Refer to this photo for the following two steps.

❏

2. Cut the covering from the pre-drilled holes in both wing

halves for the servo wires, the wing dowels and the wing

bolts. Guide the end of the servo wires through the holes in

the top of both wing halves.

❏

3. Test fit the forward wing joiner and the plywood aft

wing joiner in both wing halves. Make adjustments where

necessary for a good fit.

❏

4. Test fit the wing halves together. There should be no

gap. When one wing is lying flat on the workbench, the tip of

the other wing should be approximately 6-5/8" [168mm] from

the workbench. Make adjustments where necessary.

❏

5. Separate the wings and remove the joiners. Thoroughly

coat all mating surfaces, including the inside of the wings

where the joiners fit, with 30-minute epoxy, then glue the wings

together. Use masking tape to tightly hold the wings together

until the epoxy has hardened. Excess epoxy that gets on the

covering can be easily removed before it hardens with a tissue

dampened with denatured alcohol or other suitable solvent.

❏

6. Round one end of both hardwood wing dowels. Use

epoxy to glue the dowels in the wing with the rounded ends

forward. Be certain approximately 1/2" [13mm] of the dowels

protrudes from the wing. While you've got some epoxy

mixed up, lightly coat the dowels to fuelproof them.

❏

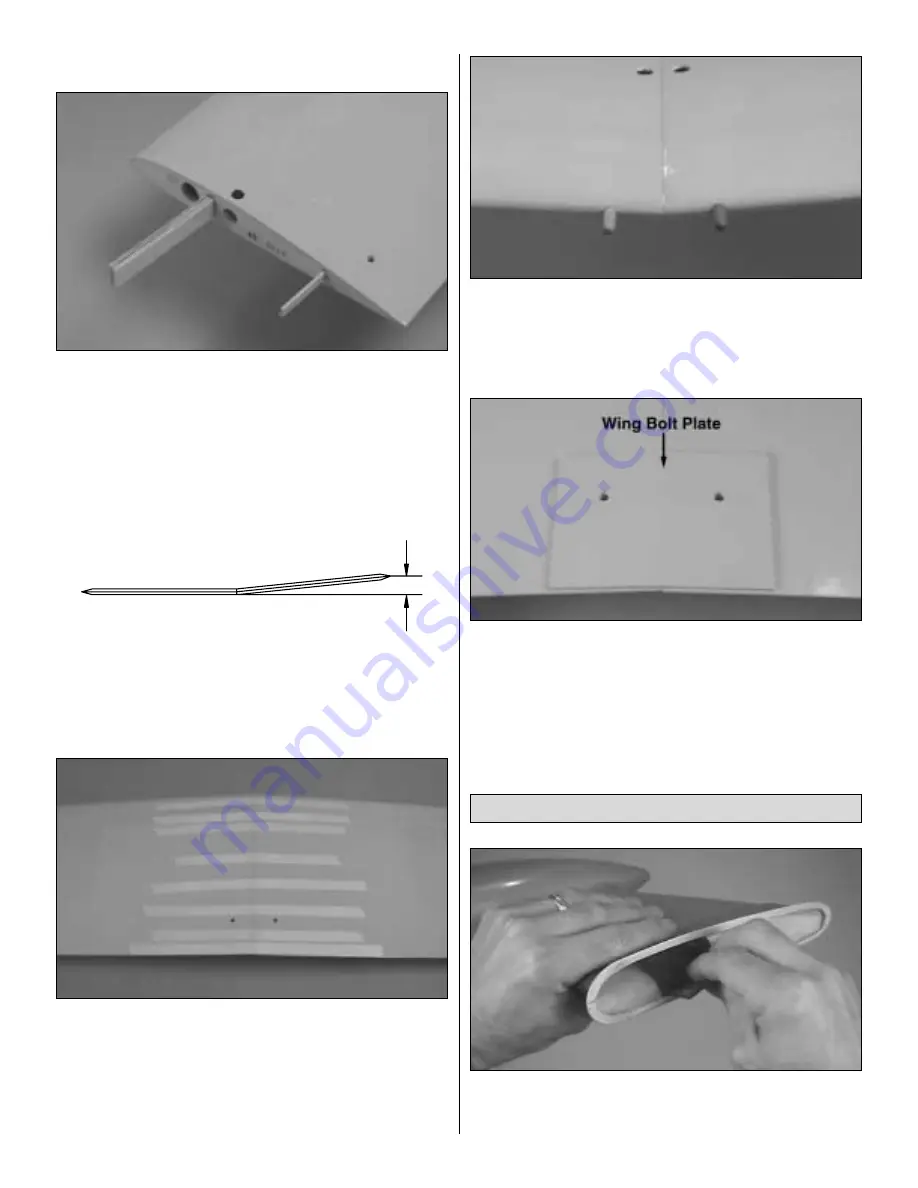

7. Use a sharp, new #11 blade to trim the covering from

the bottom of the wing for the 1/8" [3mm] plywood wing bolt

plate. Use care to cut just through the covering, while not

cutting into the wood. Glue the wing bolt plate into position.

After the glue hardens, use the holes in the top of the wing

as a guide to drill 17/64" [6.7mm] (or 1/4" [6.4mm]) holes

through the wing bolt plate.

❏

1. Use coarse sandpaper to roughen the inside of the

rim

near the front and back of both wheel pants. The areas

specified are indicated by the brackets in the following photo.

Mount the Landing Gear

6-5/8"

10