28

35

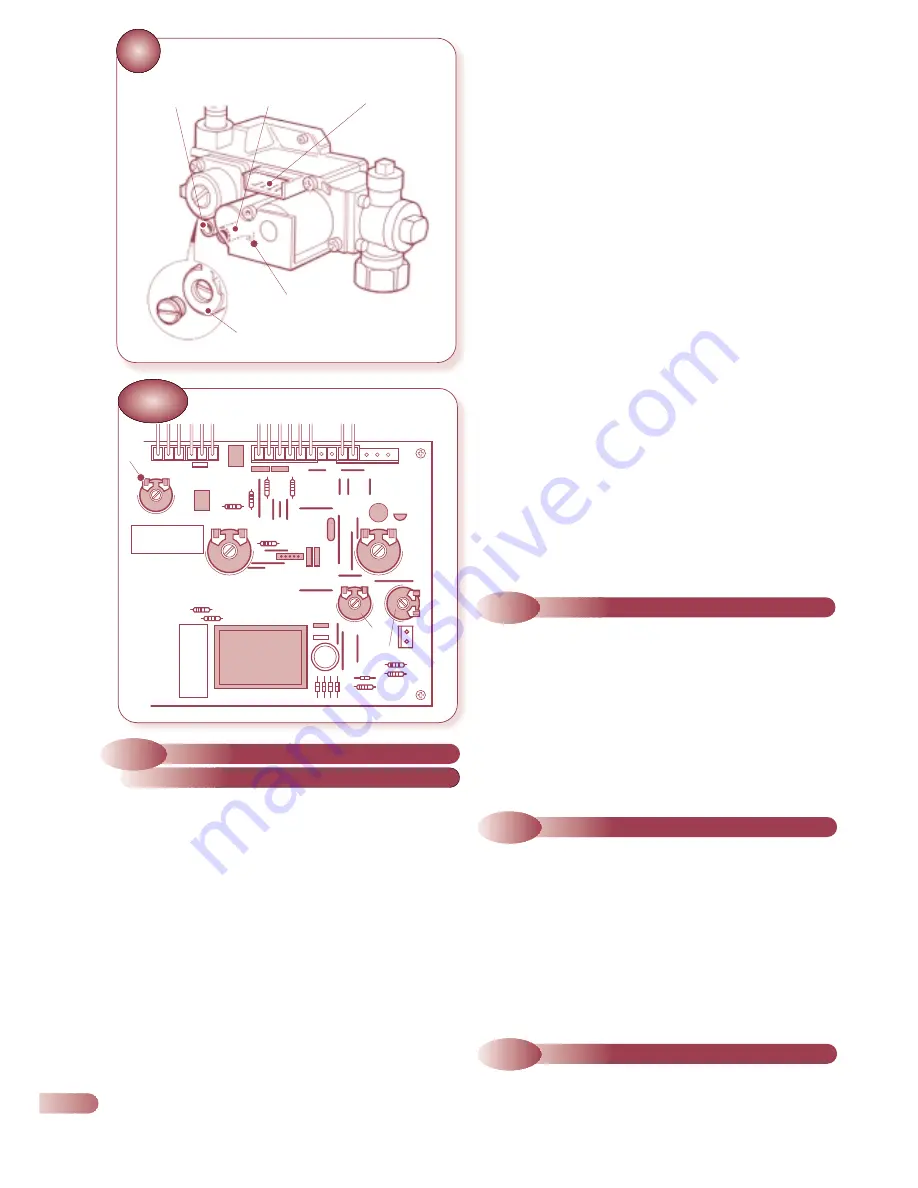

MULTIFUNCTIONAL GAS CONTROL

9.7

AIR PRESSURE SWITCH

9.8

OVERHEAT THERMOSTAT

9.9

PCB

a)

Remove the casing front panel and lower the control fascia

panel as described in section 9.6.1 step (a).

b)

Remove the PCB plastic cover (Fig. 32).

a)

Remove the casing front panel as described in section 9.1 step

(a) and remove the sealed chamber front panel (4 screws).

b)

