Electro-pneumatic Control Panel Display Screens

Setting

Setting

Setting K

K

K---Factor

Factor

Factor

In order for a batching cycle to accurately measure

product, the K-Factor must be appropriately set and

the system outlet fluid lines fully loaded.

A calibration routine can be run to validate/adjust the

K-Factor setting.

1.

Complete the current Job to reset the batch

amount.

2.

Dispense desired test amount of material.

3.

Validate the actual amount of material dispensed

(volume or mass).

4.

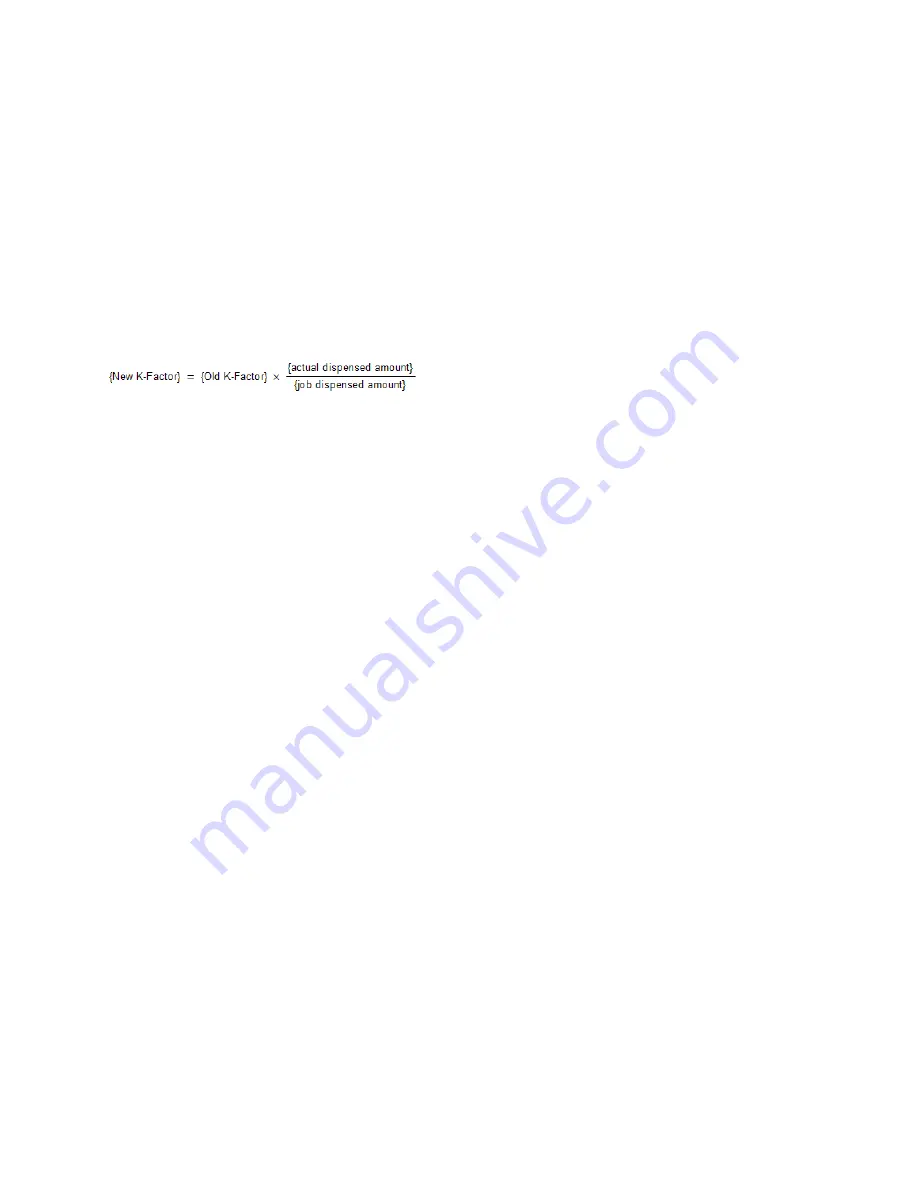

Calculate and enter the new K-Factor:

NOTE:

NOTE:

NOTE: If using “Pulse Meter (Mass)” and the

product density changes, the K-Factor value must

be re-calibrated. Otherwise, the batch may not be

accurate.

Setting

Setting

Setting Scale

Scale

Scale Feedback

Feedback

Feedback

In order for a batching cycle to accurately measure

product, the 4 mA Mass and 20 mA Mass settings for

the Scale (Positive) or Scale (Negative) must be set

appropriately.

• 4 mA Mass: Set this value to the actual weight

of the product setting on the scale (including the

container) when the output of the scale is 4 mA.

• 20 mA Mass: Set this value to the actual weight

of the product setting on the scale (including the

container) when the output of the scale is 20 mA.

Although the unloader system only uses differences

in weights during batching, it is important to use the

same container when setting 4 mA Mass and 20 mA

Mass values. After the values are set, the actual

weight of the container is not important.

NOTE:

NOTE:

NOTE: If product density changes, the 4 mA Mass

and 20 mA Mass values must be re-set. Otherwise

the batch may not be accurate.

3A5416E

55