14

308357

Service

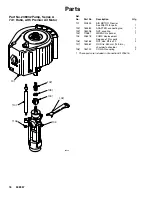

DISPLACEMENT PUMP SERVICE

Disassembly

When disassembling the pump, lay out all the removed

parts in sequence, to ease reassembly.

NOTE:

Repair Kit 237166 is available. For the best

results, use all the new parts in the kit. Kit parts are

marked with an asterisk, for example (3*). Kits to

convert the pump to different packing materials are

also available. Refer to page 20.

1.

Place the pump lengthwise in a large vise, with the

jaws on the outlet housing (9) as shown in Fig. 5.

Using the supplied wrench (104), loosen, but do

not remove, the packing nut (2).

2.

Using a pipe wrench, unscrew the intake valve

(17) from the intake housing (16). Be careful to

catch the intake ball (15) as you remove the intake

valve, so that it doesn’t fall and suffer damage.

Remove the o-ring (28) from the intake valve.

Inspect the ball and the seat (D) of the intake valve

for wear or damage. See Fig. 5.

3.

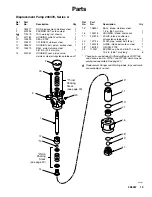

Stand the pump upright in the vise. Remove the

six long cap screws (29), using a 15/16 in. (or 23

mm) socket wrench. See Fig. 8.

4.

Lift the outlet housing (9) straight up off the pump.

Be careful not to scratch the displacement rod (1)

while removing the housing. See Fig. 6.

5.

Lift the cylinder (11), displacement rod (1), and

piston assembly off the intake housing (16). Re-

move the ball guide (27) from the intake housing,

and inspect the guide surfaces. See Fig. 6.

6.

Using a rubber mallet, drive the displacement rod

(1) and piston assembly out the bottom of the

cylinder (11) until the piston comes free. Pull the

rod and piston from the cylinder, being careful not

to scratch the parts.

CAUTION

To reduce the possibility of costly damage to the rod

(1) and cylinder (11), always use a rubber mallet to

drive the rod out of the cylinder. Never use a ham-

mer to drive the rod.

7.

Shine a light into the cylinder (11) to inspect the

inner surface for scoring or wear. Remove the

o-rings (10) from the cylinder.

8.

Place the flats of the piston seat housing (14) in a

vise, as shown in Fig. 7. Using an adjustable

wrench, unscrew the piston ball housing (12) from

the piston seat housing. Be careful to catch the

piston ball (13) as you separate the piston seat

housing and ball housing, so that it doesn’t fall and

suffer damage.

03986

Fig. 5

1

9

11

16

17

1

Torque to 522–542 N.m (385–400 ft–lb).

1

28*

15*

D

2

2

Lubricate.

2

2

Содержание Dura-Flo 1100

Страница 10: ...10 308357 Notes ...