English (GB)

23

• Set the current source to 5.6 mA (this corresponds to 10 %).

This and the following step cannot be done without a current

source.

• Check the dosing flow indicated by the measuring tube.

If this is not 10 %:

Reset the zero point. The floater may reach the end stop if the

dosing flow exceeds 0 %.

• Set the current sensor to 20 mA. Use programming buttons L

and SET to set the servomotor to 100 % dosing flow

(as indicated by the measuring tube). The toothed rack on the

regulating valve must not protrude by more than 31 mm.

Fig. 42

Rate valve with gear rack

• Set the upper limit switch (SL) to a value slightly above 100 %.

• Remount the cover of the servomotor.

6.7.3 Manual operation of the servomotor

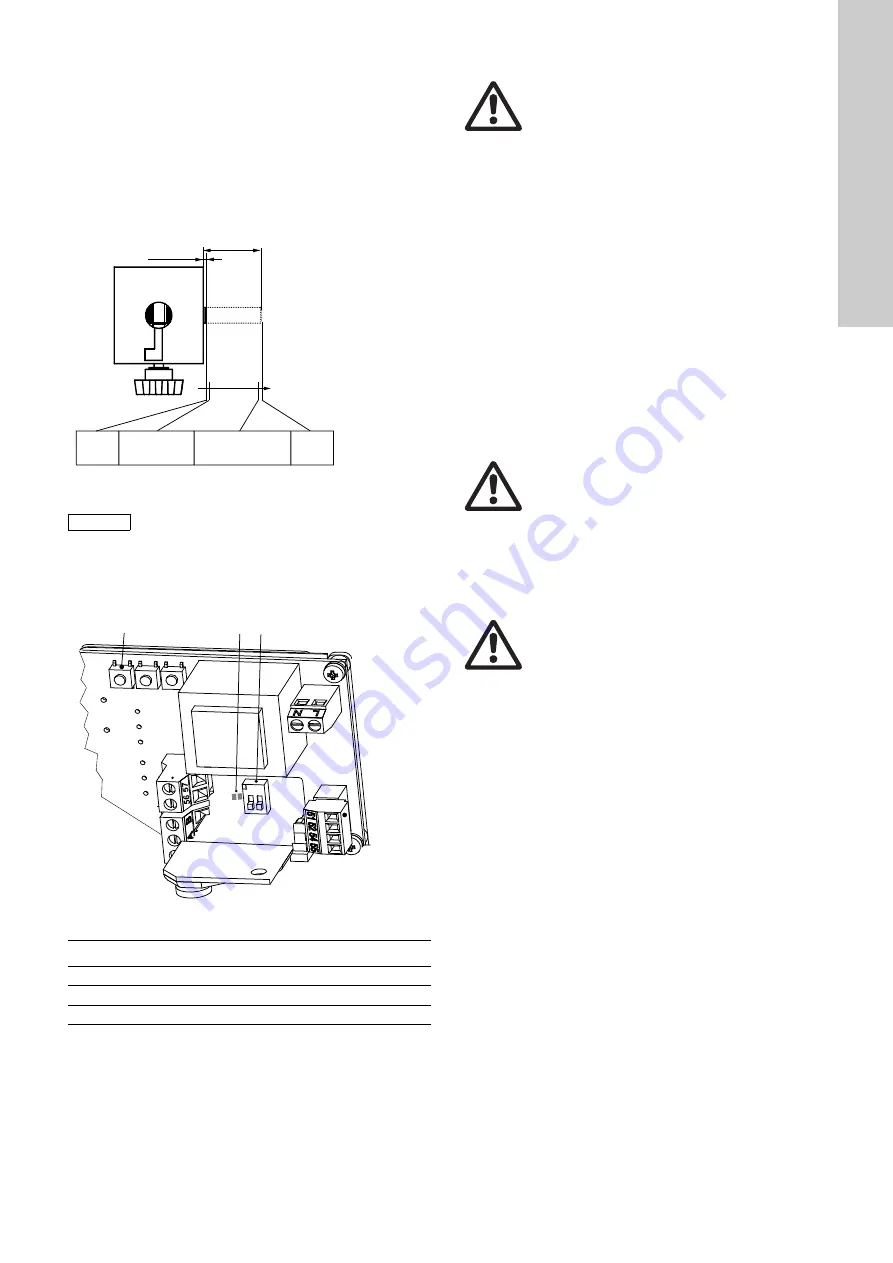

Fig. 43

Servomotor with analogue control

If necessary, the servomotor can also be operated manually.

• Remove the hood from the servomotor.

• Move the switch (item 5, 2) to 'Man'.

• Use programming buttons L or R (item 2) to move the

servomotor to the required position manually.

• Replace the hood on the servomotor.

Switch (item 5, 2) must be reset to 'Auto' for automatic mode.

6.8 Switching on

• Close the rate valve.

• Open the shut-off valve at the injection unit.

• Open the motive water valves.

• Switch on booster pump.

• Open valve of the gas container.

• Slowly open the rate valve until the desired gas flow is

displayed by the measuring tube.

6.9 Switching off

6.9.1 Emergency

• Put on safety equipment!

• Immediately close all container valves.

• Let the plant run until all parts are evacuated from the dosing

medium.

• Switch off the plant as described in the following.

6.9.2 Short-term stop (up to 6 hours)

• Close the rate valve.

• Switch off the booster pump.

• Close the motive water valves.

• Close the shut-off valve at the injection unit.

6.9.3 Long-term stop (while the plant is still running)

• Close all container valves.

• Let the plant run until the measuring tube shows no more gas

flow.

• Close the rate valve.

• Switch off booster pump.

• Close the motive water valves.

• Close the shut-off valve at the injection unit.

TM

04

08

27

09

08

Caution

In case of exceeding: The rate valve may get

damaged!

TM

04

09

60

40

09

Item

Description

2

Programming buttons

4

LEDs

5

DIP switch

31 mm

+0,5

1 mm

+0,5

min.

(ST1)

max.

(ST2)

Ymax

100% = 20 mA

^

Ymin

0% = 4 mA

^

2

5

4

1 2

L

R

SET

on

Warning

Danger!

Do not touch bare wires or clamp screws!

Warning

Immediately leave the room in case of gas break-out

and put on safety equipment!

Then start counter-measures!

Warning

Repairs of components of the system only by

authorized personnel!