Use

only original spare parts and accessories

. The use of other

parts will result in voiding the warranty and the CE marking, and

could cause injury.

The filter head

must be

replaced after 5 years by the

GROHE

service

.

Technical data cooler/carbonator electrical data:

• Connection:

Wall socket with earth wire,

protected via a 10 A fuse

• Voltage supply:

230 V AC / 50 Hz

• Max. power consumption:

180 W

• Type of protection:

IP 21

• Relative air humidity:

max. 75%

• Refrigerant:

0.035 kg - R600a

• Safety shut-off of pump:

approx. 4:30 min

• Operating pressure:

min. 0,2 MPa - max. 1 MPa

• Max. CO

2

inlet pressure:

0.48 MPa

• Max. refrigerant pressure:

3.0 MPa

Sanitary data:

• Cooler/carbonator cooled water capacity:

1.4 l

• Operating pressure:

max. 0.6 MPa

• Flow rate at 0.3 MPa flow pressure:

approx. 2 l/min

• Ambient temperature:

4 – 32 °C

• Temperature

– Cooler/carbonator water inlet:

max. 20 °C

– Cooled water temperature:

approx. 5 – 10 °C

• Sound pressure level LpA (frestanding):

50 ± 4 dB

• Adjustable bypass, factory setting:

2

• Filter capacity:

max. 3000 litres

corresponds to max. 6 months

• Water connection

– Cooler/carbonator:

cold - blue

Electrical test data:

• Software class:

A

• Contamination class:

2

• Rated surge voltage:

2,500 V

The test for electromagnetic compatibility (interference emission

test) was performed at the rated voltage and rated current.

Technical data fitting:

• Flow pressure:

0.2 – 0.9 MPa

• Operating pressure:

max. 1 MPa

• Test pressure:

1.6 MPa

To comply with noise levels if static pressure exceeds 5 bar, a

pressure reducing valve must be fitted.

Avoid major pressure differences between hot and cold water

supply.

• Flow rate at 3 bar flow pressure:

approx. 7 l/min

• Temperature

– Hot water inlet:

max. 70 °C

– Recommended (energy saving):

60 °C

Water connection:

cold - right

hot - left

Thermical disinfektion of the fitting is possible.

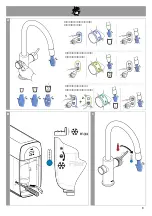

Installation and commissioning

GROHE recommends a depth of min. 510 mm for

the cabinet.

Flush pipes thoroughly before and after installation

(observe EN 806)

!

Adjust bypass of filterhead according to local carbonate

hardness and connect filter cartridge.

The carbonate hardness can be tested by using the enclosed test

strip or the relevant water supplier can provide information on the

carbonate hardness.

The fitting has a system-related run-on time of approx. 1 s.

Note: Make sure that the water inlet hose does not come loose

by movement when installing the cooler.

When transporting or installing the cooler/carbonator,

cooling fluid may have run into the lines.

In order to ensure that the cooling fluid has run back, the

cooler/carbonator may only be installed following a pause

of 24 hours.

Fit CO2 cylinder:

Twist the cylinder until there is a noticeable resistance. To ensure

there are no leaks, after reaching the stop tighten the cylinder by

turning it a further 1/4 of a turn.

Control:

The buttons have the following functions:

Filter replacement reset

Filter size selection and carbontate hardness adjustment

CO

2

-Reset

Display:

In the inactive state, the remaining filter capacity is displayed in per

cent.

When carbonate hardness ≤9° the use of activated carbon

filter (Order no.: 40 547 001) is recommended.

The cooler/carbonator of the GROHE Blue® fitting is set for

operation with the UltraSafe filter cartridge (Prod no.: 40 575 001)

at the factory.

For operation with other filter cartridges the cooler/carbonator must

be set out.

Maintenance and cleaning

CAUTION!

Risk of damage!

Always disconnect the power supply and interrupt the CO

2

supply before carrying out maintenance work on the

system. The plug-in connector can then be disconnected.

Cleaning the cooler/carbonator

For hygienic and health reasons, the cooler/carbonator must be

cleaned once a year. Cleaning must be performed before

changing the filter cartridge, in order to prevent contamination

of the replacement filter cartridge.

Note: The cleaning kit

(Prod. no.: 40 434 001) and the

accompanying adapter (Prod. no.: 40 694 000) are available at

Grohe Authorised Dealers.

20

Содержание Blue HOME 31 606

Страница 3: ...I 3 11 2 2 x 2 1 5 2 1 2...

Страница 4: ...max 60mm max 45mm 1 2 3 8 35 34 6 2 1 7 405 1 4 63 68 5 3...

Страница 5: ...I 19mm 19mm 12 19mm 11 13mm 2 1 9 2 min 11mm 3 1 10 4...

Страница 6: ...I 17 18 1 2 16 15 5 19mm 14 13...

Страница 7: ...I 22 21 1 2 3 6 h 4 5 6 1 2 20 2 min 19...

Страница 9: ...I A 2 1 B C 8...

Страница 10: ...I E8 1 2 11 2 2 x 3 UltraSafe 40 575 001 1 5 2 4 5 4 5 l 6 7 8 9...

Страница 11: ...I EC CO2 1 2 CO2 1 2 3 CO2 4 1 2 3 5 6 7 10...

Страница 12: ...I 1 2 3 4 5 40 434 Xtra Clean 40 694 6 7 11 2 2 x 1 5 2 8 11...

Страница 13: ...I 9 10 11 12 13 40 434 Xtra Clean 11 2 2 x 14 UltraSafe 40 575 001 12...

Страница 14: ...I 1 2 15 16 4 5 l 17 4L 5L 18 19 20 1 2 13...

Страница 15: ...CO2 14...

Страница 16: ...15...

Страница 26: ...25...

Страница 27: ...26...