95

GB

• Take off the spark plug connector

(

12) and check the blade for wear

and damage.

• Always have a blunt blade resharpened

by a specialist company, as an imbal-

ance check can be carried out there.

• Always have a specialist workshop

change a damaged or imbalanced

blade.

Incorrect installation can result

in serious injury.

Adjusting the Carburettor

The carburettor has been preset in the

factory for optimum performance. If read-

justments are required, have the adjust-

ments made by a specialist workshop.

Maintenance Intervals

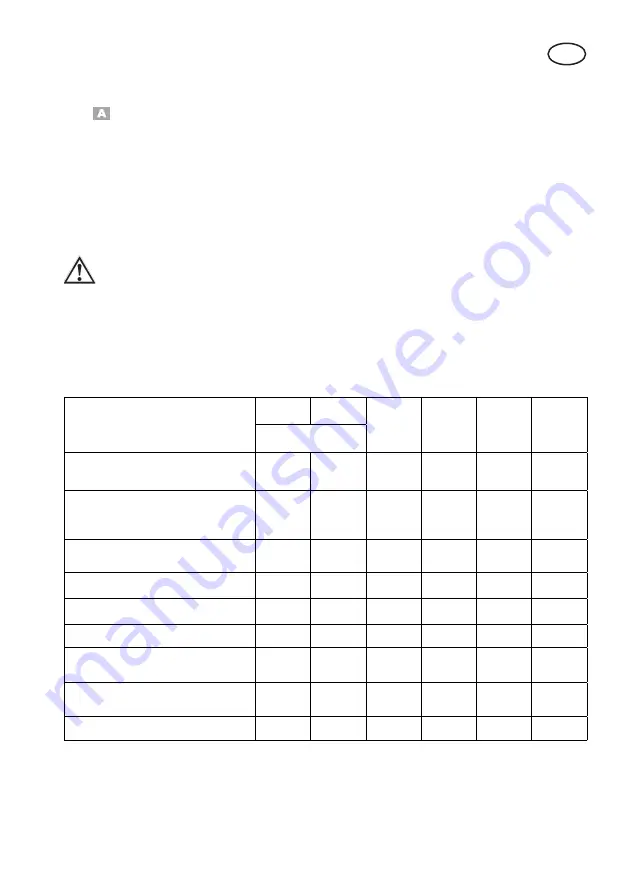

Regularly carry out the maintenance work listed in the “maintenance intervals” table.

Regular maintenance prolongs the life of the equipment. It also gives optimum cutting

performance and avoids accidents.

Maintenance Work

(See “cleaning and mainte

-

nance“)

Before

After After 1

st

5 Hrs.

After

8 Hrs.

After

50 Hrs. Annual

Work

Check and tighten screws, nuts

and bolts

Check the engine oil level/petrol

level and refill with engine oil/

petrol if required

Clean operating elements / the

area around the silencer

Clean the finger protection

b

Change the engine oil

Replace the air filter

a

Clean/adjust the spark plug

Replace the spark plug

Check the silencer and spark

catcher

b

Clean the air cooling system

a,b

a

Replace more often if there is a high level of dust or heavy dirt

b

See Briggs & Stratton instruction manual

Содержание BRM 46-125 BSA

Страница 3: ...3 29 30 24a 24 22a 36 37 5 6 4 31 25 23 22 27 27a 28 17 17a 21 ...

Страница 4: ...4 18 10 9 13 12 2a 1 0 5 0 6 mm 34 2b 2a 26 3 33 32 ...

Страница 204: ......