❏

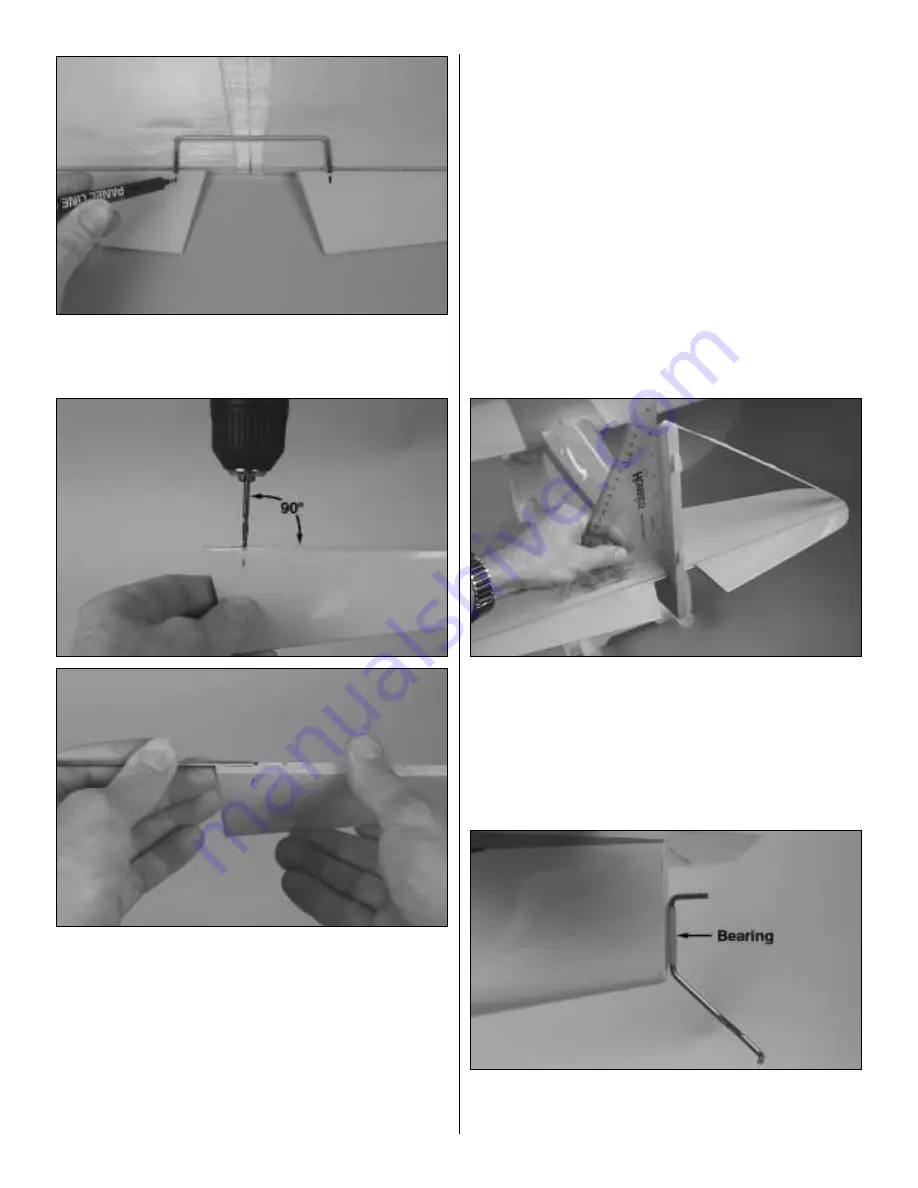

11. Position the elevator joiner wire, evenly spaced,

over both elevators as shown in the photo. Mark the ends of

the joiner wire onto the elevators.

❏

12. Drill a 1/8" hole through the LE of both elevators at

the marks you made. Use a Great Planes Groove Tube

(GPMR8140) or a 1/8" brass tube sharpened on the end to

cut a groove in the LE of the elevators to accommodate the

joiner wire. Test fit elevators to stab with joiner wire. “Tweak”

the joiner wire if necessary to get both elevators even.

❏

13. Use 30-minute epoxy to glue the stab into the fuse.

For the most strength, apply epoxy to both sides of the stab

and inside the fuse where the stab fits. Slide the stab and

the elevator joiner wire into position. Wipe away residual

epoxy with a tissue dampened with alcohol. If the stab

required a weight on one side or the other to align it with the

fuse, position the weight. Use the pin and string to confirm

stab alignment. If you've cut the covering as suggested over

the slots in the fuse for the stab (leaving a 3/32"

flap that can

be ironed to the stab), use a trim iron to iron the covering to

the stab before the epoxy hardens. Do not disturb the model

until the epoxy has fully hardened.

❏

14. Thoroughly coat the insides of the holes in the

elevators for the joiner wire with 30-minute epoxy. Also coat

the ends of the joiner wire that go into the elevators. Join the

elevators to the stab and the joiner wire with the hinges.

Wipe away excess epoxy before it hardens. The same as

you did the ailerons, permanently join the elevators to the

stab by gluing in the hinges with thin CA.

❏

15. Fit the fin into the fuse. Just the same as you did the

stab, mark the outline of the fuse onto the fin, then use the

soldering iron technique to remove the covering. Glue the fin

into position with 30-minute epoxy using a builder's square

to make certain the fin is vertical. If necessary, pull the fin to

one side or the other with masking tape until the fin is

perpendicular to the stab.

❏

16. Use a #11 blade or a small razor saw to cut a slot in

the aft end of the fuse for the nylon bearing on the tail gear

wire. Test fit the tail gear wire into the fuse as shown.

11