Page 14

1.0 DESIGN

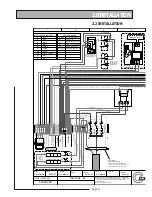

1.3 SYSTEM DETAILS

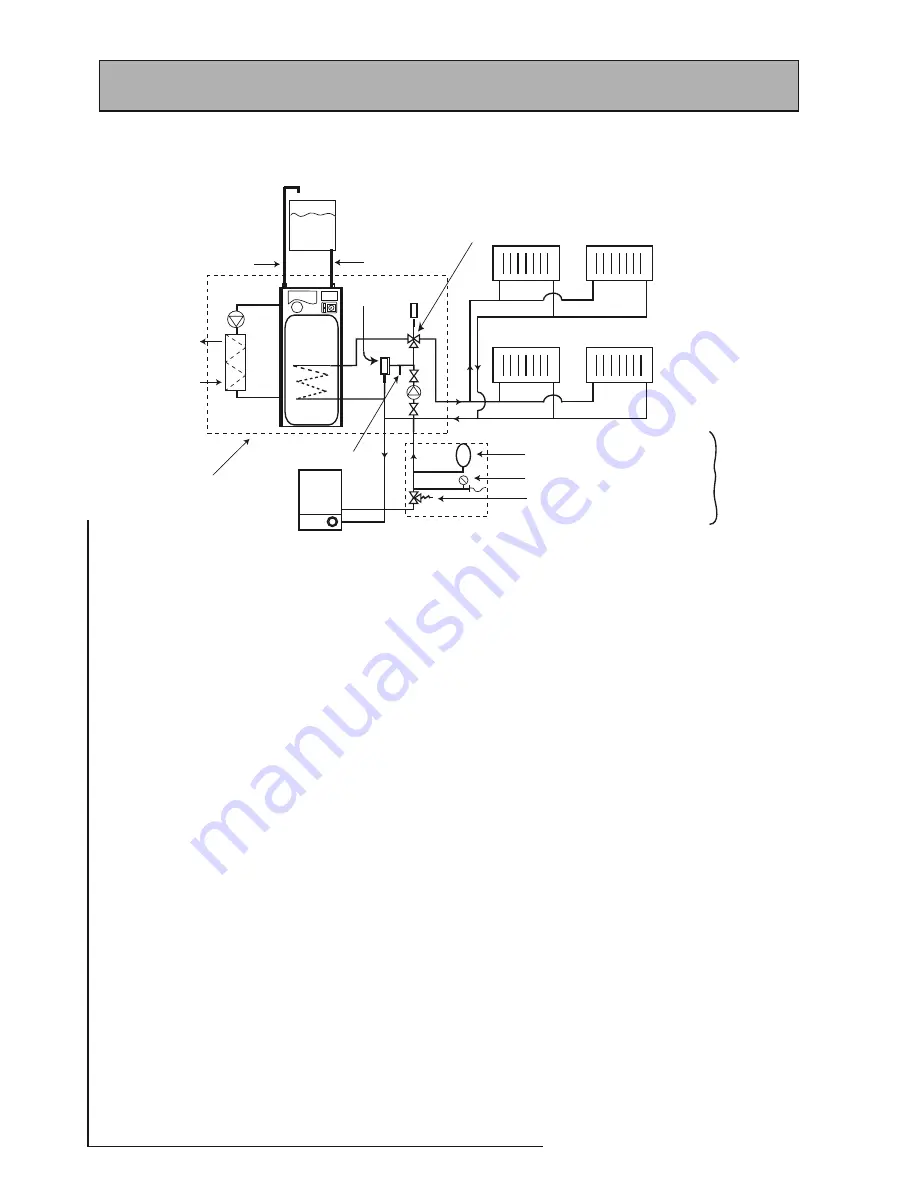

Remote

F&E

Cistern

BM

A-Class

SP

Boiler

Cold feed

Open Vent

Heating Circuit

Hot Out

Mains Cold In

Components fitted

within appliance case

Expansion Vessel

Pressure Gauge/Filling Loop

Pressure Gauge Relief/Safety Valve

Optional

sealed system

kit

3 port divertor valve

Automatic

bypass valve

Summer use towel

rail blanked connection

Heating System

General

A schematic layout of the heating system in a typical small dwelling is shown

above.

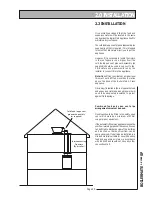

The fl ow and return from the boiler must always run directly to the BoilerMate A-Class

SP and the fl ow should rise continuously to facilitate venting. The heating circuit is

taken from the BoilerMate A-Class and is piped in the conventional manner.

The BoilerMate A-Class SP is only suitable for a sealed heating system and therefore

boiler/heating pipework can run at a higher level than the store.

It is recommended that the F & E cistern for the appliance is fi tted at high level in the

same cupboard as the BoilerMate. However, it can be fi tted remotely up to 6m above

the base of the BoilerMate A-Class i.e. the maximum static pressure in the store must

not exceed 0.6 bar.

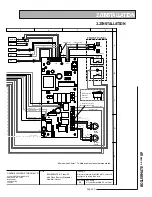

The performance of the system pump and the pressure losses through the SysteMate

2000 primary coil circuit are shown in1.2 Technical Data. The nett pump head available

for the heating circuit can be determined from these fi gures and this nett pump head

should be used for sizing the heating circuit pipework.

For example: At 24 litres/min primary fl ow rate, the pressure loss through the

SysteMate 2000 model SM210 (coil and fi ttings) is 2.1m W.G. (21kPa). The maximum

pump head available at 24 litres/min and setting 3 is 3.2m H

2

O (32kPa), therefore 1.1m

W.G. (11kPa) is available for the boiler circuit.

With sealed heating systems air is released during the fi rst few weeks of operation.

This will need to be vented and the system re-pressurised.

If the automatic model is being used the overfl ow/warning pipe should be installed

in a material suitable for a heating system feed and expansion cistern in accordance

with BS 5449.

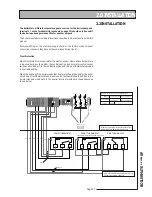

An automatic bypass is fi tted on the BoilerMate

A-Class SP to compensate for pressure (i.e. fl ow)

rate changes in the heating circuit e.g. when the

thermostatic radiator valves close. The system

does not require any other bypass valves but

a bypass radiator used in conjunction with a

room thermostat can be used if required to

provide a boiler interlock. The bypass valve

must be set by the installer to suit the system

ie to provide minimum fl ow required for the

boiler when all TRV’s are closed.

There shall be no permanent connection to

the mains water supply for fi lling the system,

even through a non-return valve without

the approval of the Local Water Authority.

An approved filling loop is required with

the BoilerMate A-Class (available as part of

an optional extra kit) which this should be

disconnected after commissioning the system.

This should be located adjacent to the boiler

along with a suitable expansion vessel gauge

and pressure relief valve (also available as part

of the optional extra kit) as shown above.

Содержание BMA 120 SP

Страница 44: ...Page 44 ...

Страница 45: ...Page 45 BOILERMATE A CLASS SP ...