EN

27

User manual

WF 35

Translation of the original

instructions

When using red or blue sheathing (for aluminium welding), it is recommended to use the accessory 90950 (I-C). This

stainless steel sheath guide improves the centering of the sheath and facilitates the flow of the wire.

Video

SEMI-AUTOMATIC WELDING IN CUSI AND CUAL (BRAZING MODE)

The unit can weld Ø 0.8 and 1.0 mm CuSi and CuAl wire.

In the same way as with steel, a capillary tube must be set up and a torch with a steel sheath must be used. For brazing, pure argon (Ar) should be

used.

SEMI-AUTOMATIC WELDING WITH CORED WIRE

The unit can weld flux-cored wire from Ø 0.9 to 1.6mm. The original rollers must be replaced by specific cored wire rollers (available as an optional

extra). Welding flux-cored wire with a standard nozzle can lead to overheating and damage to the torch. Remove the original nozzle from your MIG-

MAG torch.

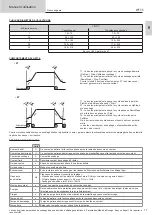

RECOMMENDED COMBINATIONS

(mm)

Current (A)

Ø Wire (mm)

Ø Nozzle (mm)

Flow (L/min)

MIG

0.8-2

20-100

0.8

12

10-12

2-4

100-200

1.0

12-15

12-15

4-8

200-300

1.0/1.2

15-16

15-18

8-15

300-500

1.2/1.6

16

18-25

MAG

0.6-1.5

15-80

0.6

12

8-10

1.5-3

80-150

0.8

12-15

10-12

3-8

150-300

1.0/1.2

15-16

12-15

8-20

300-500

1.2/1.6

16

15-18

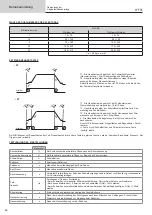

MIG / MAG (GMAW/FCAW) WELDING MODE

Welding processes

Settings

Settings

Manual

Synergies (pre-installed

user settings)

Torque

material/gas

- FeAr 15% CO2

- ...

-

Choice of the material to be welded.

Synergic welding parameters

Wire diameter

Ø 0.6 > Ø 1.6mm

-

Choice of wire diameter

Using the trigger

2T, 4T

Choice of trigger welding management mode

Spot mode

Spot, Spot-Delay

Selecting the spot mode

First Setting

Thickness

Start-up

Speed

-

Choosing the main setting to be displayed (thickness of the workpiece,

average welding current or wire speed).

Access to some of the welding parameters depends on the selected display mode: Settings/Display mode: Easy or Expert. Refer to the HMI ma

-

nual.

WELDING PROCESSES

For more information on GYS pre-installed user settings and welding processes, scan the QR code:

SPOT WELDING MODE

• Spot

This welding mode allows the pre-assembly of parts before welding. Spot welding can be done manually using the trigger or timed with a predefined

spot welding period. Spot welding allows for better reproduction and non-oxidised weld points.