8

12) Tighten the tension screws

(29C) to 310 in.-lbs. (35NM).

The plunger pipe (29B) should

not be strained by over tight-

ening of the tension screw

(29C) or through damage to

the front surface of the plung-

er; otherwise, it will probably

break.

13) Place entire manifold/seal

sleeve assembly over the

studs and push firmly until

seated against the crank-

case.

LP200-SS Repair Instructions

14) Tighten hex nuts (49A) in a

crosswise pattern (shown

above) to 59 ft.-lbs. (80

Nm).

LP200-SS Torque Specifications

Position

Item #

Description

Lubrication Info

Torque Amount

1

07759

Crankcase

Molycote Cu-Paste

6

05943

Oil Sight Glass

Loctite 572

29 ft.-lbs. (40 Nm)

10

01010

Cylinder Screw

221 in.-lbs. (25 Nm)

12

07109

Plug, 1/2” BSP

29 ft.-lbs. (40 Nm)

17

07114

Hexagon Screw

221 in.-lbs. (25 Nm)

24

13340

Inner Hex Screw, Connecting Rod

22 ft..-lbs. (30 Nm)

29C

13031

Tension Screw, Plunger

Loctite 243

26 ft.-lbs. (35 Nm)

29D

07161A-0100

Seal Sleeve

Loctite 577

31

07133

Radial Shaft Seal

Loctite 403

48

06077

Plug, Discharge

107 ft.-lbs. (145 Nm)

49

07157

Stud Bolt

Loctite 270

49A

07158

Hexagon Nut, Stud Bolts

59 ft.-lbs (80 Nm)

Содержание LP200-SS

Страница 4: ...4 Exploded View LP200 SS...

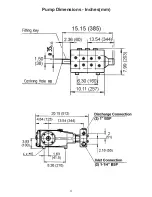

Страница 11: ...11 Pump Dimensions Inches mm...