20

WARNING

In the heating mode, since the unit will attenuate with the decrease of the ambient temperature, in the

area where the outdoor outdoor ambient temperature is at the end of the winter, the user is strongly

required to add an auxiliary electric heater on the hot water side, otherwise the user's use effect will be

affected.

■

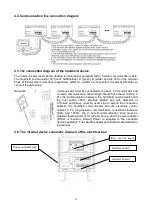

Pump operation control

In order to ensure the normal operation of the unit, it is necessary to use the pump and unit linkage

control. The chilled water pump linkage control contact is provided in the unit control cabinet (only 220V

output control signal is provided, and the pump control part is provided by the user). When the unit is in

the standby state, the water pump does not start. When the standby state enters the working state, the

water pump is started first, and when the machine is switched from the working state to the standby state

or when the machine is shut down, the water pump is automatically stopped after the operation is

completed.

The choice of pump should meet the requirements of the unit: the water flow and the nominal value

of the nameplate should not exceed ± 30%.

■

End linkage control

Pass the passive normally open contact of the end controller (open when the end is not activated

and closed when the end is started) to the main module linkage contact (LINE, OV). When the unit is in

the power-on state, when at least one end is started, the unit starts automatically. When all the ends are

closed, the unit delay automatically turns off. If the unit does not use the end linkage control, LINE and

OV should be shorted.

■

Overload protection control

In the unit control cabinet, the pump overload protection control contact and the auxiliary electric

heating overload protection control contact are provided (only 220V output control signal is provided,

and the passive thermal relay for overload protection is provided by the user). The normally closed

contact of the passive thermal relay is connected to the overload protection control contact. When the

current is too large, the thermal relay protection is disconnected, and the unit alarm stops. If the unit

does not use overload protection control, the overload protection control contact should be shorted.

Note: air conditioning side pump overload control contact (OV-P1, N), hot water side pump overload

control contact (OV-P2, N), air conditioning side auxiliary electric heating overload control contact

(OV-H1, N), hot water side Auxiliary electric heating overload control contacts (OV-H2, N).

4.3 Other

■

Electrical parameter

Unit Type

Rated current

Maximum current

Starting current

Reference cable cross section

CA0065EANR

32A

60A

15A

5X10mm

Note: The working voltage of the unit must be within ±10% of the rated working voltage. If the wiring

distance of the power supply line is too long, the power cable diameter should be increased. It is

recommended to refer to the technical information of the cable manufacturer under the guidance of a

professional electrician.

■

DIP switch definition description and address setting

◆

BM1 DIP switch definition description

model

BM1

DIP1

DIP2

DIP3

DIP4

DIP5

DIP6

DIP7

DIP8

Module address setting

Single

cold / heat

pump

Model setting

Refrigerant

selection

R22/ R410A

CA0065EANR

/

/

/

/

OFF

OFF

OFF

OFF

The first four digits of the BM1 eight-digit DIP switch are set for the module address. The first four digits

of the dialing code are all OFF. The module can only have one host in the system, and the address of

each module can not be the same (1st ~ 4 bits are selected for the module machine address):

Содержание CA0065EANR

Страница 8: ...5 1 2 Main components of the unit ...

Страница 15: ...12 Installation 3 Diagram of arrangement of multiple chiller units Unit mm ...

Страница 26: ...23 Compressor drive module Capacitor plate Lightning protection board Refrigerant heat sink Reactance ...

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......