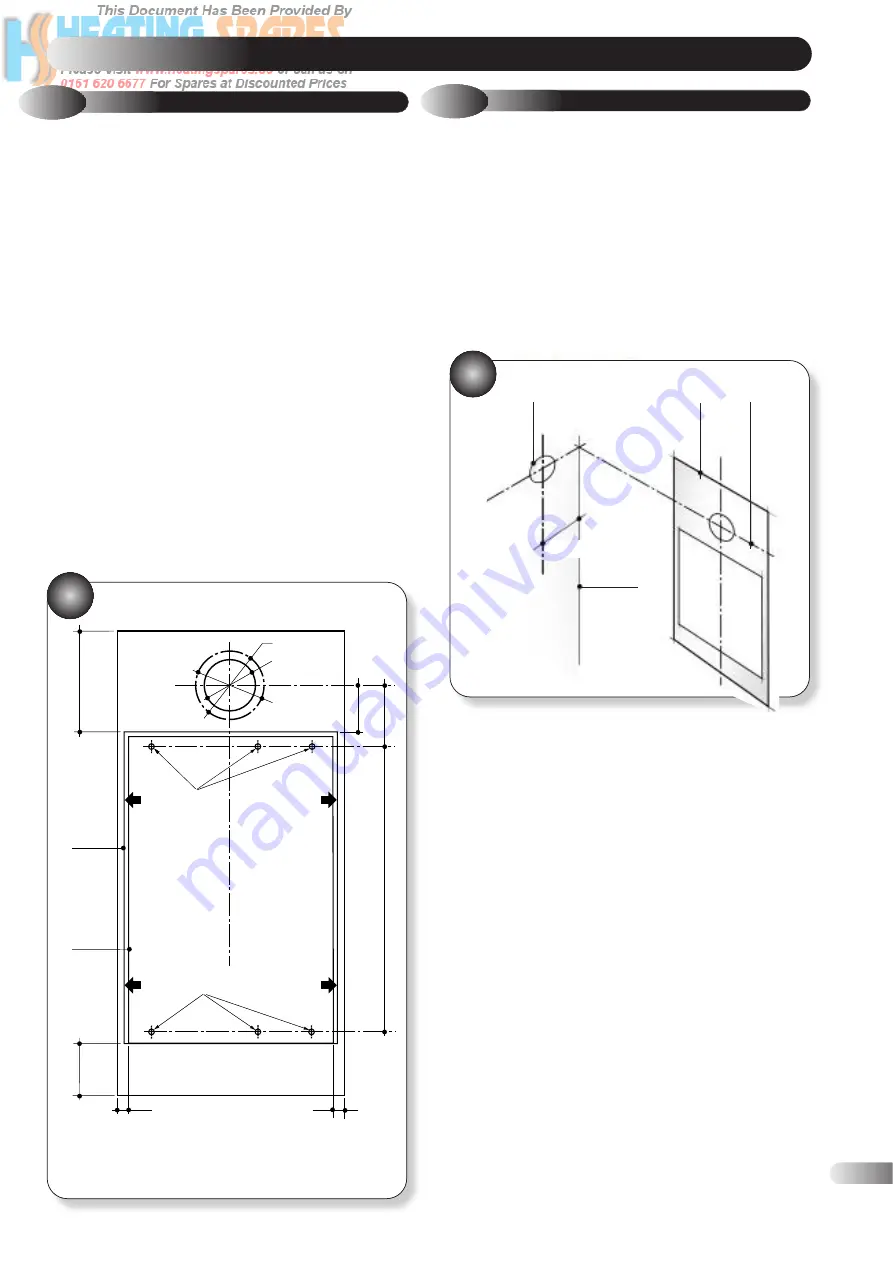

INSTALLING THE APPLIANCE

4

4.2

PREPARING THE WALL

Before installing the appliance ensure that the chosen location is

suitable (Section 3.2) and that the requirements for flue position,

(Section 3.3), & minimum clearances, (Section 2.4) are satisfied.

