35

SETTING

OFF

Disables economy function. Will allow boiler to fire

until hi-limit temp is reached and re-fire with a 10°

subtractive differential.

LO

Provides lowest level of fuel savings. Use this set-

ting only if the house does not stay warm at higher

settings.

1

Recommended setting for single zone systems.

2

Recommended setting for Two zone systems.

3

Recommended setting for Three zone systems.

4

Recommended setting for Four zone systems.

5

Recommended setting for Five zone systems.

HI

Provides highest level of fuel savings.

C - Differentials

Differentials are automatic and will vary based on the

control settings and boiler temperature.

3 - Gas Control Valve

Electrically controlled Combination Gas Control Valve is

designed to meet requirements for use with hot surface

ignition found in this boiler. Valve is piped to gas/air mixer.

4 - Hot Surface Igniter

Igniter is mounted next to burner through gas/air mixer.

The igniter also serves as means for proving main burner

flame by flame rectification. In the event of a lack of flame

signal on three (3) consecutive trials for ignition, IBC will

flash the VALVE light when locked out due to failed ignition.

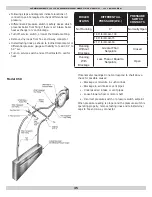

5 - Draft Inducer Temperature Safety Switch

Draft Inducer Temperature Safety Switch is a disc

thermostat (180°F setpoint) located on induced draft fan

outlet port. Switch protects inducer and vent pipe from

potential high temperature condition for discharging flue

gases. Condition would typically be result of higher high

limit control setting or over firing. Temperature safety

switch automatically resets when the vent temperature

decreases. (15°F switch differential).

6 - Casting Temperature Safety Switch

In event of lack of or loss of water in boiler, Casting

Temperature Safety Switch (300 °F setpoint) installed

on top of the aluminum boiler section shuts off boiler by

shutting off power to Integrated Boiler Control (IBC). This

fault requires manual reset of casting temperature safety

switch to restart the boiler. Verify that boiler is properly

filled with water before resetting this switch.

Never run cold water into a hot empty boiler.

CONTROLS AND ACCESSORIES

7 - Differential Pressure Air Proving Switch/

Blocked Vent Safety Shutoff

Differential pressure switch monitors air flow by sensing

differential pressure measured in inches of water (” w.c.).

Pressure switch contacts close when draft inducer is

running. Closed switch indicates there is adequate air flow

for combustion. Pressure switch shuts off main burner if

differential pressure is inadequate due to blocked vent pipe,

blocked air intake, blocked boiler sections, or blocked draft

inducer. If pressure switch does not close within 5 minutes

of blower being turned on, control locks out with PURGE

light flashing to indicate pressure switch fault.

8 - Draft Inducer

Draft inducer (blower) provides means for pulling

combustion air into and through the mixer, burner, flue

ways of cast aluminum boiler sections and flue adapter

before being discharged through vent piping to outdoors.

See applicable sections for proper sizing and installation of

combustion air and vent piping in this manual.

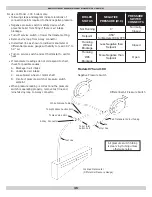

9 - Circulator Pump (Optional)

Every forced hot water system requires at least one

circulating pump.

Circulating pump imparts the necessary energy to move

water through closed loop supply and return piping

systems, terminal heating equipment (i.e. finned tube

radiators, etc.) and back through boiler for reheating.

To provide required hot water flow rates, circulator pump

must be properly sized to overcome frictional losses

(usually measured in feet of water, also referred to as

“pump head loss”) of supply and return piping systems and

boiler.

The circulator pump is furnished for single zone or zone

valve controlled heating system and should be located on

downstream (i.e., pumping away) side of expansion tank.

For pump controlled system (where there is a circulator for

each zone) circulator provided with boiler can work for one

zone. For more details on piping and circulators, see “Near

Boiler Piping” on page 11.

10 - Drain Valve

Manual drain valve provides means of draining water in

heating system, including boiler and hot water supply and

return piping systems installed above drain valve. This

drain valve is installed in ¾” tapping at bottom of front

boiler section. Any piping installed below elevation of

this drain valve will require additional drain valves to be

installed at low points in piping systems in order to drain

entire system.

Содержание GM90-100

Страница 12: ...12 NEAR BOILER PIPING Figure 2 Single Zone Boiler Piping SAFETY RELIEF VALVE SEE PAGE 18 FOR REQUIREMENTS...

Страница 31: ...31 Figure 20 Field Wiring Connections ELECTRICAL WIRING SAFETY RELIEF VALVE SEE PAGE 18 FOR REQUIREMENTS...

Страница 33: ...33 Figure 22 Ladder Diagram for Figure 22 ELECTRICAL WIRING...

Страница 52: ...52 Troubleshooting Chart 1 TROUBLESHOOTING...

Страница 53: ...53 Troubleshooting Chart 2 TROUBLESHOOTING...

Страница 55: ...55 Troubleshooting Chart 4 TROUBLESHOOTING...

Страница 63: ...63 NOTES...