IO-231

6/03

17

All furnaces are shipped with heating speed set at “B” and

cooling speed set at “D”. Use the following procedure to

select the heating and cooling speed needed for your unit.

Use the CFM LED (green), adjacent to the integrated con-

trol module fuse to verify airflow quantity. The green CFM

LED blinks once for each 100 CFM of airflow.

1. Determine the tonnage of the cooling system installed

with the furnace. If the cooling capacity isin BTU/hr di-

vide it by 12,000 to convert capacity to TONs.

Example:

Cooling Capacity of 30,000 BTU/hr.

30,000/12,000 = 2.5 Tons

2. Determine the proper air flow for the cooling system.

Most cooling systems are designed to work with air

flows between 350 and 450 CFM per ton.

Most manufacturers recommend an air flow of about

400 CFM per ton.

Example:

2.5 tons X 400 CFM per ton = 1000 CFM

The cooling system manufacturer’s instructions must be

checked for required air flow. Any electronic air cleaners

or other devices may require specific air flows, consult in-

stallation instructions of those devices for requirements.

3. Knowing the furnace model, locate the high stage cool-

ing air flow data in the following airflow tables. Look up

the cooling air flow determined in step 2 and find the

required cooling speed and adjustment setting.

Example:

A GMNTE080-4 furnace installed with a

2.5 ton air conditioning system. The air flow needed is

1000 CFM. Looking at the cooling speed chart for

GMNTE080-4, find the air flow closest to 1000 CFM. A

cooling airflow of 990 CFM can be attained by setting

the cooling speed to “C” and the adjustment to “-” (mi-

nus).

NOTE:

Continuous Fan Speed will be 38% of high stage

cooling.

