-16-

Model T28522 (Mfd. Since 09/18)

Adjusting Setback

Before you begin any bending operation, consider

the differences of sheet metal gauges when try-

ing to achieve either sharp or rounded bends, and

allow for the differences by adjusting the setback.

Setback is the distance from the forward edge

of the fingers to the edge of the bending leaf,

as shown in

Figure 12. The setback distance is

determined by the gauge of the workpiece mate-

rial and the desired radius of the bend.

Setback is normally adjusted 1

1

⁄

2

times the thick-

ness of 22 gauge and thinner workpieces, and

two times the thickness of workpieces thicker than

22 gauge. (Refer to material gauge capacities on

the

Machine Data Sheet on Page 5.)

Figure 12. Determining setback distance for

workpieces 22 gauge and thinner.

Bending

Block

Clamping

Surface

Edge View

A

1

1

/

2

x A

Bending

Leaf

Setback

Distance

Finger

4. Rotate both setback wheels until desired set-

back distance is achieved.

Note: Setback wheels are eccentric. Turning

them one full turn will bring clamping leaf

back to its original position.

Tip: If you find it hard to turn setback wheels

with your fingers, insert a hex wrench into the

holes on edges of wheels to gain leverage.

5. Lower clamping fingers onto clamping sur-

face and check setback distance.

6. If necessary, repeat Steps 1–4 until desired

setback is achieved.

7. Check finger alignment (refer to Aligning

Fingers on Page 15).

You must include the thickness of folded

edges or joints when determining the prop-

er setback, or the brake may be damaged.

Item(s) Needed:

Qty

Hex Wrench 5mm .............................................. 1

To adjust setback:

1. Determine setback required for bend.

2. Raise clamping fingers about

1

⁄

2

" off of clamp-

ing surface.

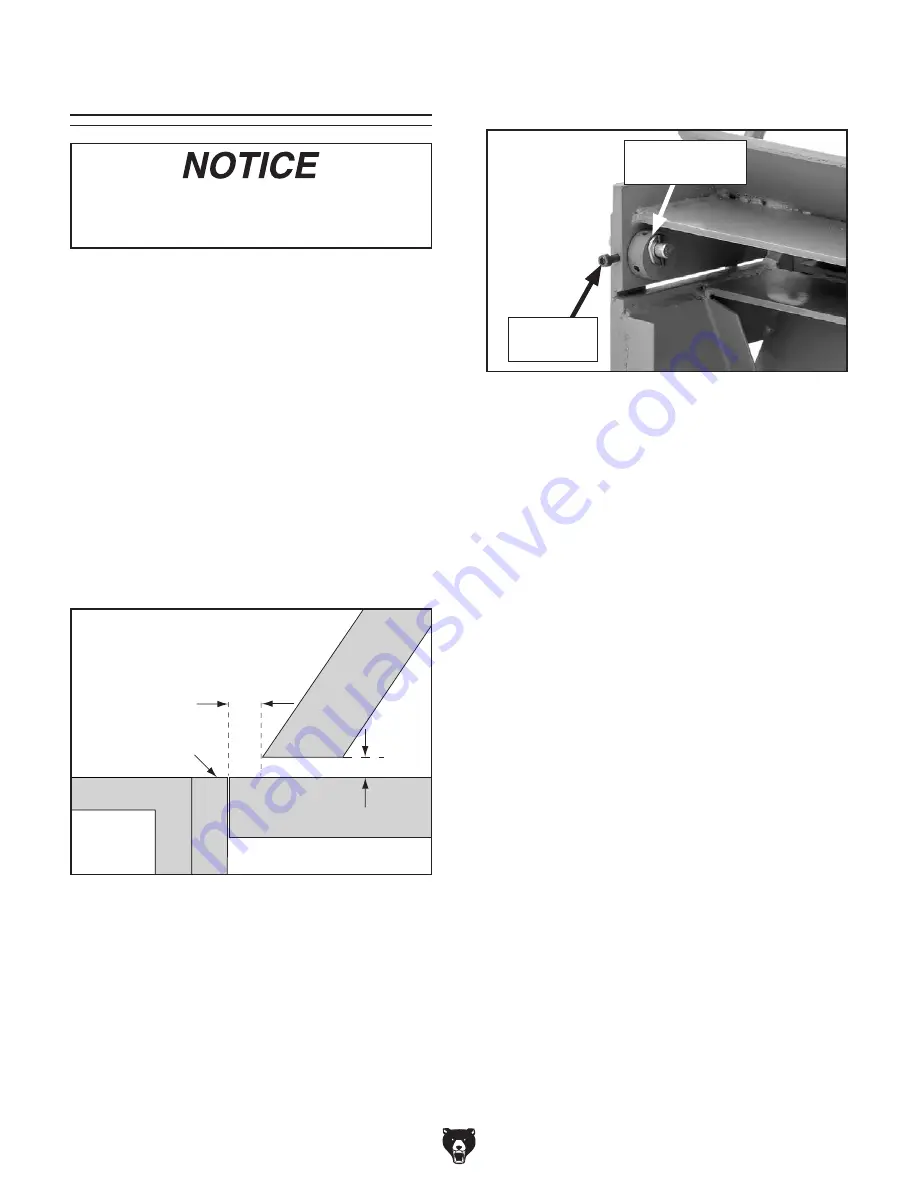

Figure 13. Location of setback wheel and cap

screw.

Cap Screw

(1 of 2)

Setback Wheel

(1 of 2)

3. Loosen cap screws that secure setback

wheels (see

Figure 13).

adjusting setback