Model T31999 (Mfd. Since 02/20)

-25

-

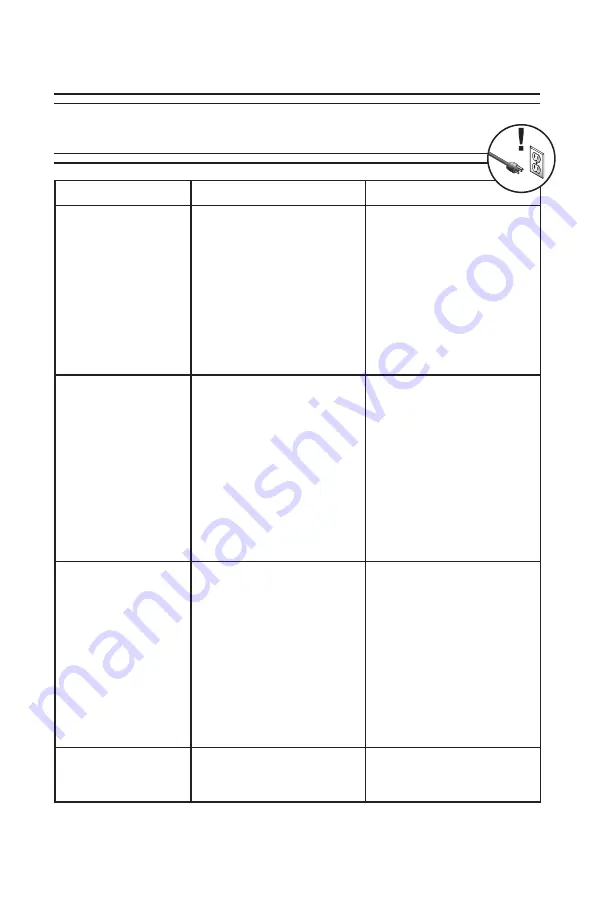

Troubleshooting

SECTION 8: SERVICE

Symptom

Possible Cause

Possible Solution

Tool does not start,

or power-supply fuse/

breaker trips after

startup.

1. Power supply circuit break-

er tripped or fuse blown.

2. Incorrect power supply volt-

age or circuit size.

3. Wiring broken, disconnect-

ed, or corroded.

4. Motor brushes at fault.

5. ON/OFF switch at fault.

6. Motor at fault.

1. Ensure circuit is sized cor-

rectly/free of shorts. Reset

circuit breaker/replace fuse.

2. Ensure correct power sup-

ply voltage and circuit size.

3. Check/fix broken, discon-

nected, or corroded wires.

4. Remove/replace (

Page 24).

5. Replace switch.

6. Test/repair/replace.

Tool stalls or is under-

powered.

1. Workpiece material not suit-

able for tool.

2. Tool undersized for task.

3. Dust bag at fault.

4. Blade at fault.

5. Motor brushes at fault.

6. Motor bearings at fault.

7. Motor overheated.

8. Motor at fault.

1. Only cut wood/ensure mois-

ture is below 20%.

2. Reduce feed rate/depth of

cut.

3. Empty bag/clear dust port.

4. Remove/replace (

Page 20).

5. Remove/replace (

Page 24).

6. Test/repair/replace.

7. Clean motor, let cool, and

reduce workload.

8. Test/repair/replace.

Tool has vibration or

noisy operation.

1. Motor, blade, or component

loose.

2. Blade at fault.

3. Workpiece loose.

4. Motor bearings at fault.

1. Tighten if loose. Replace

damaged or missing bolts/

nuts.

2. Remove/replace (

Page 20).

3. Use the correct holding fix-

ture/re-clamp workpiece.

4. Test by rotating shaft; rota-

tional grinding/loose shaft

requires bearing replace-

ment.

Blade is burning

workpiece.

1. Blade at fault.

1. Remove/replace (

Page 20).

Содержание T31999

Страница 32: ......