Damage to your eyes and lungs could result

from using this machine without proper pro-

tective gear. Always wear safety glasses, a

face shield, and a respirator when operating

this machine.

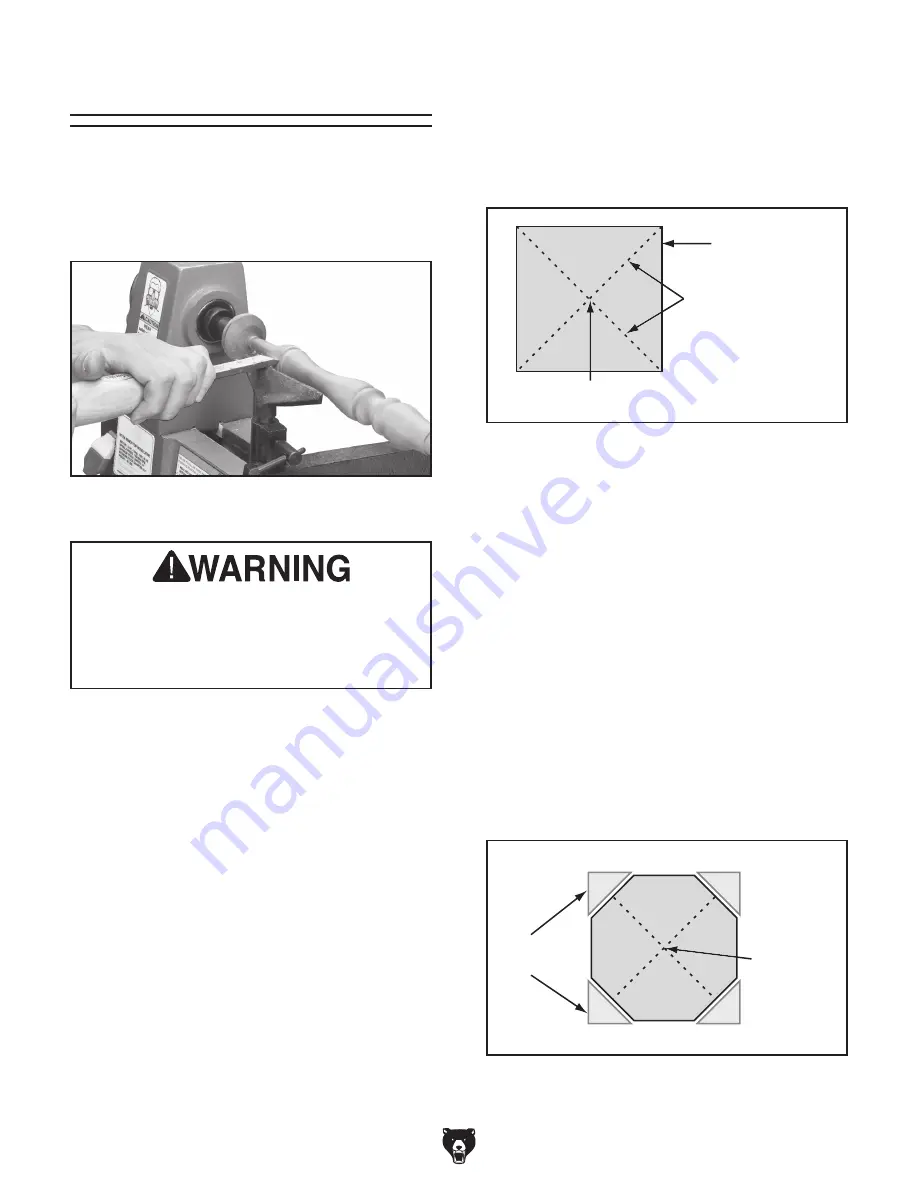

Figure 21. Example of typical spindle turning

operation.

Figure 22. Workpiece marked diagonally from

corner to corner to determine the center.

Workpiece

Workpiece

Center

Pencil Lines

Marked Diagonally

Across Corners

Workpiece

Center

Corners

Removed

Figure 23. Corners of workpiece removed.

-24-

Model T32536 (Mfd. Since 10/20)

Spindle Turning

To set up a spindle turning operation:

1. Find center point of both ends of your

workpiece by drawing diagonal lines from

corner to corner across end of workpiece, as

shown in

Figure 22.

2. Make a center mark by using a wood mallet

and tapping point of spur center into center of

workpiece on both ends.

3. Drill a

1

⁄

4

" deep hole at center mark on end of

the workpiece to be mounted on headstock

spur center.

4. To help embed spur center into workpiece,

cut

1

⁄

8

" deep saw kerfs in headstock end of

workpiece along diagonal lines marked in

Step 1.

5. If your workpiece is over 2" x 2", cut cor-

ners off workpiece lengthwise to make turn-

ing safer and easier when roughing out

workpiece (see

Figure 23).

Spindle turning is the operation performed when

a workpiece is mounted between centers in the

headstock and tailstock, as shown in

Figure 21.

Bowls, table legs, tool handles, and candlesticks

are typical projects where this operation is used.

Tools Needed

Qty

Precision Ruler .................................................. 1

Wood Mallet....................................................... 1

Drill Bit

1

⁄

4

" .......................................................... 1

Tablesaw/Bandsaw ............................................ 1

Содержание T32536

Страница 44: ......