Model G0803Z (Mfd. Since 12/18)

-53-

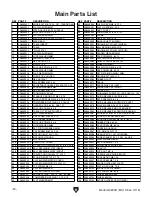

Main Parts List (Cont.)

REF PART #

DESCRIPTION

REF PART #

DESCRIPTION

105

P0803Z105

CAP SCREW M5-.8 X 12

138

P0803Z138

COMPRESSION SPRING 2.5 X 14 X 64

106

P0803Z106

SHOULDER SCREW M5-.8 X 10, 6 X 6

139

P0803Z139

CARRIAGE BOLT M8-1.25 X 80

107

P0803Z107

BALL BEARING 606-2RS

140

P0803Z140

WHEEL ADJUSTMENT BRACKET

108

P0803Z108

CAP SCREW M5-.8 X 16

141

P0803Z141

QUICK-RELEASE PIVOT SHAFT 8 X 90

109

P0803Z109

BLADE GUIDE ROD (LOWER)

142

P0803Z142

EXT RETAINING RING 8MM PUSH-ON

110

P0803Z110

BLADE GUIDE (LOWER)

143

P0803Z143

CAP SCREW M5-.8 X 8

111

P0803Z111

BLADE GUIDE SLIDING COVER (UPPER)

144

P0803Z144

LOCK WASHER 10MM

112

P0803Z112

BLADE GUIDE COVER (UPPER)

145

P0803Z145

WHEEL MOUNT PLATE

113

P0803Z113

DOWEL PIN 3 X 15 W/COMP SPRING

146

P0803Z146

WHEEL SHAFT (UPPER)

114

P0803Z114

BLADE GUIDE DOOR (UPPER)

147

P0803Z147

INT RETAINING RING 26MM

115

P0803Z115

BLADE GUIDE ROD (UPPER)

148

P0803Z148

WHEEL (UPPER)

116

P0803Z116

PHLP HD SCR M4-.7 X 10

149

P0803Z149

BANDSAW TIRE 9-5/16"

117

P0803Z117

BLADE GUIDE (UPPER)

150

P0803Z150

BLADE 62" X 3/8" X 0.025" 10-TPI RAKER

118

P0803Z118

FENCE END CAP

151

P0803Z151

WHEEL COVER (UPPER)

119

P0803Z119

FENCE

152

P0803Z152

BLADE VIEW WINDOW, PLASTIC

120

P0803Z120

CAP SCREW M6-1 X 8

153

P0803Z153

GRIZZLY NAMEPLATE-MINI

121

P0803Z121

FENCE HOLE PLUG

154

P0803Z154

PHLP HD SCR M3-.5 X 6

122

P0803Z122

FENCE SPACER PLATE

155

P0803Z155

LASER SIGHT BOX

123

P0803Z123

FENCE BASE CLIP

156

P0803Z156

LASER SIGHT SWITCH

124

P0803Z124

FENCE BASE

157

P0803Z157

LASER SIGHT

125

P0803Z125

LOCK NUT M6-1

158

P0803Z158

LASER SIGHT BOX COVER

126

P0803Z126

PHLP HD SCR M4-.7 X 6

159

P0803Z159

WHEEL COVER (LOWER)

127

P0803Z127

FENCE POINTER

160

P0803Z160

STANDOFF-SE-ROUND F M5-.8, 17

128

P0803Z128

SET SCREW M6-1 X 8

161

P0803Z161

HEX WRENCH 2MM

129

P0803Z129

CAP SCREW M6-1 X 30

162

P0803Z162

HEX WRENCH 4MM

130

P0803Z130

FENCE HANDLE LOCKING CAM

163

P0803Z163

BEARING SHAFT

131

P0803Z131

FIXED HANDLE 32 X 76, M6-1 X 12

164

P0803Z164

BALL BEARING 696-2RS

135

P0803Z135

SPRING PLATE

165

P0803Z165

EXT RETAINING RING 5MM

136

P0803Z136

PHLP HD SCR M5-.8 X 6

166

P0803Z166

SET SCREW M5-.8 X 5

137

P0803Z137

KNOB M8-1.25, D50, 5-LOBE

167

P0803Z167

HEX NUT M3-.5

Содержание G0803Z

Страница 60: ......