9

OM-DEES(T)-40(C,A,C2T™) Domestic

JACKET FILLING

The jacket was charged at the factory with the proper amount of treated water.

You may need to restore this water, either because it was lost as venting steam or

by draining. If you are replacing water lost as steam, use distilled water. If you are

replacing treated water that ran out of the jacket, prepare more treated water as

directed in “Water Treatment Procedure,” below.

1. Allow the kettle to cool completely. The procedure will be easier with the kettle

under vacuum (pressure gauge reading below zero).

2. Allow the kettle to cool completely. Remove the pipe plug from the jacket fill

assembly. Pour in the distilled or treated water. Using a funnel will help you

in this process. Hold the pressure relief valve open while you pour, to let air

escape from the jacket. Continue adding water until the water level rises to the

center of the round sight glass.

3. Position a funnel in the opening and fill it with properly treated water.

4. Air that gets into the jacket during the filling operation must be removed,

because it will make heating less efficient. Follow the procedure in Jacket

Vacuum/Removing Air From Jacket above, to restore a negative pressure

reading.

WATER TREATMENT

1. Obtain water treatment compound and a pH test kit from your authorized parts

distributor.

2. Fill a mixing container with the measured amount of water required. (See

table). Distilled water is recommended.

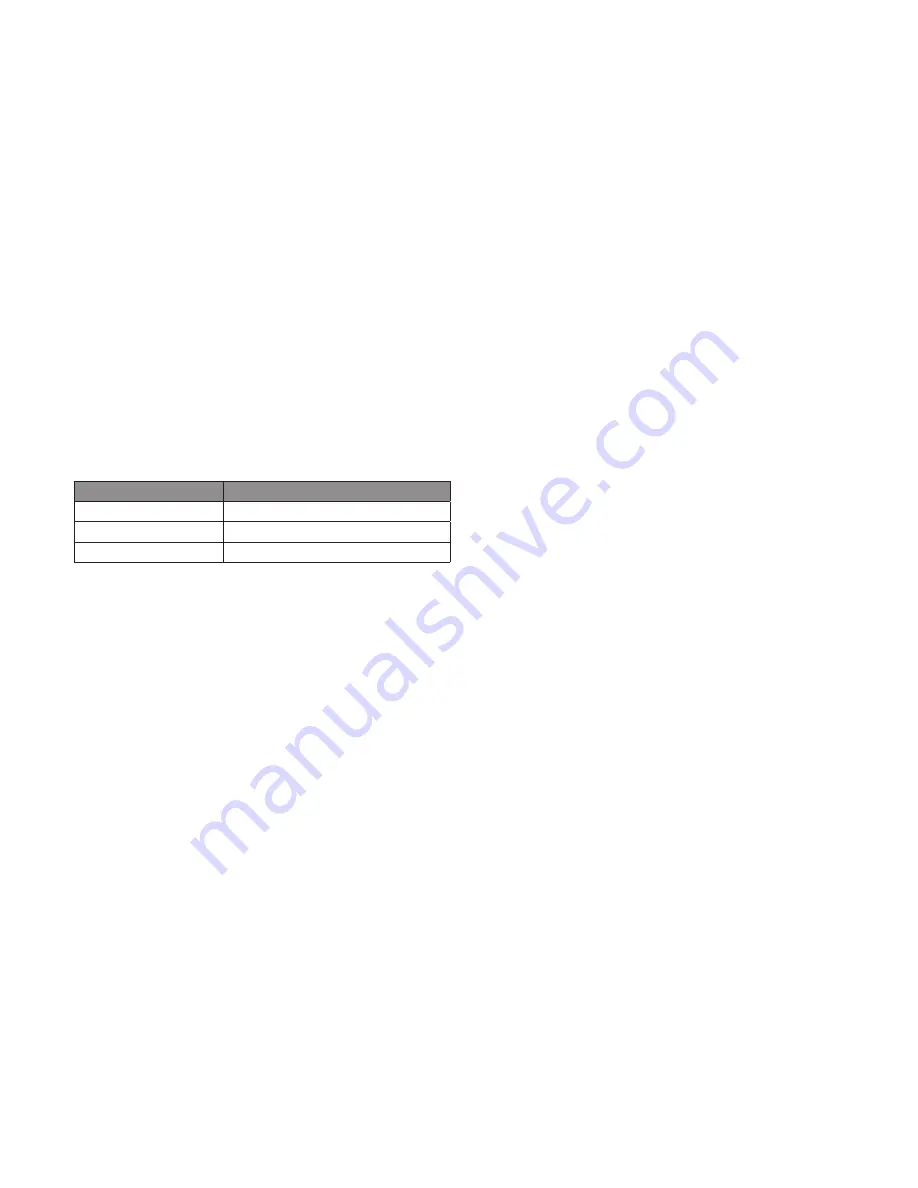

Kettle Model

Jacket Capacity

DEE/4-20(C,A,C2T)

3-1/4 Gallons (12.3 liters)

DEE/4-40(C,A,C2T)

4-1/2 Gallons (17.0 liters)

DEE/4-60(C,A,C2T)

5 Gallons (18.9 liters)

3. Hang a strip of pH test paper on the rim of the container, with about 1 inch of

the strip below the surface of the water.

4. Measure the water treatment compound (One way to do this is to add the

compound from a measuring cup.)

5. Stir the water continuously, while you slowly add water treatment compound,

until the water reaches a pH between 10.5 and 11.5. Judge the pH by

frequently comparing the test strip color with the color chart provided in the pH

test kit. If you are color blind use an electroanalytical instrument to measure

the pH level or have a person who is not color blind read the test strip color

level.

6. Record the exact amounts of water and treatment compound used. These

amounts may be used again, if the same water sources and compound are

used in the future. However, it is best to check the pH each time treated water

is prepared.

SEQUENCE OF OPERATION

