- 9 -

6.1 Daily maintenance

- General cleaning of the machine to remove

accumulated shavings.

- Clean the lubricating coolant drain hole to avoid

excess fluid.

- Top off the level of lubricating coolant.

- Check blade for wear.

- Rise of saw frame to top position and partial

slackening of the blade to avoid useless yield stress.

- Check functionality of the shields and emergency

stops.

6.2 Weekly maintenance

- Thorough cleaning of the machine to remove

shavings, especially from the lubricant fluid tank.

- Removal of pump from its housing, cleaning of the

suction filter and suction zone.

- Clean the filter of the pump suction head and the

suction area.

- Use compressed air to clean the blade guides (guide

bearings and drain hole of the lubricating cooling).

- Cleaning flywheel housings and blade sliding

surfaces on flywheels.

6.3 Monthly maintenance

- Check the tightening of the motor flywheel screws.

- Check that the blade guide bearings on the heads are

perfect running condition.

- Check the tightening of the screws

of the gear motor,

pump, and accident protection guarding.

6.4 Six-monthly maintenance

- Continuity

test

of

the

equipotential

protection

circuit.

6.5 Maintenance of other machine parts

The

worm

drive

gearbox mounted

on

the

machine

is

maintenance-free

guaranteed

by

its

manufacture.

6.6 Oils for lubricating coolant

Considering the vast range of products on the market,

the user can choose the one most suited to their own

requirements, using as reference the type SHELL

LUTEM OIL ECO. THE MINIMUM PERCENTAGE

OF OIL DILUTED IN

WATER IS 8 - 10 %.

6.7 Oil disposal

The

disposal

of

these

products

is

controlled

by

strict

regulations.

Please

see

the

Chapter

on

"Machine

dimensions Transport - Installation"

in

the

section

on

Dismantling.

6.8 The gear box

The gear box requires periodic changing of oil. The

oil must be changed by the first 6 months of a new

machine and every year thereafter.

To change the gear box oil

- Disconnect the machine from the power source.

- Raise the saw arm to vertical position.

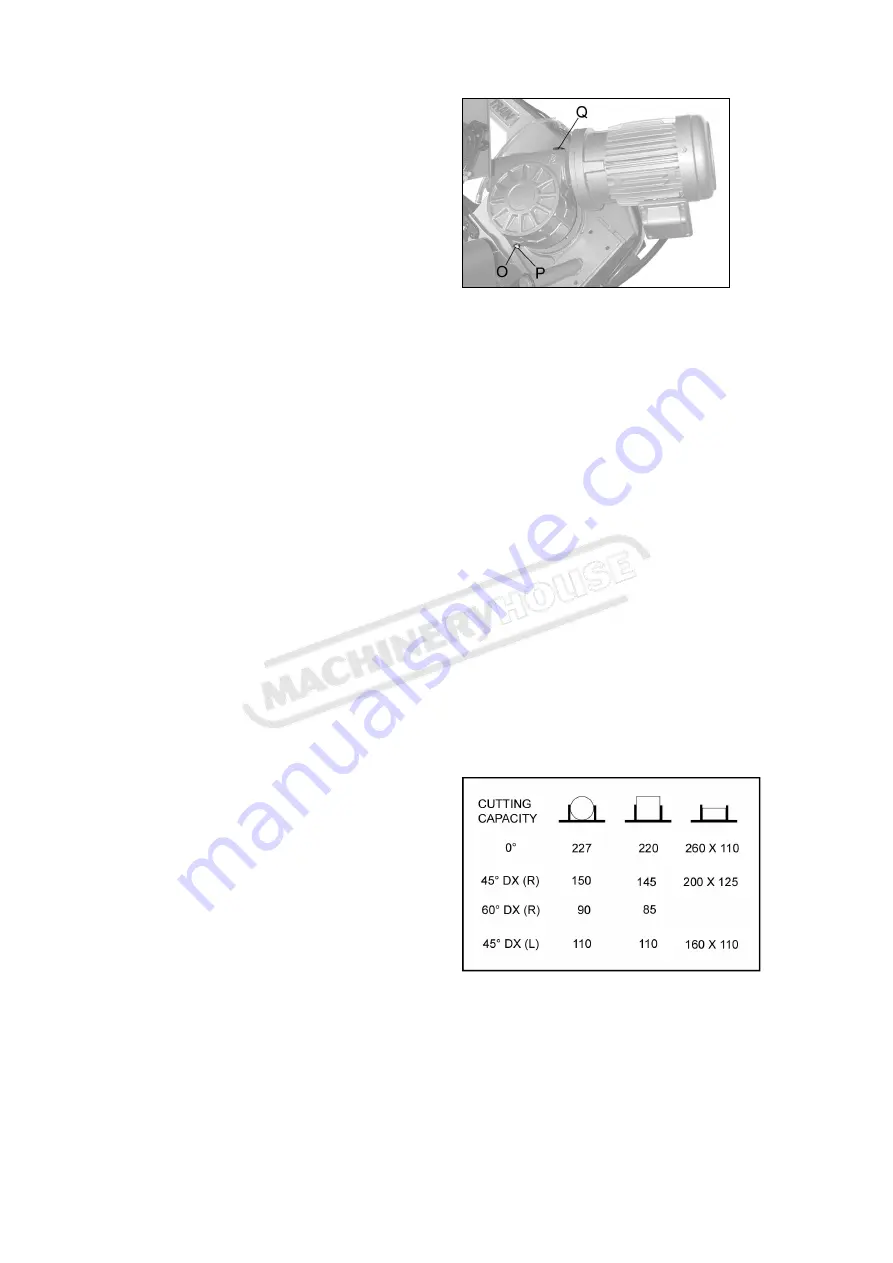

- Release the drain hold (O) to draw off gear oil by

loosening the hex socket screw (P).

- Replace the screw (P) after oil completely flows off.

- Place the saw arm back to horizontal position.

- Fill Gear box with approximately .3 liter of gear oil

through the hole of the vent screw (Q)

For reference, use SHELL type gear oil or Mobile gear

oil #90.

6.9 Special maintenance

Special

maintenance

must

be

conducted

by

skilled

personnel.

We

advise

contacting your nearest dealer

and/or

importer.

Also

the

reset

of

protective

and

safety

equipment

and

devices (of

the

reducer), the

motor,

the

motor pump,

and

other

electrical

components

requires

special maintenance.

7

TECHNICAL CHARACTERISTICS

7.1 Table of cutting capacity and technical details

10

Instruction Manual for EB-270DSA (B066)

31/03/2016

Содержание EB-270DSA

Страница 14: ... 13 10 WIRING DIAGRAMS 14 Instruction Manual for EB 270DSA B066 31 03 2016 ...

Страница 15: ... 14 15 Instruction Manual for EB 270DSA B066 31 03 2016 ...

Страница 25: ... 24 25 Instruction Manual for EB 270DSA B066 31 03 2016 ...

Страница 26: ... 25 26 Instruction Manual for EB 270DSA B066 31 03 2016 ...

Страница 27: ... 26 27 Instruction Manual for EB 270DSA B066 31 03 2016 ...

Страница 28: ... 27 28 Instruction Manual for EB 270DSA B066 31 03 2016 ...

Страница 29: ... 28 29 Instruction Manual for EB 270DSA B066 31 03 2016 ...