3

GROWSPAN

™

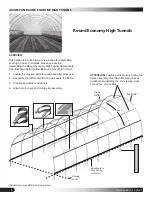

ROUND ECONOMY HIGH TUNNELS

Revision date: 10.25.21

ASSEMBLY PROCEDURE

Following the instructions as presented will help ensure the

proper assembly of your high tunnel. Failing to follow these

steps may result in an improperly assembled and anchored

high tunnel and will void all warranty and protection the

owner is entitled.

The steps outlining the assembly process are as follows:

1. Verify that all parts are included in the shipment. Notify

Customer Service for questions or concerns.

2. Read these instructions, the Must Read document, and

all additional documentation included with the shipment

before

you begin assembling the high tunnel.

3. Gather the tools, bracing, ladders (and lifts), and

assistance needed to assemble the high tunnel.

4. Check the weather

before

you install the roof cover

and any panels (if equipped). Do not install covers or

panels on a windy or stormy day.

5. Re-evaluate the location and site based on the

information and precautions presented in the

documentation included with the shipment.

6. Prepare the site (if applicable).

7. Assemble the frame components in the order they are

presented in these instructions.

8. Assemble the frame including the struts (if equipped).

9. Consult the MUST READ document and properly

anchor the assembled frame.

10. Install, tighten, and secure the end panel and main

cover (if equipped). This applies to fabric covers that

stretch over the frame assembly. Your shelter may

include roof panels or side panels or both.

11. Read the Care and Maintenance information at the end

of these instructions.

12. Complete and return all warranty information as

instructed.

REQUIRED TOOLS

The following list identifies the main tools needed to

assemble the shelter. Additional tools and supports may be

needed depending on the structure, location, and

application.

• Tape measure or measuring device

• Fine point marker to mark the location on tubing.

• Variable speed drill/driver (cordless with

extra batteries works best)

• Wrench, ratchet and socket (recommended)

• Scissors

• Ropes long enough to reach over the frame.

• Hammers and gloves

• Metal file

• Duct tape

• Box cutter or utility knife

• Ladders, work platforms, and other machinery for lifting

designed to work safely at the height of the frame

UNPACK AND IDENTIFY PARTS

The following steps will ensure that you have all the

necessary parts before you begin to assemble the shelter

frame.

1. Unpack the contents of the shipment and place where

you can easily inventory the parts. Refer to the Bill of

Materials/Spec Sheets.

2. Verify that all parts listed on the Bill of Materials/Spec

Sheets are present. If anything is missing or you have

questions, consult the Pictorial Parts Guide and all

diagrams for clarification, or contact Customer Service.

NOTE:

At this time, you do not need to open the plastic

bags containing smaller parts such as fasteners or

washers (if equipped).