Disconnect the pressure sensing pipes from the pressure switch

(note that the short pipe (from the flue gas sampling point) is

connected to the rear (-ve) connection on the pressure switch).

c)

Unscrew the two screws securing the pressure switch, and

transfer the electrical connections to the new switch.

d)

Fit the new pressure switch and re-assemble in reverse order

referring to the wiring diagrams (section 7) if necessary.

a)

Remove the casing front panel and lower the controls fascia

panel as described in section 9.6 step (a).

b)

Unclip the thermostat phial from the pipe, and disconnect the

two electrical connections (Fig. 36).

c)

Unscrew the four screws (underneath) securing the appliance

base plate and controls fascia panel. Carefully support the

fascia panel and unscrew the nut securing the overheat

thermostat.

d)

Replace the thermostat and re-assemble in reverse order.

Ensure that the phial is correctly clipped onto the pipe.

g)

Set the minimum gas valve stop by adjusting the small screw

on the gas valve (Fig. 35) until the burner pressure is set to

1.3 mbar.

h)

Maximum Hot Water Heat Input: On the PCB, turn

potentiometer P3 (max CH set point) to its maximum position

(fully anti-clock).

i)

Set the maximum gas valve stop by adjusting the large gas

valve screw (behind the screw cap, Fig, 35) until the burner

pressure is 9.7 mbar.

j)

Minimum CH heat input: Turn the potentiometer P6 until the

burner pressure is set at 2.5 mbar.

k)

The maximum CH heat input may be set at any point between

the minimum and maximum gas control setting (originally

factory set at 6.3 mbar). This can be adjusted with the

potentiometer P3.

l)

Isolate the appliance and remove the link between pins 1 and

2 on terminal X4A. Switch the appliance back on at the mains

isolation switch.

m)

Check that the pressures are correctly set by turning on and off

the DHW tap several times and on each occasion allowing the

burner to ignite.

n)

Reduce the DHW draw off rate progressivley and check that the

burner pressure reduces in response to DHW temperature rise.

o)

Close the DHW tap and ensure that the burner is extinguished

and the pump stops (after a brief overrun period). Remove the

pressure gauge, open the DHW tap to re-light the burner and

test for gas soundness.

p)

Close the DHW tap, re-seal the adjusted potentiometers, re-

assemble the control panel and casing, then set all boiler

controls as required.

ELECTRICAL

CONNECTOR PLUG

BURNER

PRESSURE

GAS INLET

PRESSURE

a)

Connect a suitable manometer to the gas inlet and burner

pressure test points (see Fig. 35). Turn on the gas supply.

Check for gas soundness taking the precautions described in

section 5 and re-commission the appliance in accordance

with section 5.3. In addition, it will be necessary to set the

heat inputs for hot water.

b)

Remove PCB cover and establish link between pin 1 and 2

on terminal X4A.

c)

Set the Main Switch to the Heating & Water position and the

temperature control knobs to high.

d)

Set the clock to the ON position (I) and ensure any external

controls are calling for heat.

e)

Ignition: Disconnect spark electrodes and open hot water tap

fully. During the 10 second ignition attempt turn the

potentiometer P4 until the burner pressure is approx. 5mbar.

f)

Minimum Hot Water Heat Input: Open a hot water tap fully

and as soon as the appliance has lit turn the potentiometer

P3 (-CH set point) to its minimum (clockwise) position (Fig. 35a).

9.6.2

GAS CONTROL AND PCB BURNER

PRESSURE SETTING PROCEDURE

MAXIMUM GAS

VALVE STOP

MINIMUM GAS

VALVE STOP

35a

PCB SECTION

P3

•

P6

•

P4

Содержание Ace High

Страница 8: ...8 EXPLODED DIAGRAM for key no references see spare parts catalogue Drawing amended 8 6 00 6 ...

Страница 25: ...INTERNAL WIRING DIAGRAMS 7 7 1 FUNCTIONAL FLOW WIRING DIAGRAM 23 ...

Страница 26: ...7 2 ILLUSTRATED WIRING DIAGRAM 24 ...

Страница 40: ...Ace Ace High Wickes Combi 82 102 05 04 ACE ACE HIGH WICKES COMBI 82 102 ...