6-5

Chapter 6: Maintenance and Service

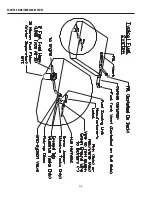

Scuppers

Grady-White boats have self-bailing cockpits meaning water on the cockpit floor drains by

gravity through large aft scuppers and

not

into the bilge. The aft drains (scuppers) have an external

scupper flap assembly that restricts the flow of water back into the boat. Inspect the flaps

periodically to make sure they are free of debris. The scupper flaps may need periodic replacement

if the rubber becomes damaged or no longer seals properly in the thru-hull.

In addition to inspecting the scuppers, annually inspect the hoses and replace if necessary. To

inspect hose, observe water flow between the cockpit and the thru-hull. If water flow seems

restricted, a high pressure water hose can be used to flush debris from the scupper hose. If water

leaks into the hull interior from the hose or fittings, replace these components immediately before

using the boat.

Caulking/Gasket

Deck fittings, bow rails, windows, hatches, etc. have been caulked or gasketed with the highest

quality material to ensure a waterproof joint with the boat. However, the working action of normal

use will tend to flex the joint and eventually break down the seal between them. Periodically inspect

the caulking or gaskets for leaks. Recaulk or replace the gaskets as necessary, or have your dealer

do the repair.

Hardware/Stainless Steel Rails

The hardware on your Grady-White is made of laboratory grade 316 stainless steel and needs

regular cleaning to maintain its “less staining” properties. The key to maintaining your stainless

steel is to keep it clean with a mild solution of soap and

fresh

water. Remove salt or dirt from your

stainless steel on a regular basis.

Hardware Mounting

When fastening new hardware to the boat, be sure to seal the opening properly with silicone or

5200 to prevent leakage into the laminate or into the boat.

Aluminum Components

(Lean Bars, Rod Holders, T-top and Hardtop Frames, Outriggers, Etc.)

Due to the nature of aluminum and the harsh exposure conditions of the marine environment, it

is important to follow a

required maintenance procedure

. Failure to follow a preventative

maintenance procedure will most likely result in aluminum pitting.

Both painted and anodized aluminum parts must be washed periodically with a very mild soap

and water solution. Grady- White recommends washing with a mild soap (such as Ivory

®

Liquid)

after each use and every two to three weeks if stored in an outside marine environment. Strong

cleaners and soaps must not be used. Never use abrasive cleaners or products that contain chlorine

bleach. These products can remove paint and anodized coating.

Содержание Canyon 306

Страница 2: ......

Страница 10: ...1 4 Chapter 1 Consumer Information ...

Страница 26: ...3 8 Chapter 3 General Information ...

Страница 32: ...4 6 Chapter 4 Performance ...

Страница 43: ...6 7 Chapter 6 Maintenance and Service ...

Страница 44: ...6 8 Chapter 6 Maintenance and Service ...

Страница 72: ...9 4 Chapter 9 Warranty ...