The following “action-reaction” outline is provided to help understand how the

kettle works.

When the operator starts up the kettle by turning the power switch “ON” and

heat knob from “OFF” to a desired setting, the control relay closes. This lights up

the heating indicator light and causes the contactors to close, allowing power to

flow to heating elements.

When the temperature of the steam jacket reaches the value corresponding to

the heat setting, the control relay opens. This turns off the heating indicator light

and causes the contactors to open, stopping the power to the heaters.

As soon as the controller senses that the kettle is cooling below the set point, the

control relay closes, the heating indicator light comes on, the contactors close,

and the heaters come on again. On-off cycling continues, keeping the kettle at

the set temperature.

This is why the heating indicator light cycles on and off during normal operation.

Every time the kettle is tilted, the tilt cut-off switch interrupts the power supply to

the heaters, so that the heating elements will not operate while not submerged

in the jacket water.

If steam pressure greater than 50 PSI is generated in the jacket, the safety valve

will open and relieve the excess pressure.

If the jacket water level gets too low before the heating elements overheat, the high-

limit control will open and shut off power to the elements until the kettle cools.

Setting the power switch dial to “OFF” shuts down all control and heating

circuits.

The kettle has the following safety features:

1. Low water cutoff relay that will remove power from control and contactors

until the jacket water level is corrected.

2. High limit pressure switch, set to open at about 46 PSI and to shut down the

heat until jacket pressure is decreased.

3. Pressure relief valve, which will release steam if jacket pressure exceeds 50 PSI.

4. Tilt switch, which shuts off all heat when the kettle is tilted.

REPLACEMENT PARTS

To order parts, contact your Authorized Service Agent. Supply the model

designation, serial number, part description, part number, quantity, and when

applicable, voltage and phase.

CONTACT US

If you have questions pertaining to the content in this manual, contact Unified

Brands at 888-994-7636.

Содержание DEE/4-20 A

Страница 11: ...11 OM DEES T 40 C A C2T Domestic Parts List...

Страница 12: ...12 OM DEES T 40 C A C2T Domestic Parts List...

Страница 14: ...14 OM DEES T 40 C A C2T Domestic Wiring Diagram For Classic Control Models...

Страница 15: ...15 OM DEES T 40 C A C2T Domestic Wiring Diagram For Advanced Cook2Temp Control Models...