Model T10824 (Mfd. Since 07/14)

-21-

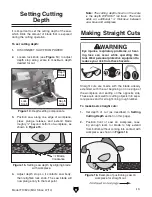

3. Align start cut-point with rear cutting indica-

tor arrow (see

Figure 18). This arrow marks

maximum rear cutting distance blade will

travel when fully extended.

The 24" Rail Track (Model T10825) and Accessory

Pack (Model T27044) are available for purchase

separately through our catalog and on-line.

Using your saw with the rail track allows for quick

and precise cuts with minimal setup time. Both

straight cuts and plunge cuts can be made in con-

junction with the rail track.

Note: The bottom of the rail track includes an

oversized rubber lip that serves as a splinter

guard. The first time the track saw is used with

the rail, the saw blade will cut the edge of that lip

to provide a zero-clearance effect, which will help

minimize splintering.

To set up saw with rail track:

1. DISCONNECT SAW FROM POWER!

2. Place track on workpiece. Orient track so that

your cut-off will be to right of track.

3. When satisfied with position of rail track, use

F-clamps to secure it to workpiece, as shown

in

Figure 19, and place saw onto rail track.

Using Rail Track

Allow the saw to reach full speed before

beginning the cut. Doing so will reduce risk

of kickback, provide better cutting results,

and reduce stress on the motor.

Rear

Arrow

Center

Arrow

Front

Arrow

Figure 18. Cutting indicator arrows.

Note: The front and rear cutting indicator

arrows are only accurate when the blade is

fully extended. If the saw depth gauge is set,

maximum cutting distance will be less.

4. Engage plunge release and lower blade

slightly, but without touching workpiece.

5. To activate saw, engage safety button and

press

ON/OFF trigger while holding plunge

release.

6. Lower blade into workpiece until set cutting

depth is reached. Move saw forward in an

even, steady motion. When front indicator

arrow reaches stop point, the cut has been

completed.

Figure 19. Rail track clamped to workpiece.

Содержание T10824

Страница 32: ......