These minimum clearances are essential to provide access for

servicing, and are included on the wall mounting template.

a)

Take the template (Fig. 13) and tape the template onto the wall

in the desired position. (Ensuring that the centre line is level).

b)

Mark the position of the six wall mounting bracket fixing holes.

c) REAR OUTLET ONLY:

. If the installation is to use a rear

outlet, mark the position of the air/flue duct hole (from the

template) onto the rear wall.

4.1

UNPACKING THE APPLIANCE

The appliance and standard flue kit is supplied in a single cardboard

carton. In addition various optional flue kits are available as

described in section 2.5. If the appliance is to be installed without

access to the outside wall, a wall liner kit is also required.

Open the carton. Unpack the appliance, flue pack and any

option kits and check the contents against the following lists.

13

WALL MOUNTING TEMPLATE

14

MARKING THE POSITION OF A

SIDE FLUE

d) SIDE OUTLET ONLY:

If the installation is to use a LH or RH

side outlet, mark the position of the centre line of the air/flue

duct hole (from the template) onto the rear wall. Extend this

mark horizontally until reaching the side wall face, then draw

the position of the air/flue duct hole as detailed in Fig. 14.

e) VERTICAL OUTLET ONLY:

Using the wall template and the

dimensional information given in section 2.4 & 2.5. Calculate

where the boiler flue should be positioned and make the

necessary hole(s) in the ceiling/roof. Proceed to (k).

f)

ADDITIONAL ELBOW OR FLANGED DUCT WITH ELBOW:

Using the wall mounting template and the dimensional

information given in section 2.4 & 2.5. Calculate where the

boiler and flue are to be positioned and make the necessary

hole(s) in the wall(s)/ceiling/roof for the air/flue duct.

Proceed to (k).

g)

If the air/flue duct length is to be greater than 2.25m (88 in)

it is necessary to fit at least one support in the middle of the

duct. A support bracket kit is available as an optional extra.

Follow the fitting instructions provided with the bracket before

proceeding further.

h)

Remove the template and check the dimensions between the

centre lines of the flue and fixing holes shown in Fig. 13.

Drill the fixing holes using a 8mm masonry drill. Fit the

plastic plugs provided.

BOILER PACKAGE:

Boiler (Assembled.)

Installation, Servicing

and Users instructions.

Wall mounting template.

Plastic bags containing:

6 x Fixing screws.

Flue Turret Gasket.

2 x Split Pins.

6 x Rawl plugs.

2 x 28mm olives.

4 x screws for Flue turret.

Control knob.

FLUE COMPONENTS:

Inner wall sealing ring.

(white).

Telescopic flue assembly.

Outer wall sealing ring

(grey).

Flue turret elbow.

4 self tapping screws.

60mm dia. ‘O’ ring for

turret (fitted).

Dia ‘A’ Hole diameter 130mm if optional wall liner kit is to be used

for fitting flue/air duct from inside the room.

Dia ‘B’ Hole diameter 100mm if duct to be fitted from outside.

Dia ‘C’ Hole diameter to suit alternative wall liner (supplied by

installer) with an inside diameter between 127mm & 140mm.

OUTSIDE

OF CASING

OUTSIDE

OF WALL

BRACKET

TOP FIXING

HOLES

BOTTOM FIXING

HOLES

BOTTOM OF

APPLIANCE CASING

MINIMUM BOTTOM

CLEARANCE

12mm

12mm

DIA. "A"

DIA."B"

DIA."C"

200mm

95mm

180mm

550mm

100mm

MINIMUM LH SIDE

CLEARANCE 6mm

CENTRE LINE

BOILER FL

UE

MINIMUM RH SIDE

CLEARANCE 6mm

DUCT

CENTRE

LINE

WALL

TEMPLATE

POSITION OF

DUCT HOLE

CORNER OF

WALL

144mm