-30-

G0516 Lathe/Mill

15.

Tighten the adjustable shafts and the gear

bracket cap screw. At this point, all gears

should not be able to move out of position.

16.

Turn the the chuck by hand to make sure that

all the gears turn smoothly.

17.

Replace the drive cover and secure it with

the knurled knobs.

18.

Test run the lathe to make sure it works prop-

erly before continuing with your specific

operation.

Reverse Threading

The Model G0516 can be setup to turn left-hand-

ed threads by adding another fixed-shaft gear

and moving the original fixed-shaft gear to anoth-

er mounting location.

Figure 44

shows the three

mounting locations for fixed-shaft gears (spindle

drive pulley is removed for clarity). For illustration

purposes, we label these mounting positions A, B

& C.

Figure 44.

Fixed-shaft gear mounting positions.

Figure 45.

Extra fixed-shaft gear.

To set up the gears for reverse threading:

1.

Disconnect the lathe/mill from the power

source!

2.

Locate the extra fixed-shaft gear (shown in

Figure 45

) in your inventory of loose parts.

A

B

C

Содержание G0516

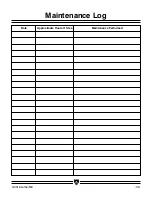

Страница 41: ...G0516 Lathe Mill 39 Maintenance Performed Approximate Hours Of Use Maintenance Log Date ...

Страница 46: ... 44 G0516 Lathe Mill Service Performed Approximate Hours Of Use Service Log Date ...

Страница 49: ...G0516 Lathe Mill 47 ...

Страница 71: ......