14

DOK41 HOIAO C0DEN · FD 9912

www.gdts.one

English

Air-to-water heat pump 9 - 12 kW

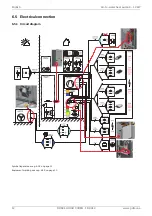

6.5.4 Electrical connection general

All connection cables must be provided on-site. The cable type

(cross-section, conductor type, etc.) must be chosen taking

into account the relevant electrical parameters (e.g. power, cur-

rent, voltage, etc.) and the applicable VDE, EN and VNB regula-

tions. Information on this can be found in the device informa-

tion and the electrical documentation as a planning aid.

!!

ATTENTION!

The plugs are protected against being pulled. They must be

released with a small screwdriver before disconnecting.

6.5.5 Electrical connection indoor unit

For operating the heat pump, at least the following cables / sig-

nals must be connected:

Supply voltage / refrigeration circuit

An all-pole disconnecting device with a contact gap of at

least 3 mm (e.g. utility blocking contactor or power contac-

tor) must be installed in the refrigeration circuit power sup-

ply. A 3-pole circuit breaker with joint tripping of all outer

conductors (trip current in accordance with device infor-

mation) provides the short circuit protection taking into ac-

count the layout of the internal wiring. The relevant com-

ponents in the heat pump contain an internal overload

protection.

For connecting on the switch box of the refrigeration cir-

cuit modules on +A100-X1, check for the clockwise rotat-

ing field of the load feed.

Phase sequence: L1, L2, L3.

!!

ATTENTION!

Ensure that there is a clockwise rotating field: With incorrect

wiring the starting of the heat pump is prevented. A relevant

warning is shown.

Communication / control voltage (hydraulics <-> refrigera-

tion circuit)

The communication and control voltage cable from the hy-

draulic switch box (with heat pump manager) to the refrig-

eration circuit module are already pre-wired and end on the

plugs +A100-X2 (control voltage) and +A100-X5.1 (com-

munication). These may only have to be inserted.

Control voltage

The three-core supply cable for the heat pump manager

(+A200-N1) is fed into the heat pump to the hydraulic

switch box +A200-X2. The supply cable (L/N/PE ~230 V,

50 Hz) must have a continuous voltage. For this reason, it

should be tapped upstream from the utility blocking con-

tactor or be connected to the household current, because

otherwise important protection functions could be lost

during a utility block.

Utility block

The utility blocking contactor (K22) with 3 main contacts

(1/3/5 // 2/4/6) and an auxiliary contact (NO contact 13/

14) should be dimensioned according to the heat pump

output and must be supplied on-site. The potential-free

NO contact of the utility blocking contactor (13/14) is

wired to the hydraulic switch box and must be connected

on the relevant plug +A200-XK22 there.

Caution! Extra-

low voltage!

External sensor

The external sensor is connected to the hydraulic module

via the +A200-XR1 plug

Supply voltage hydraulics

For the power supply to the 2nd heat generator, a wire

must be routed to the device according to the power and

connected to the hydraulic switch box on plug +A400-X1.

In delivery state, the 2nd heat generator is configured to

6kW to guarantee that the increased heat consumption is

met while drying out the building. In regular operation, this

must be adapted to the actual required additional heating

output (integrated system label).

To reduce it to 4 or 2 kW, one or two connections between

+A400-K20 (relay 2nd heat generator) and +A400-F17

(safety temperature limiter)- both located in the hydraulic

switch box - must be removed.

6.5.6 Electrical connection outdoor unit

A power supply (plug +A110-X1 <-> +A100-X5.2) and commu-

nication line (plug +A110-X5 <-> +A100-X5.2) must be routed

parallel to the split line between the refrigeration circuit and the

outdoor unit.

HINWEIS

ºº

º

ºº

º

NOTE

The assignment of the heat pump manager is outlined in the

Quick Installation Guide. The functions are also printed on the

label field of the heat pump manager

6.5.7 LAN / network connection

The heat pump is only designed for connection to the internet

via a router. This ensures that the user can access the system at

any time for setting parameters or for reading out information.

Maintenance work or software updates are much easier.

A conventional network cable (Cat. 5) is required for connec-

tion, which is connected between an external router (+A350)

and the network interface (+A210) of the indoor unit.