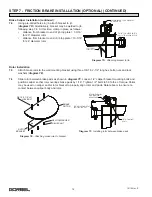

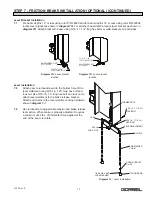

STEP 3 - FREE STANDING MAST INSTALLATION (CONTINUED)

3.1 INSTALLING ANCHOR BOLTS (CONTINUED)

3.1.3 Post-Installed Anchor Bolts with Shallow Foundations (6 bolt pattern):

In addition to the requirements identified in

Step 1.4

, a minimum 6” thick reinforced concrete floor that is

free of cracks, seams, expansion joints, and walls is required. Foundation requirements are based on a

concrete compressive strength of 3000# per square inch, a soil bearing pressure of 2500# per square foot,

and a modulus of subgrade reaction of 150# per square inch per inch.

A) Anchor bolts (by others) must:

• have an ICC-ES listing demonstrating suitability for the application.

• be installed in accordance with the manufacturer’s instructions and requirements.

B) Base plate may be used as a template to drill holes in concrete floor. Follow anchor bolt manufacturer’s

recommendations for drill bit size, depth, and special inspection requirements.

Note:

Base plates are designed for poured foundations. Hole size may exceed anchor bolt manufacturer’s

recommendations. Contact Gorbel® Customer Service if a custom base plate is required. Drill

bushings or equivalent may also be used to reduce hole clearance. Bushings must not protrude above

base plate. If base plate hole diameter is greater than

bolt diameter plus 1/4”, refer to AISC Design Guide 1 for

minimum washer size and thickness recommendations.

C) Install anchor bolts and hardware according to

manufacturer’s installation instructions.

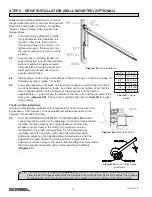

Diagram 3D

shows

a typical installation.

Note:

Before tightening hardware, follow instructions in

Step

3.2

for applying and curing grout.

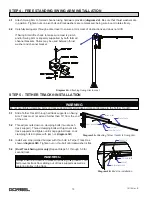

3.2 Installing and Plumbing Mast

A) Cover entire base plate area with one inch of non-shrink precision grout.

B) Set mast into place and make sure that the base plate is completely

seated in the grout.

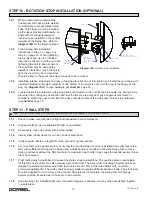

C) Thread a plumb line through Swing Arm mounting bracket holes and

hole in tapered plug (by others) as shown in

diagram 3E

.

D) Adjust mast as required until plumb line is centered in all the mounting

hole brackets.

E) Once mast is plumb

and grout has cured

, fully

tighten anchor bolt hardware.

F) Verify mast is still plumb.

DO NOT USE A LEVEL

TO PLUMB MAST.

WARNING

Shallow foundations are only appropriate for 8 foot span, one worker Swing Arms.

A A

6"

4"

1"

GROUT

EFFECTIVE

EMBEDMENT

QUALIFIED ADHESIVE

BASE PLATE W/

STIFFENER

1-1/2" OD X 1-1/8" ID

X 1" BUSHING

2-1/2" OD X 1-1/16" ID

X 1/4" WASHER

1"-8 X 8" A193/B7 STUD

HEXNUT

Diagram 3D.

Anchor bolt installation.

9

10/12 Rev. E

WARNING

Mast must be plumb to prevent Swing Arm from drifting.

TAPERED PLUG W/

CENTER HOLE

PLUMB BOB

Diagram 3E.

Plumbing the

mast.