22

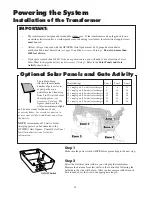

DIP Switches

Main DIP Switch Settings (MODES)

DIP Switch #1 - Soft Start/Stop

The Soft Start/Stop feature slowly starts the gate

as it begins to open and slows the gate as it comes

to the closed position. This saves wear and tear on

the gate and gate opener system.

DIP Switch #2 - Warning Buzzer

The Warning Buzzer alerts you when the gate

opener is beginning to either open or close the

gate. It sounds for the first 2 seconds in each

direction. It also sounds a warning when the gate

obstructs two times in one cycle. Switching this to

OFF only disables the open and close warning not

the obstruction warning.

DIP Switch #3 - Auto-Close

With the Auto-Close switch in the OFF position

the gate will remain open until it receives another

signal from an activation device such as a

transmitter, keypad, or push button control. With

the Auto-Close switch in the ON position the gate

opener will automatically close the gate. The time

the gate will remain open is determined using DIP

Switches #6 and #7.

DIP Switch #4 - Push/Pull-to-Open

If your gate opens into the property the DIP

Switch is set to the OFF position (factory setting).

If your gate opens out from the property the DIP

Switch must be set to the ON position. NOTE: if

you have a Push-to-Open gate application you will

need a Push-to-Open bracket (see Push-to-Open

Instructions on page 30).

DIP Switch #5 - B2/D1 Mode

This DIP Switch must remain in the OFF position

unless the gate opener is going to be used by a

guard or gate attendant, who can only open the

gate when constant pressure is applied to a push

button control device.

DIP Switches #6 and #7

The combination of these two switches determines

the amount of time the gate will remain open

when DIP Switch #3 is set to the ON position.

CONTROL BOARD SETTINGS

1

ON

2

3

4

5

6

7

ON

OFF

1 2 3 4 5 6 7

DIP#6 DIP#7 Delay Time for Auto-Close

ON

ON

15 seconds

ON

OFF

30 seconds

OFF ON

60 seconds

OFF* OFF* 120 seconds (factory preset)

DIP#5

ON

D1 mode, constant pressure to operate gate.

OFF* B2 mode, momentary contact to operate gate.

DIP#4

ON Push-to-open

operation.

OFF* Pull-to-open

operation.

DIP#3

ON Auto-close

enabled.

OFF* Auto-close

disabled.

DIP#2

ON* Buzzer

warning

enabled.

OFF Buzzer

warning

disabled

(for auto-close and soft start/stop only).

DIP#1

ON* Soft

start

enabled.

OFF Soft

start

disabled.

* Factory preset.

GRN

BLK

RED

RECEIVER

COM

COM

CY

CLE

CL

OSE

SAFETY

EXIT

OPEN

SHADOW

L

OOP

CL

OSE

EDGE

OPEN

EDGE

J11

J8

J12

IMPORTANT CONTROL BOARD SETTINGS:

CONTROL BOARD DIP SWITCH #1 is

factory preset in the ON position

and MUST remain in the ON

position. Changing this setting can

damage your gate, gate opener and

possibly void your warranty!