48

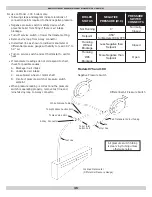

K.

Reinstall burner and mixer gasket and position

mixer assembly over studs. Install five (5) nuts but

do not tighten. Reinstall igniter and igniter gasket

and fasten with two (2) screws. Use care when

installing the igniter. Tighten five (5) nuts holding

mixer assembly.

L. Connect:

• Gas line to gas valve

• Condensate drain line to boiler

• Pressure switch hose to gas valve

• Air by-pass to mixer

•

1 ½” x 2” flexible coupling to air inlet and make

sure to put air baffle back to correct position

• Igniter wires

• Gas valve wires

3.

Visually inspect condensate lines leading from boiler

sections and vent pipe connector to condensate trap.

Refer to repair parts diagrams. Any foreign material or

debris visible in condensate lines needs to be cleaned

out as follows:

A. Disconnect condensate drain lines from condensate

trap.

B. Remove condensate trap and drain all water from

trap.

C.

Disconnect condensate lines from fitting on bottom

of boiler and vent pipe connector.

D. Run cold water through condensate lines and trap

to thoroughly flush out any sediment or debris.

E. Reinstall condensate trap and condensate lines.

F. Follow instructions under “Near Boiler Piping” for

filling condensate trap with water.

4.

Inspection of flue connector requires following steps. Refer

to repair parts diagram.

A. Loosen the clamp on the draft inducer end of the

2” vent pipe connector that connects the vent

to the draft inducer. Disconnect (unplug) wiring

harness from draft inducer motor and draft inducer

temperature safety switch. Remove four (4) bolts

that attach draft inducer to flue connector.

B.

Remove draft inducer and gasket from top of flue

connector.

C.

Inspect interior of flue connector. Any buildup of

sediment or aluminum oxide on inside surface must

be cleaned. Position draft inducer gasket and draft

inducer and fasten with four (4) screws. Be sure to

connect ground wire from draft inducer motor to

one of four mounting screws.

D. Connect wiring harness leads to draft inducer motor

and draft inducer temperature safety switch.

E. Connect vent pipe connector to draft inducer outlet.

MAINTENANCE AND CLEANING

Annual Examination And Cleaning Of Boiler

Components

DANGER

Before servicing, turn off electrical power to boiler

at service switch. Close manual gas valve to turn

gas supply OFF to boiler. Failure to comply will result

in death or serious injury.

!

NOTICE

Have qualified service agency perform the following

service procedures. Boiler owner should not attempt

these procedures.

1.

Before Servicing, turn off electrical power to boiler at

service switch. Close manual gas valve to turn off gas

supply to boiler.

2.

Cleaning Flue passages between boiler sections.

A. Any buildup of sediment or aluminum oxide (white

powdery or flaky substance) in flue passages must

be cleaned as follows.

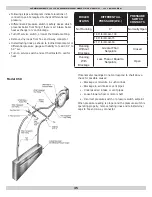

B.

Remove jacket front and top panels. Disconnect

condensate drain line from barbed fitting on bottom

of boiler. Keep open end of drain line above water

level in condensate trap to prevent trap from

draining. Disconnect pressure switch hose from

barbed fitting on gas valve. Disconnect 1½ x 2”

flexible coupling from air inlet. Disconnect air by-

pass (½” transparent vinyl tube) from bottom of

mixer.

C.

Remove air baffle from ½” x 2” flexible coupling

and clean air baffle if necessary. Refer to repair

parts diagram, mixer and pressure switch

assembly.

D.

Confirm manual gas valve is closed and disconnect

gas line to gas valve at union. Disconnect wires to

gas valve and igniter.

E.

Loosen but do not remove five (5) nuts attaching

mixer assembly to boiler. Remove two (2) igniter

screws and remove igniter.

F.

Remove five (5) nuts and remove mixer assembly.

Remove burner and mixer gasket.

G. Aluminum oxide deposits are water soluble and

may be rinsed away with spraying or running

water. Before rinsing, connect a ½” I.D. hose to

barbed fitting on bottom of boiler and run hose to

bucket or drain.

H. After rinsing, remove any remaining loosened

sediment using shop vacuum with snorkel

attachment.

I.

Inspect burner for any foreign matter in flame

ports or inside burner. Any foreign matter should

be removed by blowing with compressed air or

vacuuming.

J. Inspect interior of mixer for any signs of sediment

or aluminum oxide and clean if necessary.

NOTICE

Verify proper operation after servicing.

Содержание GM90-100

Страница 12: ...12 NEAR BOILER PIPING Figure 2 Single Zone Boiler Piping SAFETY RELIEF VALVE SEE PAGE 18 FOR REQUIREMENTS...

Страница 31: ...31 Figure 20 Field Wiring Connections ELECTRICAL WIRING SAFETY RELIEF VALVE SEE PAGE 18 FOR REQUIREMENTS...

Страница 33: ...33 Figure 22 Ladder Diagram for Figure 22 ELECTRICAL WIRING...

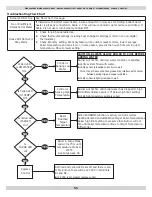

Страница 52: ...52 Troubleshooting Chart 1 TROUBLESHOOTING...

Страница 53: ...53 Troubleshooting Chart 2 TROUBLESHOOTING...

Страница 55: ...55 Troubleshooting Chart 4 TROUBLESHOOTING...

Страница 63: ...63 NOTES...