Glue Machinery Corporation

Champ™ Stick 400 Manual

Part # G25E03-001

Glue Machinery Corporation™

4234 Boston St, Baltimore, Maryland 21224

Toll Free 1-888-202-2468 | Phone: 410-761-2727 | Fax: 410-761-5127 | Email:

www.gluemachinery.com

Tips on Using:

The following guide provides helpful information for G25E03-001/CHAMP™ STICK 400 glue gun and

hot melts adhesives.

1.

The normal working time of the hot-melt is thirty (30) seconds. After the adhesive has been extruded

onto the bonding surface, the part should be pressed together within fifteen to twenty (15-20) seconds.

The bond will have about 90% of its bond strength in one minute.

2.

The working time of the hot-melt can be extended to fifty to sixty (50-60) seconds by applying the

adhesive in large drops (11mm diameter) or shortened to less than ten (10) seconds by extruding the

adhesive in a thin line.

3.

Large areas are difficult to bond because the adhesive often hardens before you have extruded the

required amount. Use a higher volume hot melt system from Glue Machinery Corporation such as the

Champ 3, 600, 10 or Economelt.

4.

Preheating the bonding surface to slightly above room temperature will improve the bonding strength.

This action is particularly important when gluing metal pieces.

5.

The hot-melt adheres well to porous surfaces like paper, cloth, particleboard, and wood.

6.

The hot-melt adhesives quick set time eliminates the need for clamps or other holding devices.

7.

The hot-melt begins to soften when the temperature exceeds 140ºF and should not be used for items

that will be subjected to temperatures above that. Other hot melts are available with high softening

points that must be processed with bulk Hot Melt Systems available from Glue Machinery

Corporation.

8.

Hot-melt adhesives can be used in place of nails, staples, tape, or liquid glue: however, they should

not be used to replace structural fasteners where heavy loads are involved.

9.

Glue can string from the nozzle. If your glue is stringing from the nozzle you may want to swirl the

nozzle in a circular motion so the heat of the nozzle will cut the string. If the glue string lands on your

component, allow the glue to cool, then use a hair dryer and blow off the glue string. Adjustments to

the temperature and nozzle can also help reduce stringing. Glue strings can also be reduced with

higher temperature and smaller nozzles.

Operation:

1.

Plug the glue gun into any 110 AC outlet with required specification; red light on means the power is

on.

2.

Allow the tool to heat for 10 to 15 minutes before using. Insert a stick of adhesive (7/16”/11.2 mm

diameter) into the back of the tool.

3.

When the gun is fully heated, squeeze the trigger slowly until the melted material begins to flow from

the nozzle. Release the trigger to stop the glue flow.

4.

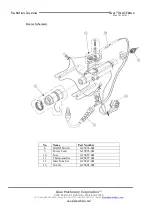

The output volume per trigger stroke can be adjusted by adjusting the patented stroke adjustor screw.

5.

Different nozzle tips are available for different gluing applications and output amount.

6.

Use the included screwdriver to adjust the operating temperature for which that glue stick is designed.

Gun temperature is adjustable from 284F to 428F (140C-220C)

7.

Use the glue gun trigger to adjust the output and speed of the glue sticks.

8.

Never pull sticks out of the back of the gun once inserted.

Save these safety rules for future use:

1.

It is normal for this tool to become very warm during use. This does not indicate a problem.

2.

The glue gun should be turned off and unplugged after use or if it will not be used within 1-hour

period. The adhesive can be stored indefinitely in the unheated gun and re-melted by heating up the

tool.

3.

If you accidentally touch the molten hot glue, immediately immerse the affected area in cold water

and call a doctor. The injured area should be attended by a medical professional.

4.

Some materials are heat-sensitive and can be damaged by the hot nozzle or even the hot glue.

Whenever possible, test a piece of scrap material or a hidden portion of the object being repaired.

5.

If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similar

qualified person in order to avoid a hazard.