INSPECTION AND MAINTENANCE SCHEDULE

*Federal, state and local codes may require inspection and maintenance checks more often. Please check

the federal, state and local code manuals in your area. Gorbel recommends a certification inspection

interval of no more than one year by a qualified person.

26

10/12 Rev. E

WARNING

Any changes in rolling effort or unusual noises must be immediately identified and corrected. It is not necessary to

lubricate the track or bearings. Lubricating may attract airborne particles and may increase the rolling resistance.

Do not use such substances as WD40®, silicone sprays, oil or grease.

600 Fishers Run, P.O. Box 593

Fishers, NY 14453-0593

© 2012 Gorbel Inc.

All Rights Reserved

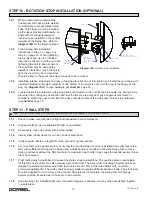

GORBEL® TETHER TRACK® SWING ARM INSPECTION AND MAINTENANCE SCHEDULE

ITEM COMPONENT

MAINTENANCE

FREQUENCY*

1

Mounting Bolts

Check that lockwashers are compressed and nuts tightened to

manufacturers specifications.

Every 500 hours

or 3 months

2

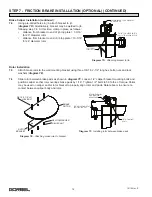

Pivot Assemblies Check that lockwashers are compressed. Check for wear on thrust

washers. Grease fittings (use Lubriplate #630-AA or equivalent).

Every 1000 hours

or 6 months

3

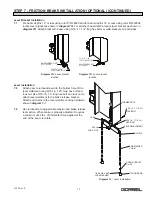

End Stops

Check for full compression of lockwasher. If thru-bolt is exposed,

replace endstops.

Every 2000 hours

or yearly

4

Tether Trolley™

Connector

Check eyenut for wear. Check that clamp plate lockwashers are

compressed. Check that black spring washer is not deformed and is in

place. Confirm spring pin is in place. Check for smooth rolling action.

Recover Trolley only:

Check that guide bushing bolts are tightened to

10 ft-lbs and bushings spin freely.

Every 2000 hours

or yearly

5

Wheels

Check for cracks, pits and/or grooves: all of these increase pull

forces. If any of these conditions exist, wheels should be replaced.

Every 2000 hours

or yearly

6

Accessory Items

Conduct a general inspection of all accessory items.

Every 1000 hours

or 6 months

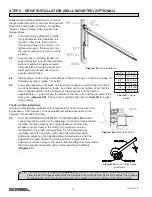

7

Tether Track®

Swing Arm

Conduct a visual inspection of wall cantilever Swing Arm weldment,

Tether Track® and mast weldment.

Every 1000 hours

or 6 months

8

Capacity and

Warning Labels

Check that all labels are in place and legible. Replace labels if

damaged or illegible.

Every 2000 hours

or yearly

9

Connecting

Equipment

Inspect all protective equipment connected to the Tether Track®

Anchorage System following the operation and maintenance manuals

provided for each piece of equipment.

As required by

manufacturer

1

2

3

4

5

Free Standing

Swing Arm

Wall Mounted

Swing Arm

WARNING

This product can expose you to chemicals, including acrylonitrile,

which are known to the State of California to cause cancer. For

more information go to:

www.P65Warnings.ca.gov

Distributed by Engineered Fall Protection

Sales@EngineeredFallProtection.com

www.EngineeredFallProtection.com

Tel: (314) 492-4422