Model G0764Z (Mfd. Since 10/15)

-25-

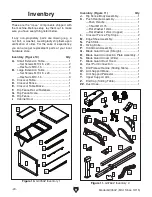

Assembly

The sliding table weighs nearly 200 pounds. It

must be lifted and carefully positioned onto saw

frame during assembly. If you are using a forklift

to lift and place it, you'll need to use lifting slings

around table to prevent scratching the aluminum

surface.

If you are not able to use the described forklift

method, the sliding table can be lifted into place

by four strong people—with one lifting from each

corner.

The only other part of the assembly that requires

additional help is installation of the extension

tables and blade guard arm. It takes approxi-

mately two hours to assemble the saw and make

the required adjustments to prepare the saw for

the test run.

To assemble sliding table saw:

1. Turn sliding table upside down, as shown in

Figure 16.

2. Insert (3) M12-1.75 x 50 T-bolts into T-slot

along bottom of sliding table (see

Figure 17),

and space them the same distance apart as

mounting holes in cabinet frame.

3. Lift sliding table over saw and lower T-bolts

into mounting holes on frame, as shown in

Figure 18.

Note: Make sure cap screw shown in Figure

18 is on outside of cabinet frame and against

mount edge.

Figure 17. T-slot along bottom of table.

T-Bolt

(1 of 3)

Figure 18. Inserting T-bolt into mounting hole on

saw frame.

T-Bolt

(1 of 3)

Cap Screw

Figure 16. Sliding table turned upside down.

Lifting heavy machinery

or parts without proper

assistance or equipment

may result in strains, back

injuries, crushing injuries,

or property damage.

Содержание G0764Z

Страница 21: ...Model G0764Z Mfd Since 10 15 19 5mm Hardware Recognition Chart ...

Страница 118: ......