6. Maintenance

9

Properly maintained, the HAKKO 474 desoldering gun should provide years of good service.

Efficient desoldering depends upon the temperature, and the quality and quantity of the solder and flux. Per-

form the following service procedures as dictated by the conditions of the gun’s usage.

WARNING : Since the desoldering gun can reach a very high temperature, please work carefully.

Except when cleaning the nozzle and heating element, always turn the power switch off and discon-

nect the power plug before performing any maintenance procedure.

Servicing the Desoldering Gun

CAUTION

The desoldering gun will be extremely hot.

During maintenance, please wear gloves and

work carefully.

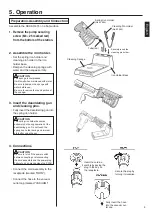

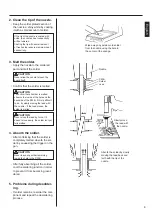

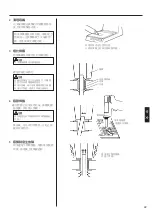

1. Inspect and clean the nozzle.

• Plug in the power cord, turn the

power switch On and let the nozzle

heat up.

• Clean out the hole of the nozzle

with the nozzle cleaning pin.

CAUTION

The cleaning pin will not pass through the

nozzle until the solder inside the nozzle is

completely melted.

• If the cleaning pin does not pass

through the hole in the nozzle,

clean with the cleaning drill.

• Check the condition of the solder

plating on the tip of the nozzle.

• If it is slightly worn, recoat the tip with

fresh solder to prevent oxidation.

• Check the condition of the surface

and inside hole of the nozzle.

• If either is worn or eroded, or the

inside diameter seems unusually

wide, replace the nozzle.

CAUTION

The inside hole and the surface of the

nozzle is plated with a special alloy.

Should this alloy become eroded by high-

temperature solder, the nozzle will not be

able to maintain the proper temperature.

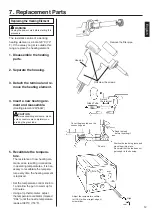

2. Disassemble the heating

element.

CAUTION

The heating element is very hot during

operation.

3. Clean out the hole in the

heating element with the

provided cleaning pin.

CAUTION

Be sure the solder in the hole in the heat-

ing element is completely heated, before

cleaning the hole.

• If the cleaning pin cannot pass

through the hole, replace the heat-

ing element.

• Turn the power off after cleaning.

Cleaning with the nozzle cleaning pin

Cleaning with the cleaning drill

• Before cleaning

• After cleaning

Solder plating

Diameter of hole is wid-

ened through erosion.

(Desoldering Gun)

The cleaning pin passes com-

pletely through the hole.

Insert the bit while turning it clockwise.

Pull the drill bit out straight without turning it.

CAUTION

If the cleaning drill is forced into the nozzle,

the drill bit could break or be damaged.

CAUTION

Please use the proper size cleaning pin or

cleaning drill for the nozzle diameter.

CAUTION

Unfortunately, it is often difficult to observe

this condition. Therefore, if desoldering

efficiency goes down and all other parts

appear to be OK, the nozzle is probably

eroded and should be replaced.

Heating Element

Element Cover

Nozzle

Nut

Remove the nut with the attached wrench.

Scrape away all oxidation from the hole in the heating element until the

cleaning pin passes cleanly through the hole.

The cleaning pin passes cleanly

and completely through the hole.

English

Содержание 474

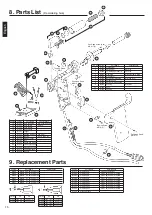

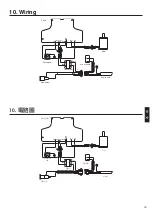

Страница 19: ...3 18 1 2 M4 25 380 480 HAKKO...

Страница 20: ...4 19 29 30 31 A1033 23 21 21 A1009 100V 110V 125V 2A 120V 250V 2A U 220V 230V 250V 1A 240V 250V 1A S...

Страница 21: ...20 5 B1094 B1095 HAKKO 474 1 M4 25 2 3 4 IRON VACUUM...

Страница 22: ...21 1 2 1 2 5 6 3 5 3 1 HAKKO 191 HAKKO 192 HAKKO 474 380 480 1 2 3 4 5 6...

Страница 23: ...22 2 3 4 5...

Страница 24: ...23 1 HAKKO 475 HAKKO 475 HAKKO 475 2 1 3 3 2 1 A B A 70 80 25 25 5 25...

Страница 25: ...24 HAKKO 474 B 25_26 20 25 26 24 20 28 a b c d e f...

Страница 26: ...6 25 HAKKO 474 1 2 3...

Страница 27: ...26 6 A1033 A1033 4 A1033 5...

Страница 28: ...27 1 A1009 2 1 2 3 A1009 S20 6 VACUUM...

Страница 29: ...28 7 23 2 4 1 2 3 4 24V 50W 5 1 3 CAL 380 CAL...