26

5

Malfunctions

Malfunction

Possible cause

Remedy

Shearing-off of the

overload protection

The pulling force is too great

Replace the shearing pin*,

reduce the load, or use rope

pulleys

Rope is jammed in the

machine

The rope is damaged or bent,

back-up at the clamping jaws

(formation of baskets)

An incorrect rope is being used

The exit is blocked

Replace the rope or send the

machine to Habegger or an

authorized workshop to be

repaired

Use an original Habegger rope

∅

according to the type plate

Make sure the exit is free

The rope is not being

transported; it only moves

back and forth

Either the rope is worn or an

inappropriate rope is being used

Replace rope or use an original

Habegger rope

Fault

The machine is dirty,

there is a foreign body inside

Dismantle the machine (housing),

clean and oil

Housing is bent or broken

It was not possible for the

machine to adjust itself in the

direction of pull.

Send the machine to Habegger or

an authorized workshop to be

repaired

Anchoring bolt or housing

is bent

The anchoring bolt was not

pushed through correctly or it was

not secured correctly

Send the machine to Habegger or

an authorized workshop to be

repaired

Tow hook is bent open

Incorrect load

Replace the tow hook

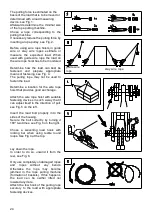

* Replacing a shear pin

If necessary, lower the load until the shear pin is outside

the housing, see Fig. 8. Unlock and remove telescope lever

by turning it.

The broken pieces of the pin can be removed from the

holes with a punch and hammer.

Remove spare pin from the jaw-opening lever (HIT 6/10) or

the carrying grip (HIT 16/32).

Align the holes for the lever parts and beat in the new shear

pin.

Danger! Use only original Habegger brass shear pins.

Shear pins with higher strength can cause the rope pulling machine to be

overloaded and break.

8