Model G0792 (Mfd. Since 12/15)

-19-

9. When you reach end of bend, release foot

pedal to turn motor

OFF.

10. Repeat Steps 4–9 until you achieve desired

radius (see

Figure 18).

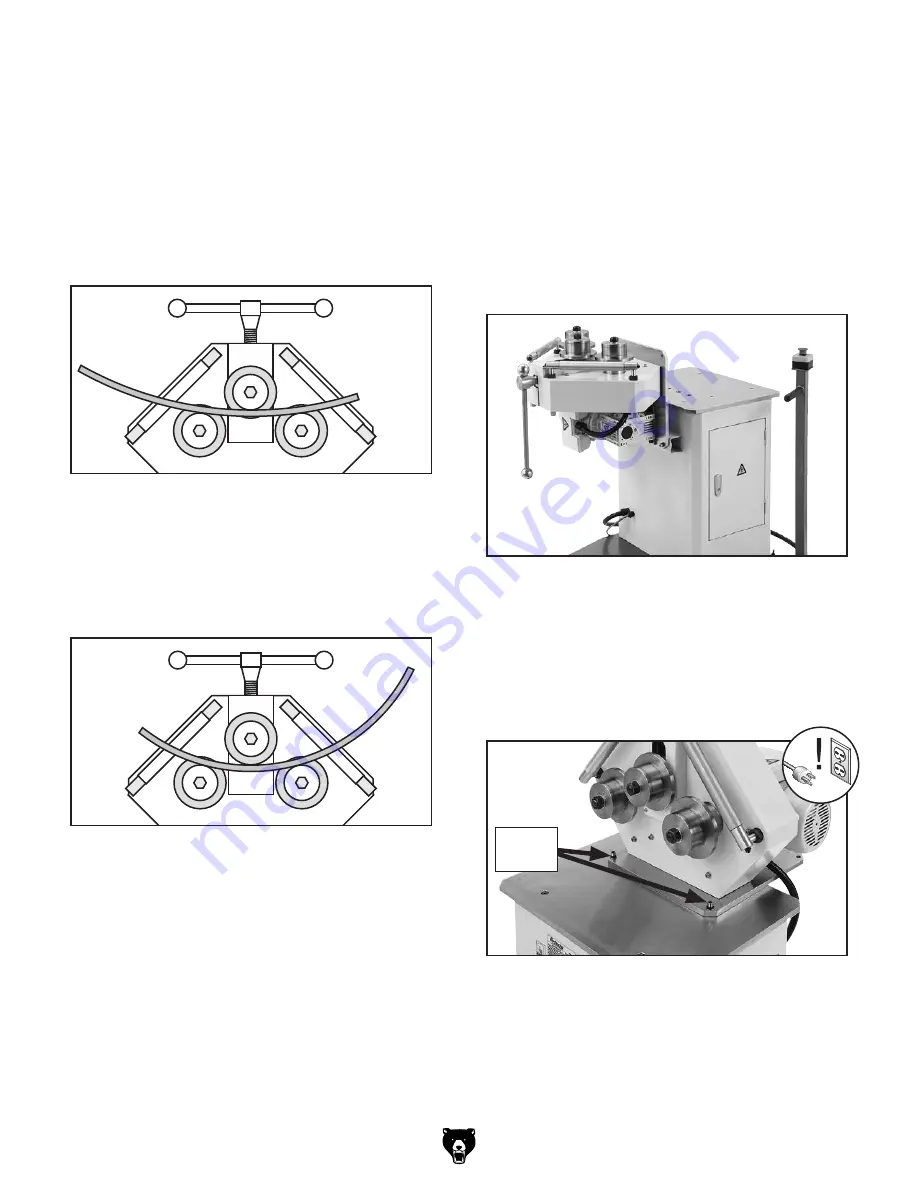

Positioning Headstock in Horizontal

Position

To roll a long arc, space constraints may make

it necessary to change the position of the head-

stock from the vertical to the horizontal position.

The back of the headstock is mounted to a hinge,

so it can be easily configured from one position to

the other (see

Figure 19).

Tool Needed

Qty

Hex Wrench 8mm .............................................. 1

Figure 19. Headstock tilted to horizontal position

for bending long arcs.

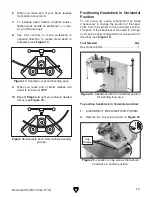

2. Remove two cap screws shown in Figure 20.

Figure 20. Location of cap screws that secure

headstock in vertical position.

Cap

Screws

To position headstock in horizontal position:

1. DISCONNECT MACHINE FROM POWER!

6. When you reach end of your bend, release

foot pedal to stop motor.

7. To increase bend (create a tighter radius),

tighten crank handle an additional

1

⁄

4

–

1

⁄

2

turn,

as you did previously.

8. Use foot controls to move workpiece in

opposite direction to create more bend in

workpiece (see

Figure 17).

Figure 17. Example of second bending pass.

Figure 18. Example bend after multiple bending

passes.

Содержание G0792

Страница 44: ......