HAKKI PILKE RAVEN

TRANSLATION

VERSION 1-2015

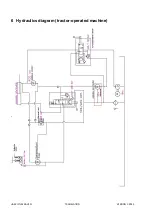

4.11 PRESSURE REGULATING VALVES

The pressure regulating valves are adjusted to the correct settings at the factory. The firewood processor's

guarantee is voided if the factory adjustments are changed. If you need to change the adjustments, first

contact the manufacturer or retailer and follow their instructions carefully. Changing the cartridge settings

incorrectly may damage the machine or render it hazardous to operate. The relief valve adjustments can be

changed as follows: loosen the locking nut (or remove the protective cup) and rotate the hex socket screw

clockwise or anti-clockwise (when turning the screw clockwise, the pressure increases and vice versa). Fi-

nally, tighten the locking screw. The locations of the relief valves are indicated in the following figures.

1.

Cutting and splitting valve pressure regulating screw (200 bars) in Figure 48.

2.

Relief valve pressure regulating screw (80 bars) in Figure 49.

3.

Output conveyor relief valve (100 bars) in Figure 51.

4.

Sequence valve pressure regulating screw (40 bars) in Figure 50.

Figure 48.

Figure 49.

Figure 50.

Figure 51.