Dokument-No.:2013366

Version a

page

9

Creation date: 28.11.2007

4.

Maintenance

The maintenance work may only be carried out by qualified persons. The maintenance work

consists of:

-

General visual examination

-

Examination of screws

-

Examination of electrical and hydraulic connections

-

Changing of the hydraulic oil

-

Cleaning

Attention!

Before maintenance work can begin the main switch for the power supply must be switched off

and secured against inadvertent activation of the switch.

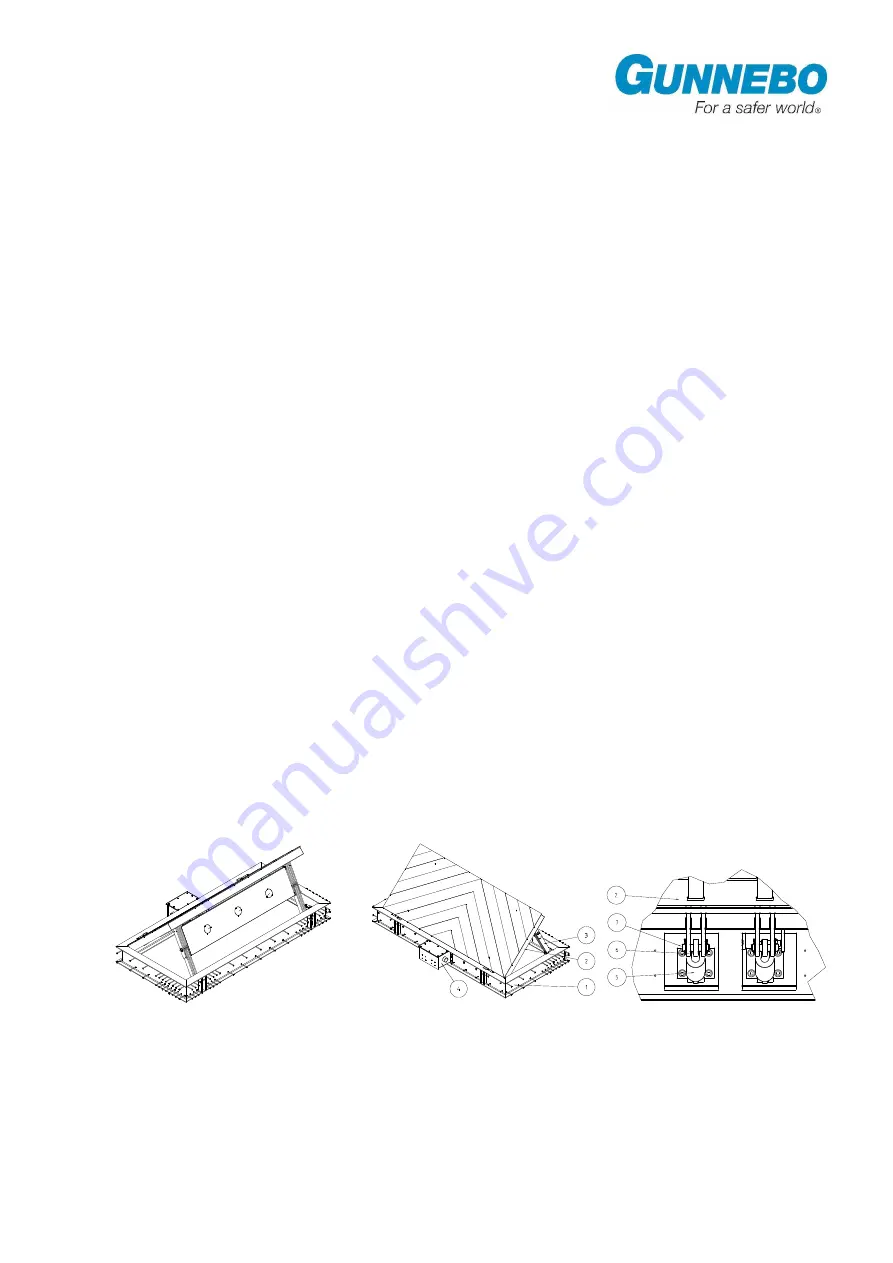

An inspection of the underground housing (1) is possible when the blocking element is in a fully

raised position. It is not necessary to enter the Wedge. In case there is a need for entering the

barrier fix the blocking element in the raised position to prevent any accidents.

The Wedge is an open steel structure. Depending on environmental conditions a more frequent

cleaning of the underground housing may be necessary.

4.1.

Monthly Maintenance

4.1.1. Blocking Element and Underground Housing

(1) Outer visual examination of the entire system for damages, corrosion and deterioration. The

long-term corrosion protection used here includes full galvanisation of all steel components

and a plastic coating of TRI-PROTECT

®

.

Cold-hardening PVC or two-component material is used to repair any damaged areas of the

corrosion protection.

(2) Check the bearings(6), bolts and axle support(7) on the hydraulic cylinders (5) for tightness

and the chain element(3) for any damages.

(3) A tight fit of the proximity switch (8) for the position of the blocking element.

(4) Check the general condition of all functional parts.

(5) Clean the underground housing.

(6) Check the drainage of the housing (1).