18

OPERATION MANUAL

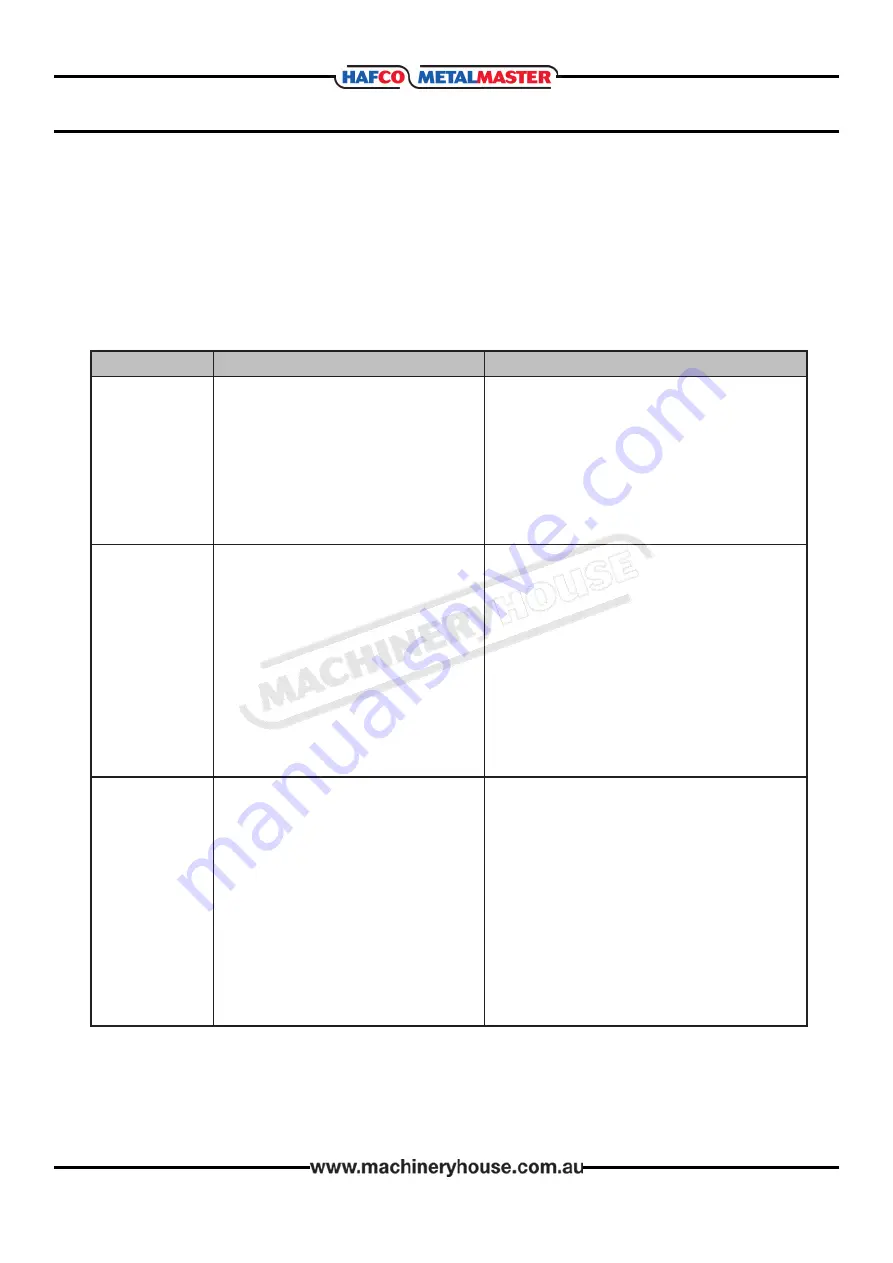

6.5 TROUBLESHOOTING

Review the troubleshooting and procedures in this section if a problem develops with your

machine. If you need replacement parts then follow the procedure in beginning of the spare

parts section or if additional help with a procedure is required, then contact you distributor.

Note:

Make sure you have the model of the machine, serial number,and manufacture date

before calling.

Symptoms

Possible Cause

Possible Solution

Machine does

not start or a

breaker trips.

1. Power supply circuit breaker tripped or fuse

blown.

2. Motor wires connected incorrectly.

3. Plug/receptacle at fault/wired incorrectly.

4. Wiring open/has high resistance.

5. START/STOP or circuit breaker switch at

fault.

6. Start capacitor at fault.

7. Centrifugal switch/contact points at fault.

8. Motor at fault.

1. Ensure circuit is sized correctly and free of shorts.

Reset circuit breaker or replace fuse.

2. Correct motor wiring connections.

3. Test for good contacts; correct the wiring.

4. Check/fix broken, disconnected, or corroded wires.

5. Replace switch/circuit breaker.

6. Test/replace.

7. Adjust/replace centrifugal switch/contact points.

8. Test/repair/replace.

Machine has

vibration or noisy

operation.

1. Debris caught in impeller.

2. Motor or component loose.

3. Motor fan rubbing on cover.

4. Motor mount loose/broken.

5. Motor bearings at fault.

6. Motor shaft bent.

7. Dust collector not on a flat surface.

8. Impeller damaged or unbalanced.

9. Impeller loose on motor shaft.

1. Inspect impeller for debris or damage.

2. Inspect/replace damaged bolts/nuts, and re-tighten

with thread-locking fluid.

3. Fix/replace fan cover; replace loose/damaged fan.

4. Tighten/replace.

5. Test by rotating shaft; rotational grinding/loose

shaft requires bearing replacement.

6. Test with dial indicator. Replace motor if damaged.

7. Stabilize dust collector.

8. Disconnect dust collector from power. Inspect

impeller for dents, bends, or loose fins. Replace

impeller if damaged.

9. Secure impeller; replace motor and impeller as a

set if motor shaft and impeller hub are damaged

Dust collector

does not

adequately

collect dust or

chips; poor

performance.

1. Collection drawer or air filter dust tray are

full.

2. Filters are dirty/clogged.

3. Clog in ducting.

4. Leak in ducting/connections.

5. Ducting blocked/restricted.

6. The dust collector is too far away from the

point of suction, or there are too many

sharp bends in the ducting.

7. Dust collector is undersized.

8. Run capacitor at fault.

9. Centrifugal switch/contact points at fault.

1. Empty collection drawer and dust tray.

2. Clean filters; replace with new filters if performance

does not improve.

3. Remove clog.

4. Seal leak.

5. Remove ducting from dust collector inlet and

unblock the restriction.

6. Relocate the dust collector closer to the point of

suction; remove sharp bends in ducting.

7. Install a larger dust collector.

8. Test/replace.

9. Adjust/replace centrifugal switch/contact points if

available.

Содержание DCM-202

Страница 20: ...20 OPERATION MANUAL SPARE PARTS DIAGRAM ...