21

XLp Installation & Configuration, June 2010

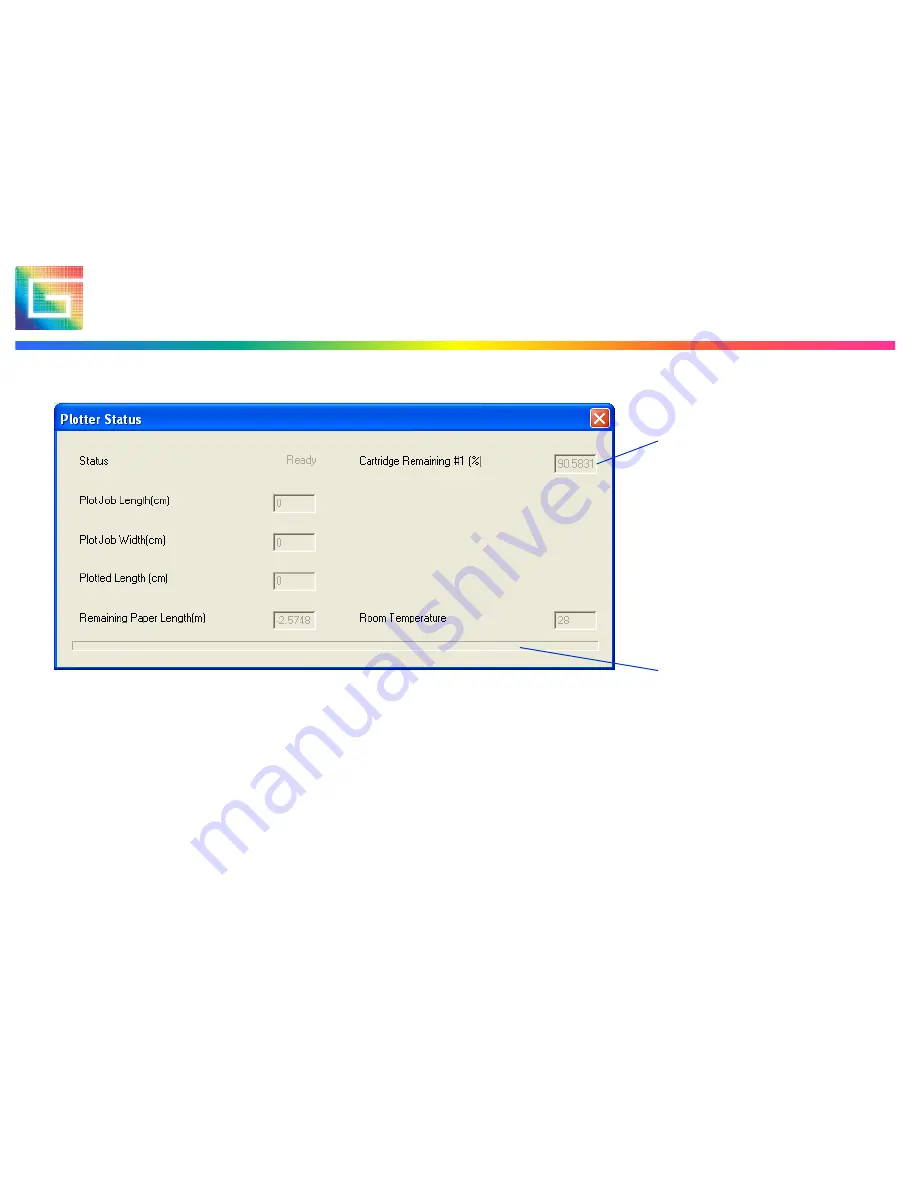

XLp Interface: Plotter Status

Percentage of ink

remaining in cartridge

(estimate)

Progress bar to indicate

how much of the current

job has been send to the

XLp

This window will allow you to monitor the ink levels

in the cartridges, check the status of the plotted job

(length and width) and monitor the remaining paper

and even show the temperature inside the plotter.

Содержание XLp

Страница 5: ...5 XLp Installation Configuration June 2010 Overview Technical Specifications...

Страница 17: ...17 XLp Installation Configuration June 2010 Software installation...

Страница 19: ...19 XLp Installation Configuration June 2010 Gerber Device Configuration Select this plotter type...

Страница 41: ...41 XLp Installation Configuration June 2010 Components left side...

Страница 42: ...42 XLp Installation Configuration June 2010 Components Operator Side...

Страница 43: ...43 XLp Installation Configuration June 2010 Questions...