16

Step 4: Assemble the Engine Mount:

Although GSRC had intended to have the engine mount blind-nuts pre-mounted, but in order

to provide the assembler with the most engine mounting flexibility we allow the assembler to

decide the engine mount orientation. We will show how to side-mount an engine. We will be

showing an YS-110FZ®; however, the procedure will be similar for other engines. Take note and

pre-plan for the mounting and thoroughly consider the implications of the muffler and needle

valve locations.

There is ~ 2° right thrust offset built into the fuselage firewall.

Install Engine Mount Blind-nuts:

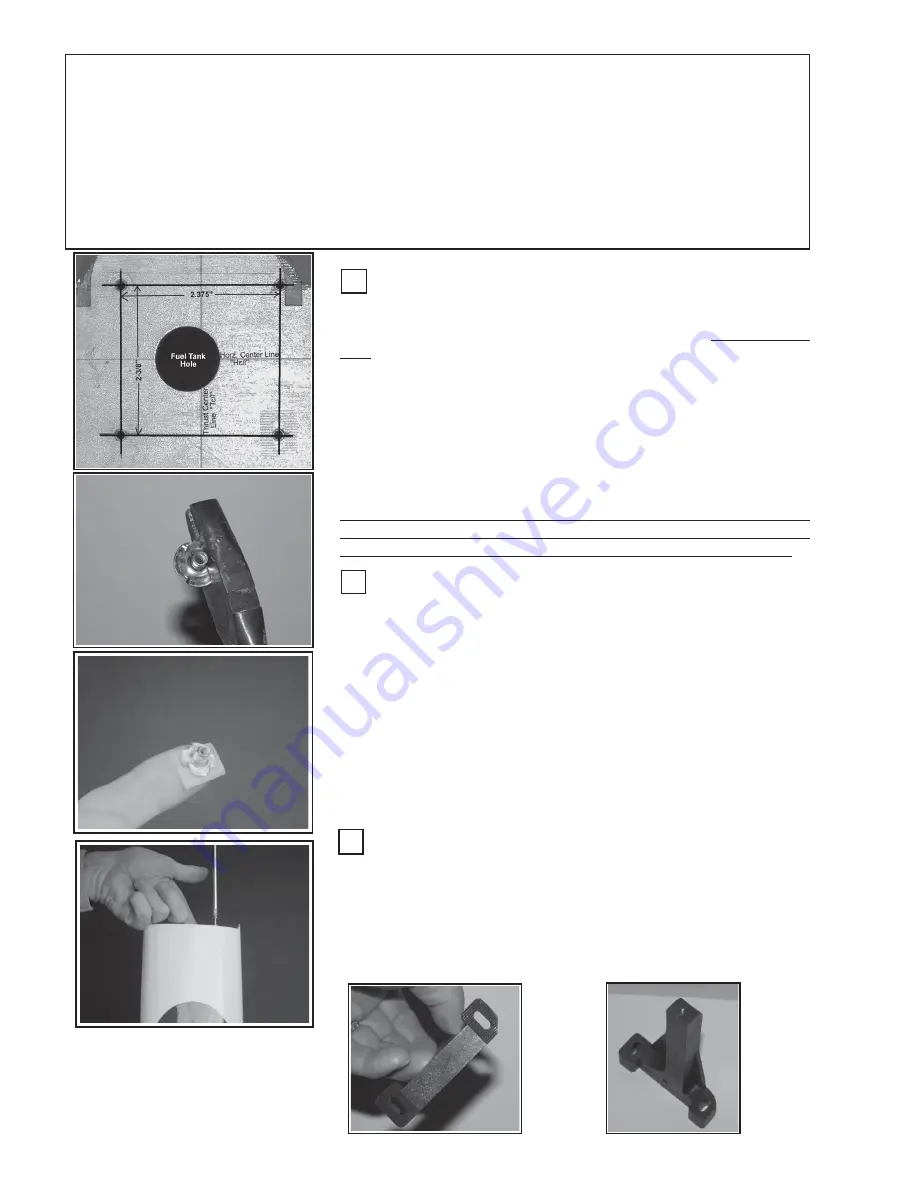

Cut the side off one of the blind nuts as shown. This nut goes in the

upper-left corner. Place a washer on one of the engine-mount bolts and

have it and a 7/16” hex-driver at hand. Using a piece of tape, make a

loop and stick it to the end of your index finger. Place a blind-nut on the

tape as shown, left. Orient the blind-nut through the fuel tank hole and

under

one of the firewall bolt holes. Using the engine-bolt & washer,

thread the bolt into the blind-nut. Tighten with the hex-driver to d r a w

the blind-nut into the back side of the firewall. Repeat this process

for the remaining three engine-mount holes.

Note

that the firewall has been marked with the fuel-tank tubing informa-

tion. Refer to the fuel tank assembly step for fuel-tank tubing (port) orientation.

The markings refer to: 1) Muffler or Vent port, 2)

Carburetor port, 3) Fill

port (the 3rd filling port is optional)

Locate the Engine Mounting Holes:

Locate the Horizontal (Hc/l) and Thrust Center Lines (Tc/l). If they

are not visible, measure and draw them in. Draw two (2) parallel lines,

one 1-3/16” to the right and the other 1-3/16” left of the

Thrust Center

Line

.

The distance the two engine mount rails are to be set apart is de-

pendant upon the engine you will be using. Refer to Table 2, (p 46) for

specific engine details. If you engine is not listed, measure the engine

crankcase width just below the engine’s mounting tabs. Add 0.350” to

this dimension (the result will be termed “

A

”) and then divide the number

“

A

” by two (2). The resulting distance will be termed “

B

” Draw two (2)

parallel lines, at “

B

” inches above and below, Hc/l. Where the four lines

cross, center punch and drill 13/64” diameter holes for the blind nuts.

Depending upon the size and type engine you use, you may need to

rotate the entire bolt-hole pattern 2-3 deg. CCW to get the engine inside

the cowl. Do this now if you have any doubts if the engine will fit in.

Modify Upper Mount:

Cut of the corner of the upper engine mount as shown and

check fit on the firewall to be sure the mount will fall within the firewall

perimeter. Temporarily attach the engine mounts using the four

engine mounting bolts and washers. Snug it down tight; however, it

will be removed later to drill the engine mounting holes in the engine

mount rails.

V

C

F

Содержание Bampf 3D Extreme

Страница 50: ...50 ...

Страница 51: ...51 Notes ...

Страница 52: ...52 This Page intensionally left blank ...