62 |

Wheel & Rim Safety Manual

5

6a

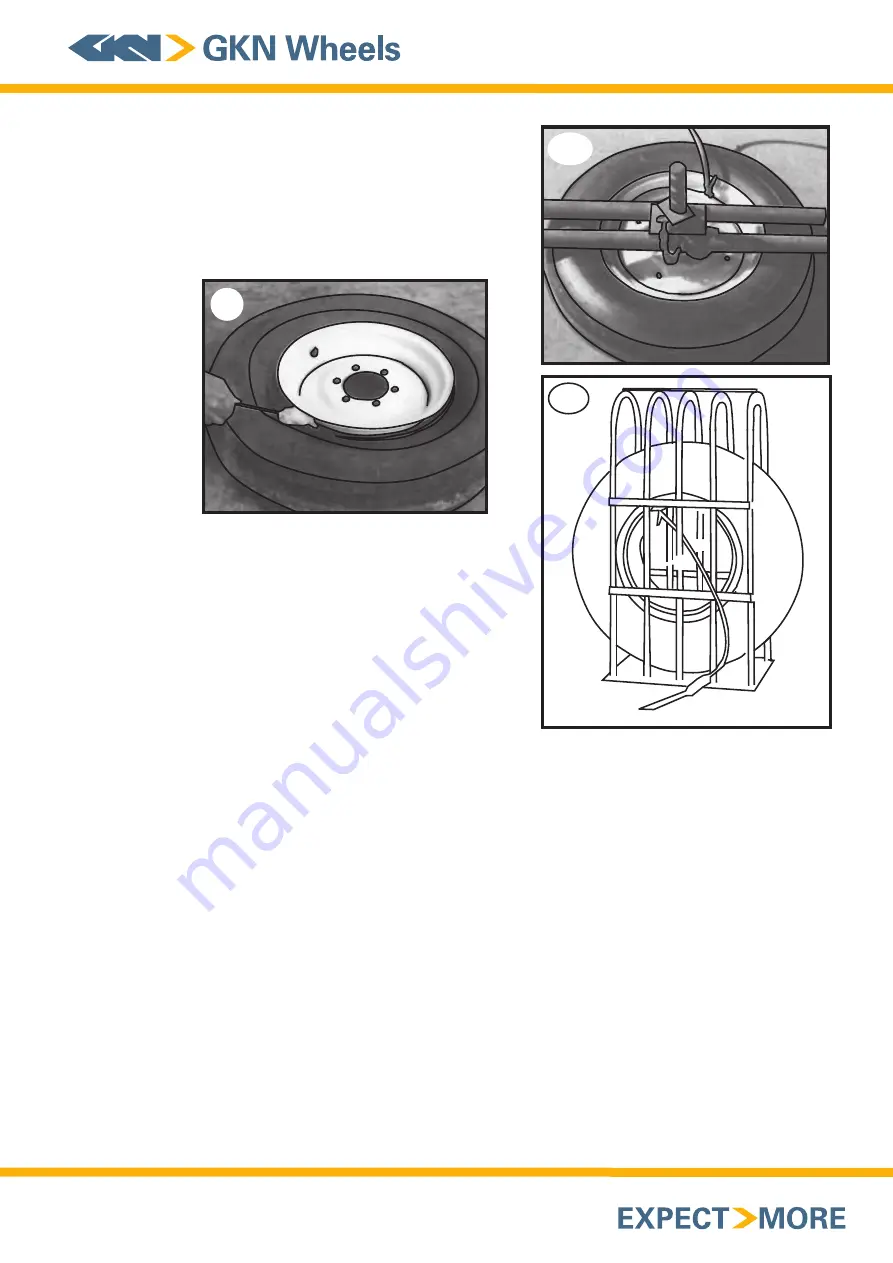

6. Centering the tire on the rim is extremely

important to prevent broken beads. Place in a

safety cage or other restraining device. Using an

extension hose with an in-line gauge and clip-on

air chuck, inflate the tire (with the valve core

removed) to seat the beads. DO NOT EXCEED 35

PSI (240 kPa). It is essential to stand clear of the

tire while inflating it. Check to see that both

beads are seated all the way around the tire.

If the tire is tube-type, completely deflate it

(to allow repositioning of the tube) by removing

the valve core housing.

For tubeless tires, mounting depends on how

well the tire’s shape has been maintained. If the

beads are in or near their molded position, they

can be seated by inflating the tire, through the

valve spud. Where the beads have been

squeezed together, the use of an inflator ring

(either horizontally or vertically) will be required

to provide a seal between the tire bead and rim.

Re-insert the valve core and inflate the tire again

to the recommended operating pressure.

5. Thoroughly lubricate the tire bead area and

rim bead seats on both sides of the tire.

6b

Содержание Wheel & Rim

Страница 1: ...Wheel Rim Safety Manual...

Страница 74: ...73 Wheel Rim Safety Manual GKN OffHighway Wheels Products...