4

Band Saw Assembly and Installation

1. The saw may be attached to the worktable or a stand with 6 screws. .

2. The backplate rear end should be mounted on the end of the worktable or the stand so that band

saw can be tilted in the vertical position.

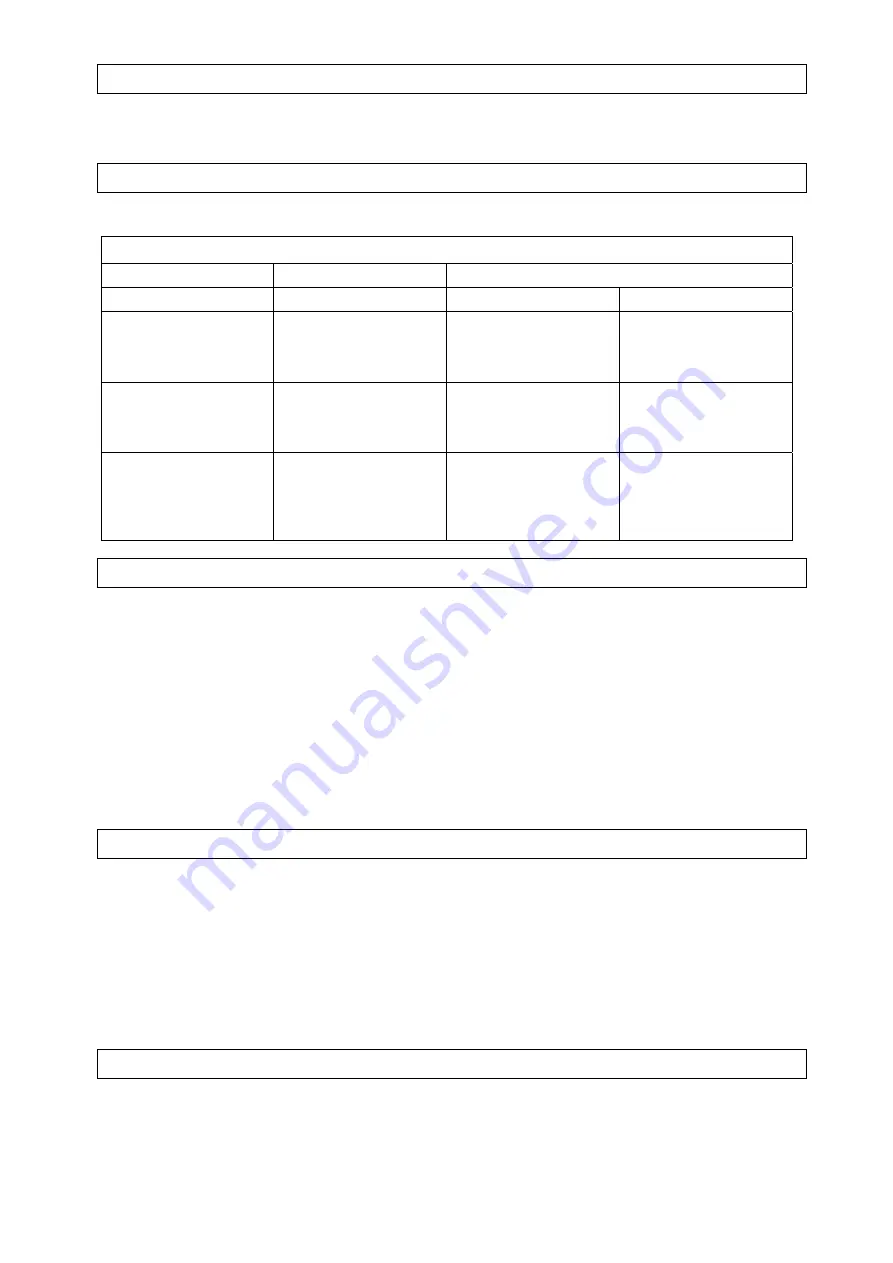

Saw Band Speed

Using the band saw, you should always select the speed most appropriate to the given material. A small

overview of adjusting various materials will give you the list of materials and cutting thereof.

List of Materials and Cutting Thereof

Pulley to be used

Material

Speed

Motor

Saw

Tool steel

Stainless

Bearing bronze

20 m/min.

Small

Large

Regular steel

Hard brass

Bronze

29 m/min.

Medium-sized

Medium-sized

Soft brass

Aluminium

Other light-weight

materials

50 m/min.

Large

Small

Saw Band Replacement

Tilt the saw head into the vertical position, open the band cover and loosen the band clamping screw so

that the band may be removed from the wheels.

Fit in the new band as follows:

1. Put the saw band between the guide bearings.

2. Take the band with your left hand over the drive wheel (down) and hold it in the position.

3. Pull the band up with your right hand to get it closer to the drive wheel.

4. Pull with your left hand further at the saw band upper end

5. Set up the band adjusting screw with your right hand so that it is possible to shift it over the upper

wheel with your left hand.

6. Set up the band tension so that it cannot skid. The tension should not be excessive.

7. Put a couple of oil drops on the band.

8. Close the band cover.

Saw Upper Wheel Alignment

1. Remove the band cover.

2. Loosen the band clamping screw a bit so that the band is not tense at full.

3. Screw the socket screw on the clamping block for the upper wheel to be at precise parallel with the

drive wheel and the band is straight.

4. Put the band in correct tension.

5. Check on the band run so that you will switch the machine on .If the band is skidding forward, the

adjustment should be repeated until the band rear side is in contact with the upper wheel edge.

6. Switch the machine off again.

7. Remount the saw band cover.

Guide Bearings Set-up

Caution:

This is essential adjustment on the saw. . Reasonable result cannot be attained at work, if ht

guide bearing are not set up correctly. Clearance should not be above 0,1 mm or the saw band can be

in contact with the bearing. To set up in this way, the procedure should be as follows:

1. Each bearing should be fitted on an eccentric case and may be adjusted.

Содержание 40536

Страница 8: ...8 Technical Drawing...