Section 1: Assembly & Set-up

NTS2507, NTS2509, & NTS2511 s/n+ 2019+ NTS Seeder 313-900M

7/1/19

11

Section 1: Assembly & Set-up

Tractor Requirements

WARNING

!

To avoid serious injury or death:

•

•

Make certain tractor’s 3-point lifting capacity and weight

is capable of lifting and controlling the seeder under all

operating conditions. Refer to “

Specifications &

Capacities”

on page 66 for seeder weight.

Tractor horsepower and hitch category should be within

the range noted below. Tractors outside the horsepower

range must not be used.

Pull-Type Hitch Minimum Horse Power

NTS2507 . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 hp

NTS2509 . . . . . . . . . . . . . . . . . . . . . . . . . . . .80 hp

NTS25011 . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 hp

3-Point Hitch Minimum Horse Power

NTS2507 . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 hp

NTS2509 . . . . . . . . . . . . . . . . . . . . . . . . . . . .90 hp

NTS25011 . . . . . . . . . . . . . . . . . . . . . . . . . . . 110 hp

3-Point Hitch Category

NTS2507 without Native Seedbox . . . . . . . . . Cat. I

NTS2507, NTS2509, & NTS2511 . . . . . . . . . Cat. II

Hydraulic Hook-up

Pull-Type Hitch . . . . Duplex outlet with factory float

3-Point Hitch . . . . . . . . . . . . . . . . . . . . . . . . . None

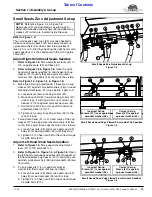

Electrical Hook-up (See Figure 1-1) . . . . . 7-Pin Outlet

Tractor 7-Pin Electrical Outlet

Figure 1-1

IMPORTANT:

The lower 3-point arms must be

stabilized to prevent side-to-side movement. Most

tractors have sway blocks or adjustable chains for

this purpose.

11640

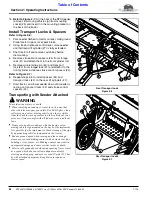

Quick Hitch Compatibility

The NTS Seeders are quick hitch compatible. Make sure

your quick hitch lift capacity is rated for picking up and

transporting a fully loaded seeder. Use Land Pride’s

QH20 Quick Hitch or one that is compatible.

Torque Requirements

Refer to

“Torque Values Chart for Common Bolt Sizes”

on page 70 to determine correct torque values when

tightening hardware. See

bottom of chart for exceptions to common torque values.

Dealer Preparations

This NTS Seeder has been mostly assembled at the

factory. Some preparation will be necessary to attach the

seeder to the customer’s tractor. Make sure the intended

tractor conforms to

listed on

this page.

Go through the

below before

assembling the NTS Seeder. Speed up the assembly

task and make the job safer by having all needed parts

and equipment readily at hand.

Assembly Checklist

Check

Reference

All major frame components

Operator’s

Manual

Location of fasteners and pins.

NOTE:

All hardware from the factory has

been installed in the location where it

will be used. If a part is temporarily

removed for assembly reasons,

remember where it goes. Keep parts

separated.

Operator’s

Manual

313-629M

Be sure the part gets used in the correct

location. Use parts manual to identify

location of parts that have been

removed. By double checking while you

assemble, you will lessen the chance of

using a part incorrectly that may be

needed later.

Parts

Manual

313-629P

All working parts are moving freely, bolts

are tight and cotter pins are spread.

Operator’s

Manual

All grease fittings are in place and

lubricated.

Proper take-up and alignment of all drive

chains.

Safety decals are correctly located and

legible. Replace if damaged.

Pages

IMPORTANT:

Use a quick hitch designed to lift and

transport the seeder fully loaded. Using a quick hitch

not designed to handle the seeder weight can

damage your quick hitch, seeder, and tractor.