Supplied By www.heating spares.co Tel. 0161 620 6677

15

220459C

8 Commissioning

8.1 All Systems

Make sure that the system has been thoroughly flushed

out with cold water without the pump in place.

Refit the pump, fill the system with water, ensuring that

all air is properly vented from the system and pump.

Before operating the boiler check that all external

controls are calling for heat.

8.2 Sealed Water Systems Only

Flush the whole of the system with cold water without

the pump in place. Refit the pump and fill until the

pressure gauge registers 1.5bar (21.5lbf/in

2

). Clear any

air locks and check for water soundness.

Check the operation of the safety valve, by allowing the

water pressure to rise until the valve opens. The valve

should open /- 0.3 bar (+/-4.3lbf/in

2

) of the 3bar

preset pressure. Where this is not possible conduct a

manual check and test.

Release cold water to initial system design pressure.

The set pointer on the pressure gauge should be set to

coincide with the indicating pointer.

8.3 Initial Lighting and Testing

Refit the outer case, see diagram 5.1.

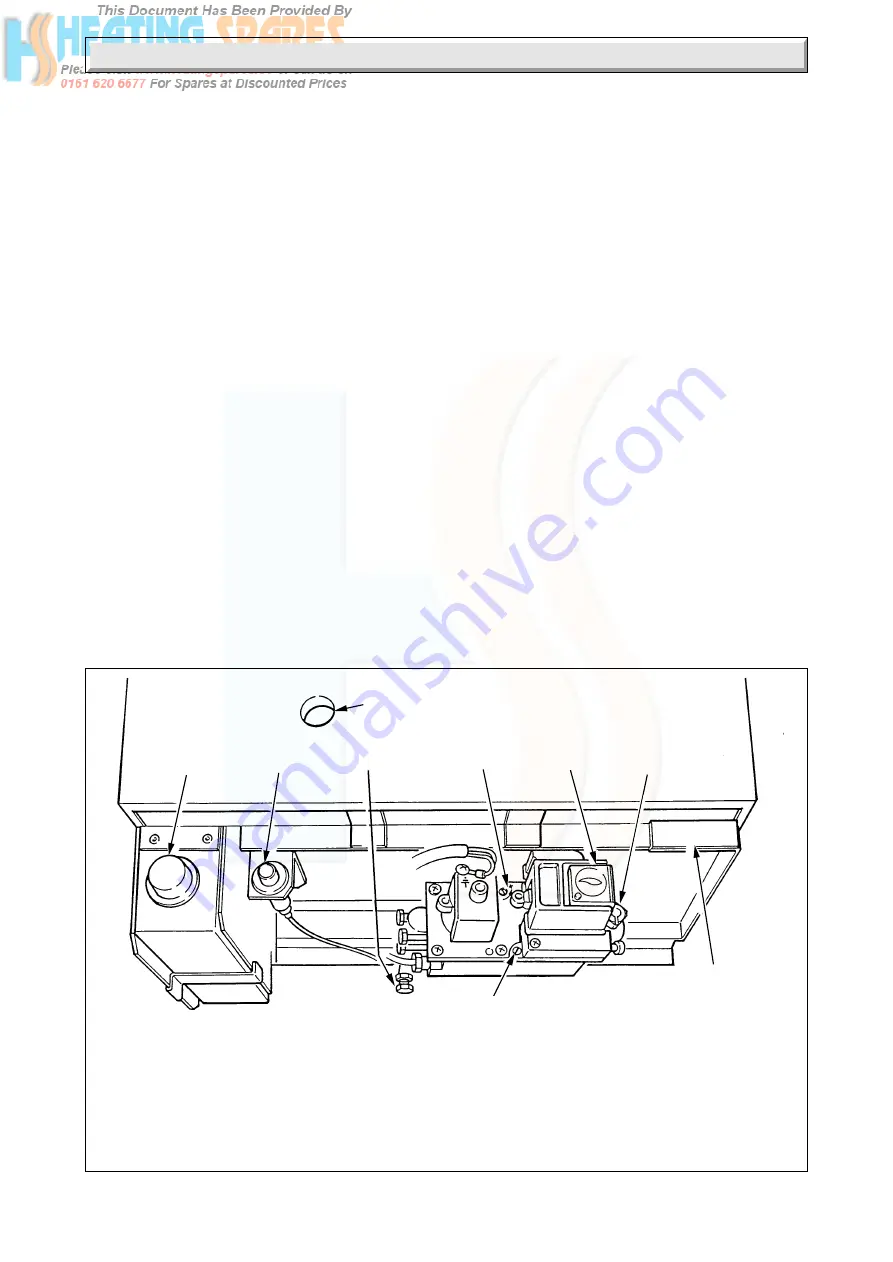

Identify the controls by reference to diagram 8.1.

Turn boiler thermostat to “O” the Off position.

Remove the gas pressure test point screws “K” and fit a

suitable pressure gauge.

Turn the electrical supply on and check that the pump is

working.

OPEN ALL WINDOWS AND EXTINGUISH ANY

NAKED LIGHTS, PIPES, CIGARETTES etc.

Turn on the main gas supply and purge in accordance

with the current issue of BS6891.

Turn boiler gas service cock “J” to On.

Depress control button “B”, keep pressed in and at the

same time operate the piezo unit button “C” until the

pilot burner lights. After the pilot burner lights keep the

button “B” depressed for about 15 seconds. If the pilot

fails to stay alight a safety device prevents immediate

relighting. Do not attempt to relight until the safety

device has reset. Check the length of the pilot flame, it

should envelop the thermocouple tip as shown in

diagram 10.3. The pilot rate can be adjusted by turning

screw “H” having first removed the gas valve cover by

releasing the screw. Test pilot supply connection for gas

soundness with a suitable leak detection fluid.

BOILER CONTROLS

Diagram 8.1

A. BOILER THERMOSTAT

H. GAS RATE ADJUSTMENT SCREW

B. GAS CONTROL KNOB

H.

(UNDER COVER SCREW)

C. IGNITION BUTTON

J. GAS SERVICE COCK

G. VIEWING WINDOW

K. PRESSURE TEST POINT

L. PILOT BURNER

L.

ADJUSTMENT SCREW

J. (SHOWN OFF)

B

H

G

L

MODEL AND

SERIAL NUMBER

A

C

K

2416