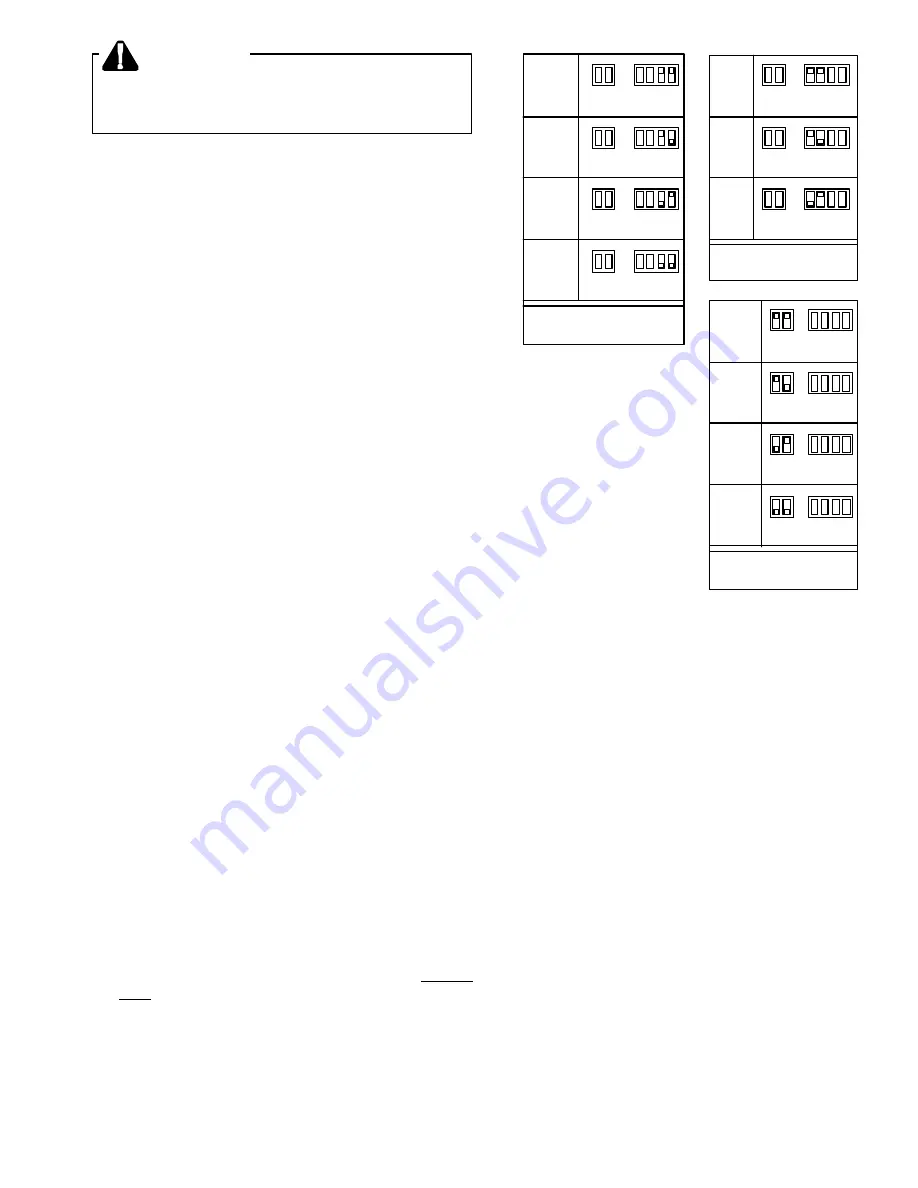

4. Locate the blower speed selection DIP switches on

the integrated control module. Select the desired “cool-

ing” speed tap by positioning switches 1 and 2 appro-

priately. Select the desired “adjust” tap by positioning

switches 3 and 4 appropriately. Refer to the following

figure for switch positions and their corresponding taps.

Turn off power to furnace for a minimum of 10 sec-

onds, allowing motor to reset and recognize new speed

selection. Turn on power to furnace and place the unit

into cooling mode. Allow blower to ramp up to full speed.

Verify CFM by counting the number of times the green

CFM LED blinks.

O

F

F

O

F

F

8 7

4 3 2 1

O

F

F

O

N

8 7

4 3 2 1

O

N

O

F

F

8 7

4 3 2 1

O

N

O

N

8 7

4 3 2 1

Cooling

Speed

Tap A

Cooling

Speed

Tap B

Cooling

Speed

Tap C

Cooling

Speed

Tap D

*

Cooling Speed Taps

(

*

indicates factory setting)

O

F

F

O

F

F

8 7

4 3 2 1

O

F

F

O

N

8 7

4 3 2 1

O

N

O

F

F

8 7

4 3 2 1

O

N

O

N

8 7

4 3 2 1

Heating

Speed

Tap A

Heating

Speed

Tap B

Heating

Speed

Tap C

Heating

Speed

Tap D

Heating Speed Taps

(

*

indicates factory setting)

*

O

F

F

O

F

F

8 7

4 3 2 1

O

F

F

O

N

8 7

4 3 2 1

O

N

O

F

F

8 7

4 3 2 1

Normal

+ (Plus)

Adjust

- (Minus)

Adjust

Adjust Taps

(

*

indicates factory setting)

*

5. Select the heating speed from the heating speed chart

in the specification sheet for your model. The adjust

setting (already established by the cooling speed se-

lection) determines which set of speeds are available.

The selected speed must provide a temperature rise

within the rise range listed with the particular model.

Example:

The GMNTE080-4 is set for 990

CFM on

cooling, the “ADJUST” is set to “-” (minus). The four

heating speeds available are “A Minus”, “B Minus”, “C

Minus”, and “D Minus”. “A Minus” has a rise of 63

°

F

for both stages which is within the 35-65°F rise range

for the GMNTE080-4. This setting will keep electrical

consumption to a minimum. Set the “Heat” speed DIP

switches to “A”.

6. Select the desired “heating” speed tap by positioning

switches 7 and 8 appropriately. Refer to figure above.

Turn off power to furnace for a minimum of 10 sec-

onds, allowing motor to reset and recognize new speed

selection. Turn on power to furnace and place the unit

into heating mode. Allow blower to ramp up to full

speed. Verify selected CFM by counting the green

CFM LED blinks.

WARNING

TO AVOID DEATH OR PERSONAL INJURY DUE TO ELEC-

TRICAL SHOCK, TURN OFF POWER TO THE FURNACE

BEFORE CHANGING SPEED TAPS.