3.2.2 TWO PIPE CONNECTION

For either a two pipe (sub gravity) or a single pipe (suction)

system with a deaerator, the following additional items will be

required:

•

Flexible fuel hose ⅜ʺ male x ¼ʺ female (product code:

RBS36 - 900 mm / product code: RBS36XS - 600mm)

•

⅜ʺ x ¼ʺ BSP adaptor (product code: Z3003602)

•

¼ʺ isolating valve (product code: ISOLATION1/4)

These are available to purchase from Grant UK.

Connect the oil supply to the burner oil pump as follows:

1.

Fit the flexible fuel hose (supplied with the boiler) to the

suction port of the burner oil pump, as detailed in Section

3.2.1.

With either a two pipe (sub gravity) system or a single pipe

(suction) system with a deaerator, the by-pass screw (supplied

with the boiler) must be fitted to the burner oil pump as follows:

1. Unscrew and remove the blanking plug from the return port

on the burner oil pump and discard it.

2. Fit the by-pass screw into the threaded hole (inside the return

port) and fully screw it in using an Allen key.

3.

Fit the nut of the elbow connection on the flexible fuel hose

into the return port and tighten.

4.

Fit the ¼ʺ isolating valve (not supplied) to the end of the rigid

oil return pipe (to the deaerator or oil tank) using a fitting to

suit the pipe size and type (not supplied).

5.

Connect the other end of the flexible fuel hose (not supplied)

to the isolating valve using a ⅜ʺ x ¼ʺ BSP adaptor (not

supplied).

6.

Re-fit the burner to the boiler.

Section 3: Oil Storage and Supply System

Page 13

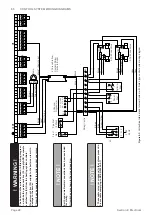

3.2.1 SINGLE PIPE (GRAVITY) CONNECTION -

REFER TO FIGURE 3-5

Connect the oil supply to the burner oil pump as follows:

1. Unscrew and remove the plastic blanking plug from the

suction port of the burner oil pump and discard it.

2.

Fit the nut of the elbow connection on the flexible fuel hose

(supplied with the boiler) into the suction port and tighten.

3.

Fit the ¼ʺ isolating valve (supplied with the boiler) to the end

of the rigid oil supply pipe using a fitting to suit the pipe size

and type (not supplied).

4.

Connect the other end of the flexible fuel hose to the isolating

valve using the ⅜ʺ x ¼ʺ BSP adaptor (supplied with the

boiler).

5.

Re-fit the burner to the boiler.

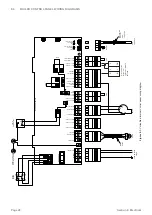

2

3

5

6

7

1

8

4

Figure 3-5:

Riello oil pump

Item

Description

1

Inlet (suction) port

2

Return port

3

By-pass screw

4

Pressure gauge port

5

Pressure adjustment

6

Vacuum gauge port

7

Solenoid

8

Auxiliary pressure test point