22

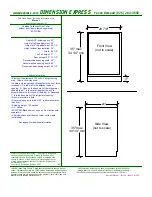

CIRCUIT DIAGRAM

Display diagram

Haier Group

Design

Auditing

Approval

Model

No.

Version

:A

Page

Ye fu CHEN

B

A

C

D

1

2

3

4

D

C

B

A

4

3

2

1

+12

CY100

222/250V

CX100

0.01UF/ 275VAC

E100

22uF/ 450V

RT100

B57237

RV100

S14K350

FUSE100

FUSE-T-3.15/250-5*20

D102

1N4007

D105

1N4007

D104

1N4007

D103

1N4007

C103

103/630V CBB

R100

78K/2W

R104

RT15X-100

E105

10UF/ 50V

E104

4.7UF/400V

IC101

PC817A

D106

ER202

C101

470PF/100V E101

CD263-470uF/ 35V

R102

RT15X-47

R101

RT15X-47

D107

ER202

C102

470PF/100V

E102

1000uF/ 16V

R57

2K

R56

4.7K-1%

L102

20uH/ 1A

C106

104

E103

100uF/16V

IC102

TL431

R109

1K

R108

RT15X-47

R111

10K

C107

104

R113

4.3K-1%

R110

4.7K-1%

+5

C105

104

1

2

3

4

5

6

CN1

1123724-6

N

K1

OMI-SH-112LM

D5

RLS4148

L

K2

G5NB-1A-E

L

L

K3

G5NB-1A-E

N

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

IC1

ULN2003

+12

+12

+12

1

2

3

4

CN2

1123724-4

L

L

D6

RLS4148

D1

1N4007

D2

1N4007

+12

+12

N1

2SC2412K

R9

2K

R1

4.7K

K4

G5NB-1A-E

K5

G5NB-1A-E

L

L

D3

1N4007

D4

1N4007

+12

+12

K6

G5NB-1A-E

K7

G5NB-1A-E

N

L

+12

K8

G5NB-1A-E

+12

R8

2K

R7

2K

R6

2K

R5

2K

R4

2K

R3

2K

R2

2K

MRST

1

PA0/AN0

2

PA1/AN1

3

PA2/AN2

4

PA3/AN3

5

PA4/AN4/T0CKI

6

PA5/AN5/SS

7

VSS

8

OSC1

9

OSC2

10

PC0/T1CK1

11

PC1/CCP2

12

PC2/CCP1

13

PC3/SCK/SCL

14

PC4/SDI/SDA

15

PC5/SDO

16

PC6/TX/CK

17

PC7/RX/DT

18

VSS

19

VDD

20

PB0/INT

21

PB1

22

PB2

23

PB3

24

PB4

25

PB5

26

PB6

27

PB7

28

IC2

HR6P73

+5

1

2

3

4

CN3

5267-4

+5

R16

10K

R20

1K

C5

103

R21

100

R22

100

1

2

3

4

5

6

7

8

9

10

11

12

CN5

440052-12

P2

2SA1037AK

R18

10K

R30

2K

R17

10K

R15

2.4K

C4

104

+5

RST

C1

104

R37

2K

R38

2K

R34

4.7K-1%

R35

4.7K-1%

+5

R36

2K

C2

104

C3

104

R28

2K

R13

4.7K

R14

4.7K

N3

2SC2412K

C8

103

+5

R40

2K

C10

103

D9

RLS4148

+12

D8

RLS4148

C11

104

N4

2SD1781K

R29

4.7K

R43

4.7K

R39

1

+12

D10

RLS4148

C12

104

R41

1

R42

1

+12

D11

RLS4148

C13

104

+12

+12

+12

N5

2SD1781K

R31

4.7K

R44

4.7K

N6

2SD1781K

R32

4.7K

R46

4.7K

R45

000

XT1

4M

1

2

CON1

TJC3-2Y

+5

R23

100

P3

2SA1037AK

R24

10K

R25

4.7K

1

2

3

4

5

CN4

B5B-XH

+5

R26 2K

R10 4.7K

R11

4.7K

N2

2SC2412K

C7

103

+5

R27

2K

C6

103

D7

RLS4148

R12

4.7K

+5

P1

2SA1037AK

R33

2K

R19

10K

C9

103

R49

2K

+5

LED1

Red

LED

R47

4.7K

R48

4.7K

L

CX1

0.01UF/ 275VAC

R50

120/1/2W

L

CX2

0.01UF/ 275VAC

R51

120/1/2W

N

CX3

0.01UF/ 275VAC

R52

120/1/2W

N

D100

UF4007

R115

390K

1

2

CN6

5267-2A

+5

C14

104

J1

J10

+12

+12

C15

103

J2

J10

E1

100uF/16V

J3

J10

+5

+5

J4

J7.5

J5

J7.5

+12

+12

C16

103

J6

J12. 5

J7

J10

+12

+12

J8

J10

R53

000

C17

104

R55

000

Up sensor

Down sensor

Door switch

LED

Lamp

Up fan

Down fan

Sensor 1

(

Prepared

)

PWM

(

Prepared

)

Display panel interface

Internet interface

Down vavle

Up vavle

Prepared

N

N

Down

HTR

Up

HTR

Compressor

L

N

12V 5% 450mA

5V 1% 500mA

ZD4

5.6V

N

L

L100

2.2mH/1A

1

10

9

5

8

T100

BP/M

2

S

6

D

4

EN/UV

1

S

5

S

7

S

8

IC100

TNY276P

L101

20uH/ 1A

E106

220uF/25V

R114

220K

+5

+12

R116

000

R54

000

+5

+5

D12

RLS4148

D13

RLS4148

D14

RLS4148

+5

C18

104

Содержание JC 160GDD

Страница 7: ...6 PARTS IDENTIFICATION ...

Страница 10: ...9 PARTS IDENTIFICATION Net Dimension Model JC 160GDD Unit Dimension W D H 506 595 1280 ...

Страница 22: ...21 CIRCUIT DIAGRAM Circuit Diagram JC 110 160GDD 1 2 ...

Страница 30: ...29 TROUBLE SHOOTING Compressor doesn t start ...

Страница 32: ......