C R O S S C O U N T R Y F I V E - W A L L S E R I E S S T R A I G H T L E A N T O • G R E E N H O U S E I N S T R U C T I O N S

SEALING THE GREENHOUSE

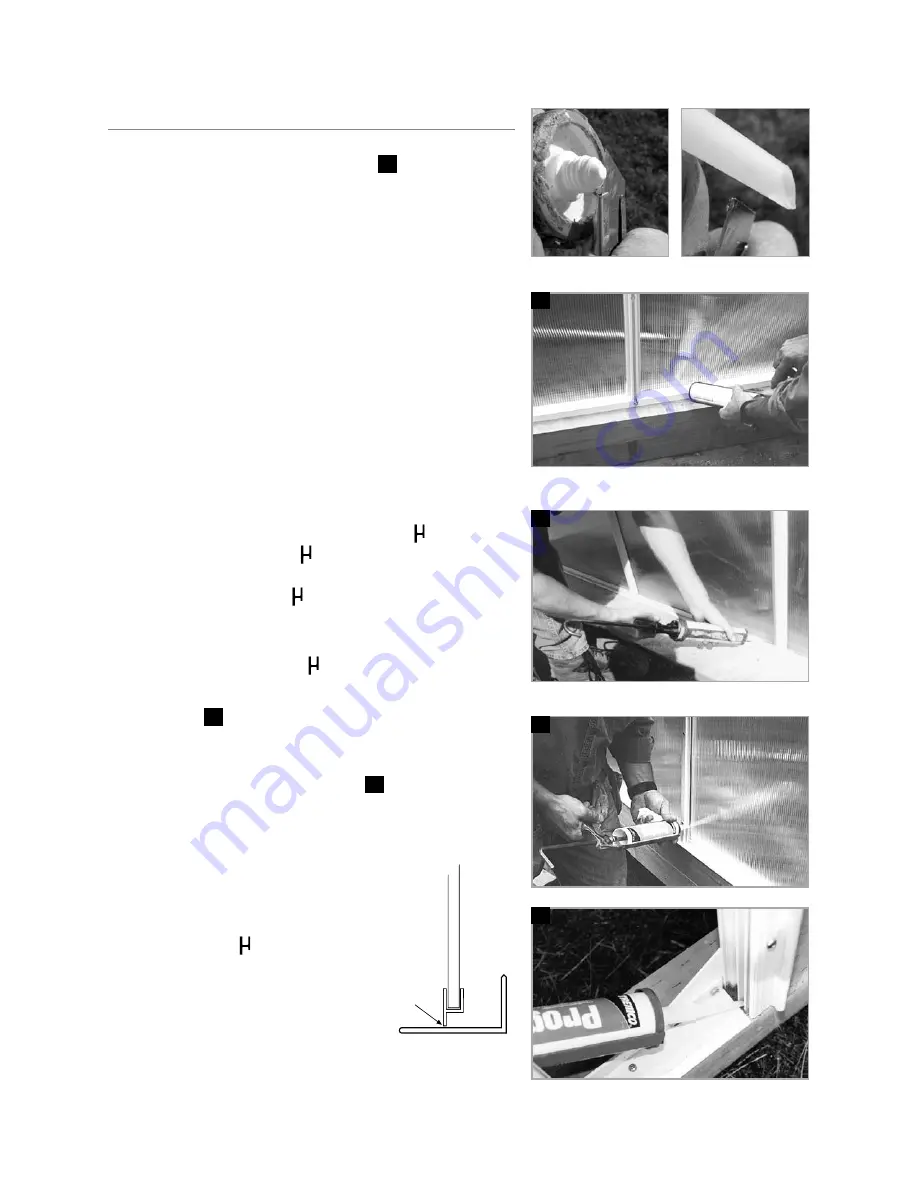

When all the polycarbonate sheets are installed, take a

tube of

CLEAR SILICONE SEALANT

(

A

) and seal all the

panels that fit into the aluminum

tracks on the

top, the bottom, the inside and the outside. In this way,

you can keep out most of the moisture from the end of the

panels. If this sealing process is not done, water may sit in

the bottom and fill the inside of the panels and grow

algae.

1. Unscrew the plastic nozzle on the tube of

silicone sealant.

2. Cut the top of the tube.

3. Screw on the plastic nozzle again.

4. Cut approximately 1/8” off the end of the plastic

nozzle at a 30-degree angle.

5. Put the tube into the caulking gun. When using

the gun, squeeze the handle slowly.

6. Wherever the polycarbonate sheets are sittng

in a side / base track or aluminm “ ”. Also seal

the inside of the “ ” on the ends and sidewalls

because greenhouse humidity runs down the

panels into the “ ” track.

7. Seal the vents before you slide them into place.

Seal the places where the panes fit into the door

frame bar and the “ ” under the above door

angle.

CAULKING

(

B

)

/ SEALING

(Do not get caulking on

polycarbonate, use only silicone)

• Sealthedoorframebarwherethebase/sill

meets the door frame.

(See

A

)

• Sealtheinsideofthebase/sillalongthe

perimeter of the foundation.

• Toporbehindtheridge

• Endbrsagainstthewall

Do Not seal the

“ ”

to the base! Any

condensation in the polycarbonate

needs to be allowed out.

(See additional pictures

on next page)

Inside view

Outside View

POL

YCARBONA

TE SHEET

Base

DO

NOT

SEAL

– 30 –

A

B

A

A