❏

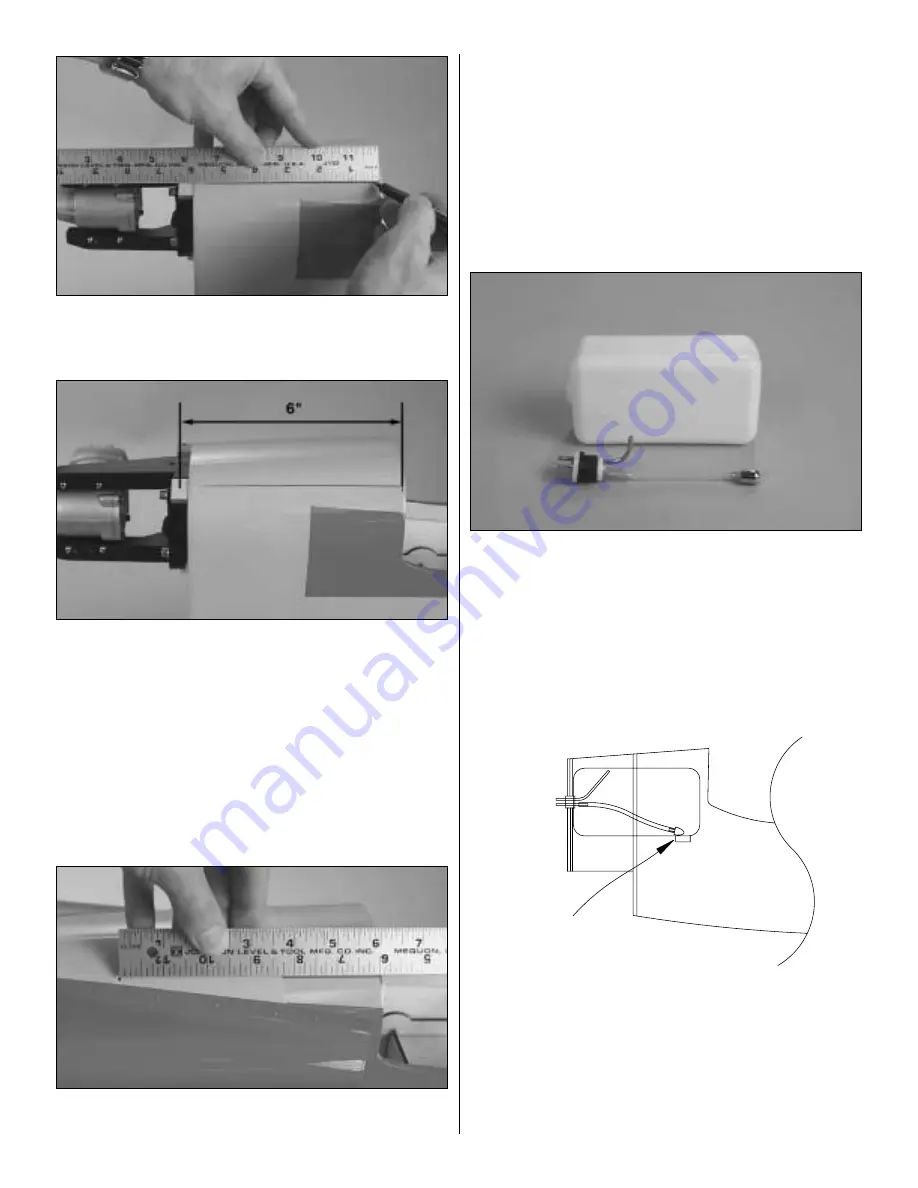

2. Hold a ruler to the fuse centered on one of the cowl

mounting blocks. Use a felt-tip pen to draw a line directly

onto the fuse along the straightedge.

❏

3. Mark a reference point on the end of the line exactly

6" from the center of the cowl mounting block.

❏

4. Mark the location of the remaining three cowl mounting

blocks the same way.

❏

5. Place the cowl on the fuse. Mount the spinner and prop

to the engine. Position the cowl on the fuse so it is in

alignment with the spinner. Be certain there is at least a

3/32" gap between the front of the cowl and the back plate

of the spinner. It may be helpful to have an assistant hold the

cowl for you.

❏

6. Align the ruler with the line on the fuselage. Mark the

center of the cowl mounting block on the cowl 6" from the

reference point. Drill a 3/32" hole through cowl and the

mounting block at the mark. Enlarge the hole in the cowl only

with a 1/8" drill. Mount the cowl to the block with a #4 x 3/8"

screw and #4 washer.

❏

7. With your assistant holding the cowl in position, mark,

drill and mount the cowl to the remaining three cowl

mounting blocks the same way.

Before finishing the cowl, now is a good time to install the

fuel tank...

❏

8. Arrange the stopper and tubes as shown in the photo,

then insert them into in the tank. Tighten the screw to

expand the stopper, thus sealing the tank. Be certain the fuel

line weight (clunk) at the end of the fuel line inside the tank

does not contact the rear of the tank. Otherwise, the line

may become stuck above the fuel level and discontinue fuel

flow. Remember (or use a felt-tip pen to mark) which tube is

the fuel pick-up tube and which tube is the vent (that will be

connected to the pressure fitting on the engine muffler).

❏

9. Install the tank in the fuse. Fit the neck through the

hole in the firewall. Be certain the vent tube inside the tank

is pointing upward. Cut the 1/4" x 3/4" x 5" balsa stick to the

correct length to fit between the fuselage sides under the aft

end of the tank (the approximate length will be 4-11/16").

Position the “fuel tank support” in the fuse, then glue it into

position. If necessary, the support may be broken free to

remove the tank when maintenance is required.

BALSA FUEL

TANK SUPPORT

16